Granulated colorant and related art

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

(1) Production of Granulated Colorant (Nigrosine Dye: Water=100:35)

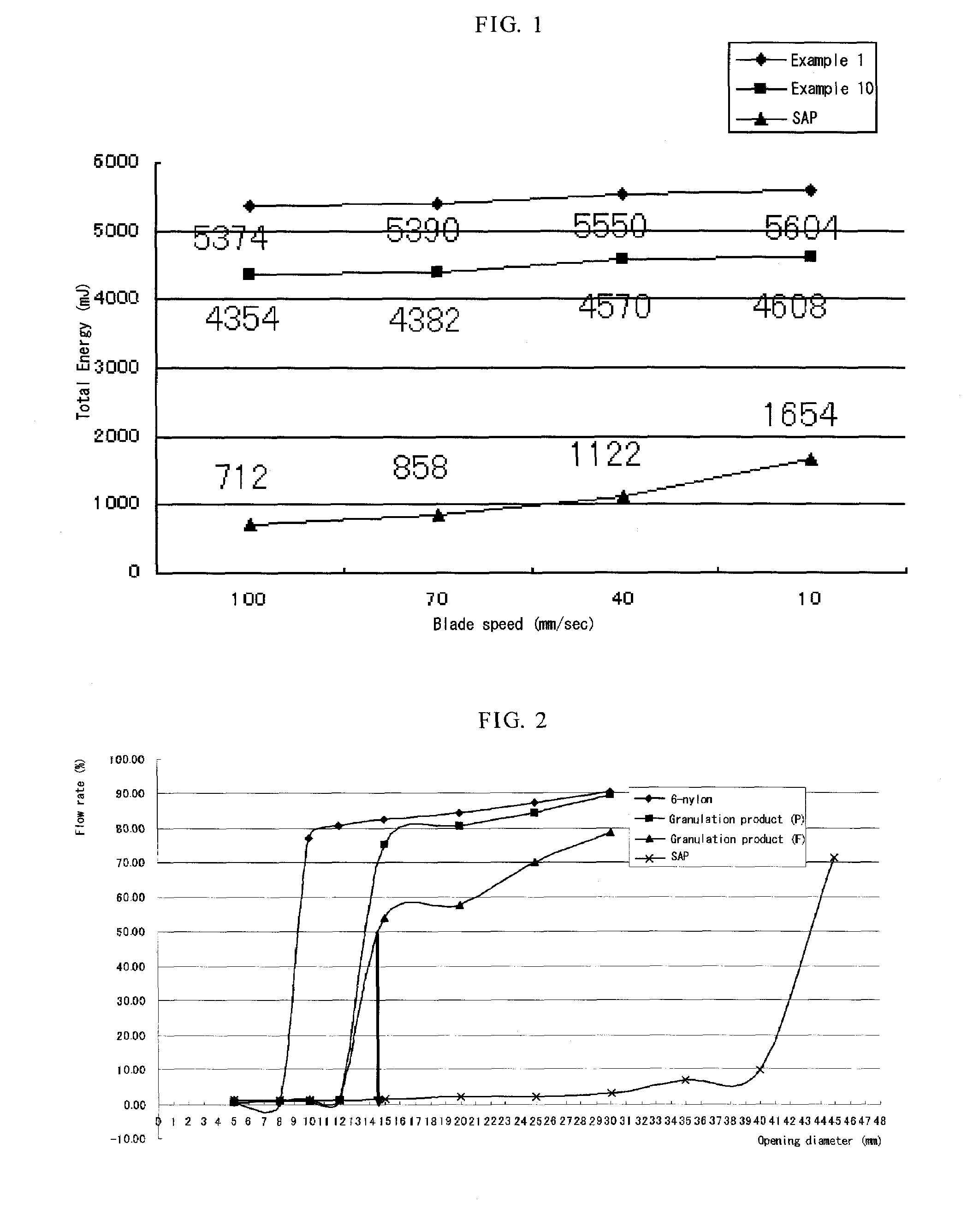

[0084]After 2000 g of Nigrosine Base SAP (name of a product manufactured by Orient Chemical Industries, Ltd.; a nigrosine dye as C.I. Solvent Black 7, having a specific surface area of 3.50 m2 / g, an average particle diameter of 7 μm, an Fe content of 6000 ppm, an aniline content of 1.50% by weight, a nitrobenzene content of 0.1% by weight, and a product pH of 5.1) and 700 g of water were blended in a kneader for 3 minutes, the blend was removed.

[0085]This blend was subjected to extrusion granulation treatment using an extrusion granulating machine (Disc Pelletter F-5 model, a commercial product manufactured by DALTON Corporation) with a selected disc die opening diameter of 3 mm, while adjusting the roller revolution speed (120 rpm) and keeping a constant roller pressure (100 kg / cm2), to yield a wet colorant comprising a cylindrical pellet (granulation product) and partially ungranulated material. This pellet was rem...

example 2

(1) Production of Granulated Colorant (Nigrosine Dye:Water=100:35)

[0088]After 2000 g of Nigrosine Base SAP and 700 g of water were blended in a kneader for 3 minutes, the blend was removed. This blend was subjected to extrusion granulation treatment using an extrusion granulating machine (Disc Pelletter F-5 model) with a selected disc die opening diameter of 2 mm, while adjusting the roller revolution speed and keeping a constant roller pressure, to yield a wet colorant comprising a cylindrical pellet (granulation product) and partially ungranulated material. This pellet was removed and its hardness was determined to be 1.96 N using a hardness meter (KIYA type hardness meter: WPF1600). The bulk density of the granulation product was 0.59 g / ml.

[0089]The wet colorant obtained was dried at 70° C. for 5 hours to yield a colorant containing 80% by weight of a cylindrical pellet. The colorant obtained was sieved to yield a cylindrical pellet of ø1.92 mm×9.37 mm (granulated colorant A-2). ...

example 3

(1) Production of Granulated Colorant (Nigrosine Dye:Water=100:47.8)

[0091]After 2000 g of Nigrosine Base SAP and 950 g of water were blended in a kneader for 3 minutes, the blend was removed. This blend was subjected to extrusion granulation treatment using an extrusion granulating machine (Disc Pelletter F-5 model) with a selected disc die opening diameter of 5 mm, while adjusting the roller revolution speed and keeping a constant roller pressure, to yield a wet colorant comprising a cylindrical pellet (granulation product) and partially ungranulated material. This pellet was removed and its hardness was determined to be 6.86 N using a hardness meter (KIYA type hardness meter: WPF1600). The bulk density of the granulation product was 0.60 g / ml.

[0092]The wet colorant obtained was dried at 70° C. for 5 hours to yield a colorant comprising 78% by weight of a cylindrical pellet. The colorant obtained was sieved to yield a cylindrical pellet of ø4.93 mm×15.48 mm (granulated colorant A-3...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

| Percent by mass | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com