Microfabricated tools for manipulation of small samples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

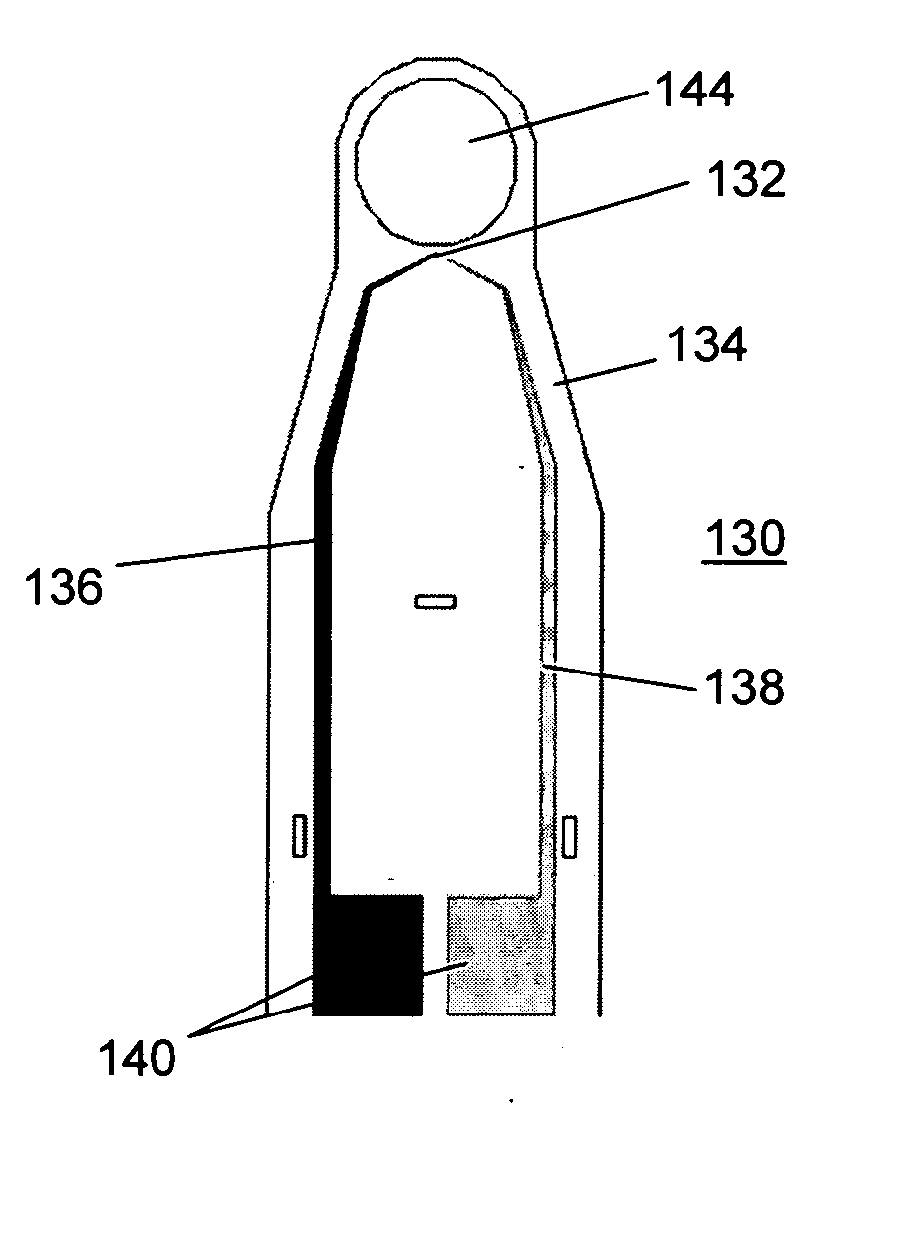

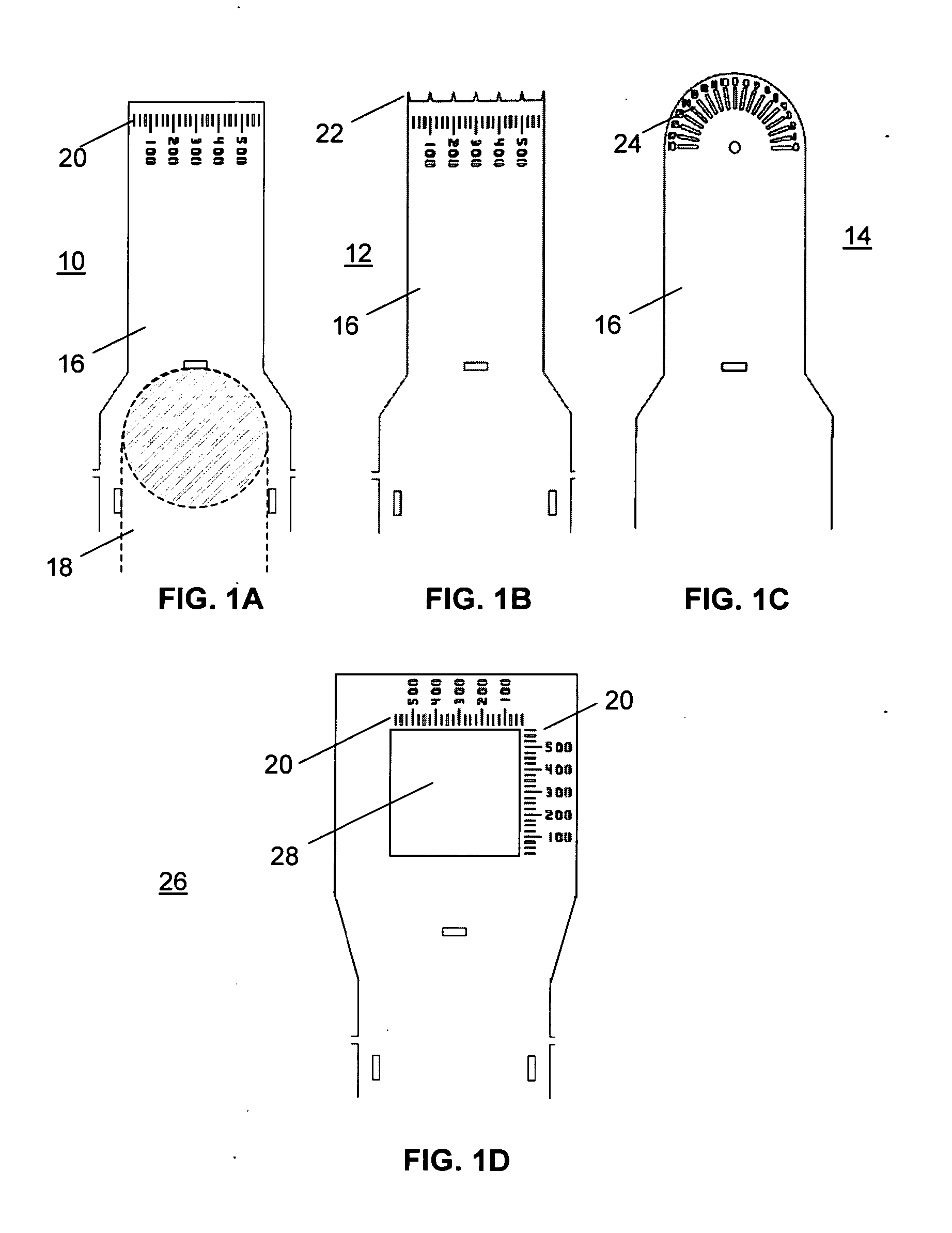

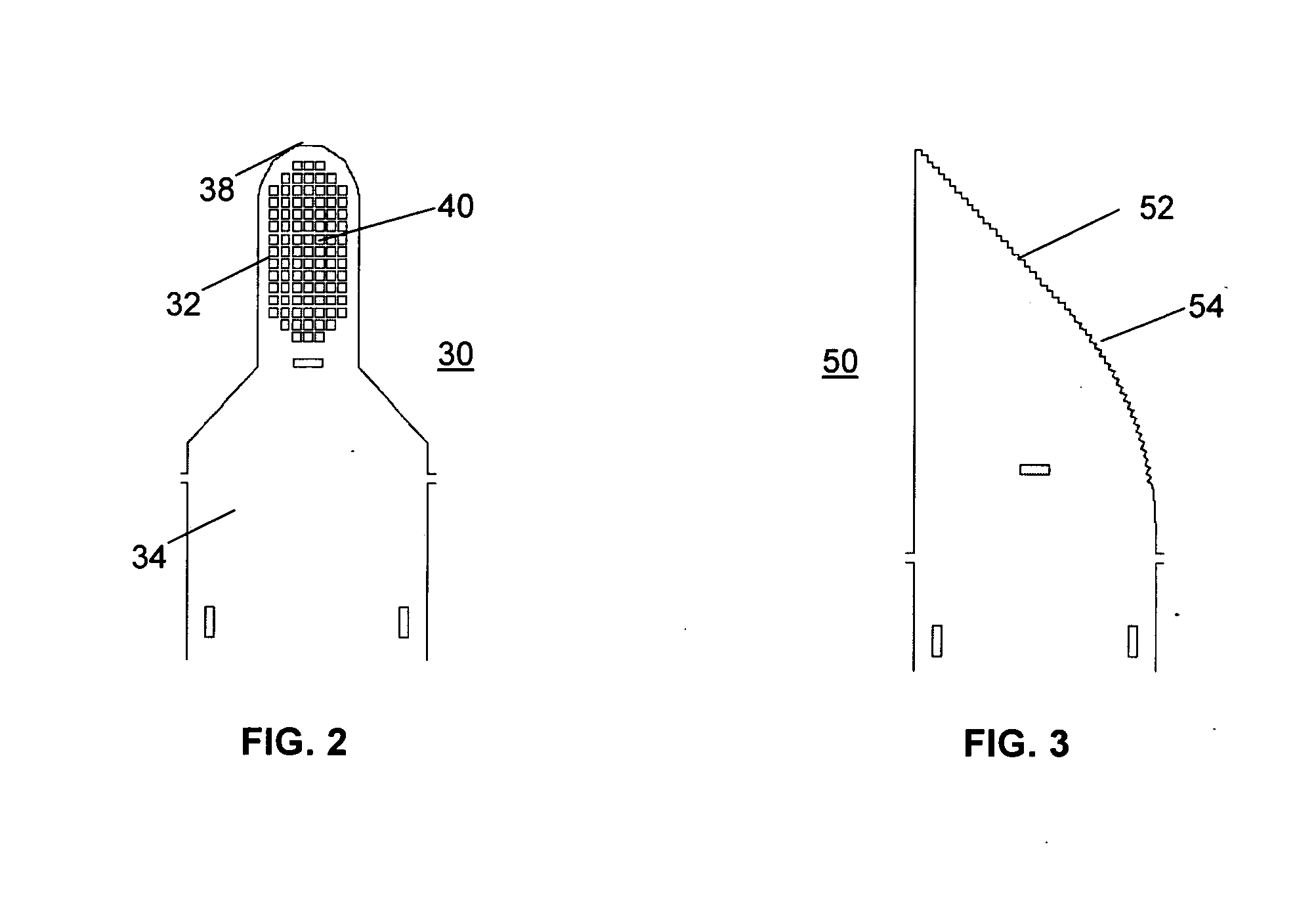

[0025] With reference now to a more detailed consideration of the various preferred embodiments of the present invention, fundamental to each of the microfabricated tool designs is that each is formed from thin film pieces, which are preferably, though not necessarily, wrapped around a cylindrical post. In the tools that use the cylindrical post, horizontal and vertical slits in the lower portion of the films define the positions of the top and sides of the cylindrical post. Preferably, the films are formed from a polymer (plastic), such as polyimide or mylar, which is 5-50 micrometers thick, preferably 10 micrometers, has a very soft spring constant and is less likely to damage fragile samples than, e.g., metal tools. The thinness allows the tip to be easily flattened against a hard substrate, e.g., a glass or plastic surface during measurements. The films have lateral dimensions 1 mm or smaller and are preferably produced by microfabrication methods. In addition, the films are pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com