Diamond Electron Emission Cathode, Electron Emission Source, Electron Microscope, And Electron Beam Exposure Device

a technology of electron beam and emission cathode, which is applied in the manufacture of discharge tube main electrodes, electrode systems, electric discharge tubes/lamps, etc., can solve the problems of high replacement cost, high service life of discharge tubes, and high cost of discharge tubes, and achieves high throughput, small energy width, and high brightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

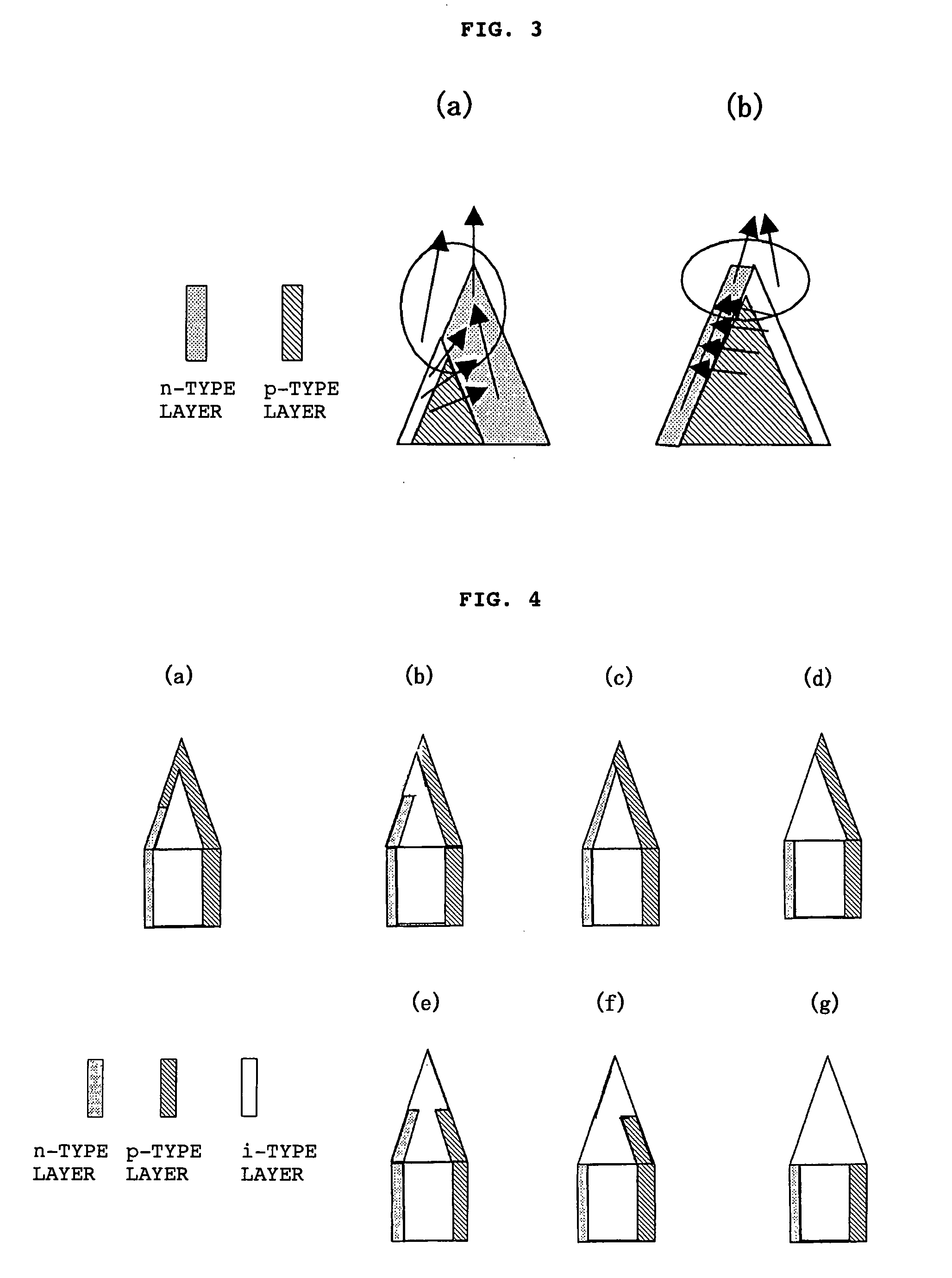

[0077]Single crystal diamond substrates obtained by high-pressure synthesis and single crystal substrates obtained by vapor phase synthesis, all having the shape of an elongated rectangular parallelepiped, were subjected to sharpening in order to prepare samples having a sharp tip end, as shown in FIG. 10(a). Diamonds subjected to doping of various types were synthesized on those substrates. The synthesis of diamonds was conducted by a microwave CVD method by using hydrogen gas and methane gas.

[0078]The tip end diameter could be roughly adjusted during polishing, and representative samples with a tip end diameter of about 1 μm and about 10 μm were prepared. The tip end can be also sharpened to a submicron level by diamond re-growth or vertical etching using plasma or ions.

[0079]When an n-type layer was formed on the (111) plane, the methane concentration (CH4 / H2), phosphorus concentration (PH3 / CH4), pressure and substrate temperature were set to 0.03-0.05%, 0.002-20%, 100 Torr and 8...

example 2

[0089]Single crystal diamond substrates obtained by high-pressure synthesis and single crystal substrate obtained by vapor phase synthesis, all having the shape of an elongated rectangular parallelepiped, were subjected to sharpening in order to prepare samples having a sharp tip end, as shown in FIG. 12(a)-(d). Diamonds subjected to doping of various types were synthesized on those substrates. The synthesis of diamonds was conducted by a microwave CVD method by using hydrogen gas and methane gas.

[0090]The tip end diameter could be roughly adjusted during polishing, and representative samples with a tip end diameter of about 1 μm and about 10 μm were prepared. The tip end can be also sharpened to a submicron level by diamond re-growth or vertical etching using plasma or ions.

[0091]The conditions of forming a n-type layer on the (111) plane, forming a n-type layer on the (100) surface, and forming a p-type film were identical to those of Example 1.

[0092]All the substrates were boron-...

example 3

[0101]As shown in FIG. 14(a), (b), samples were prepared in which the tip end of the samples had been sharpened in the same manner as in Example 1. The difference between this example and Example 1 was that an i-type layer that was not doped with impurities was formed prior to the formation of the n-type layer. In all other aspects, the structures were identical, and the tests were carried out under the same doping conditions.

[0102]With this method chips having with a tip end in the form of an n-type layer and a pin stack were fabricated.

[0103]Similarly to Example 1, a sample in which a boron-doped p-type layer was formed prior to the formation of the i-type layer was also prepared. Although similar structures of a pin-stack type were obtained, the advantage of the latter structure was that the junction surface could use a CVD film in which the impurities of the p-type layer were accurately controlled. Another feature identical to that of Example 1 was that the produced samples in w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com