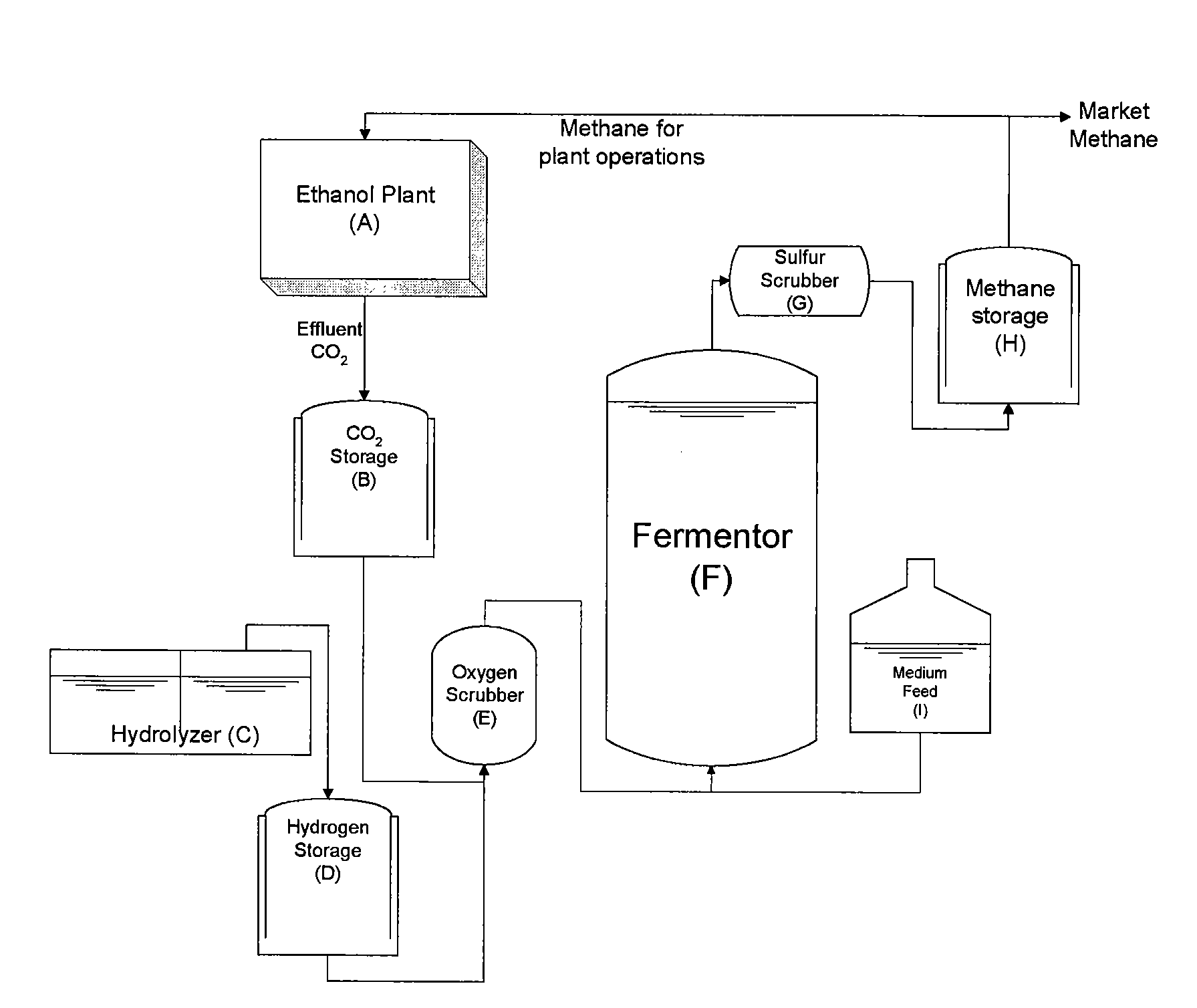

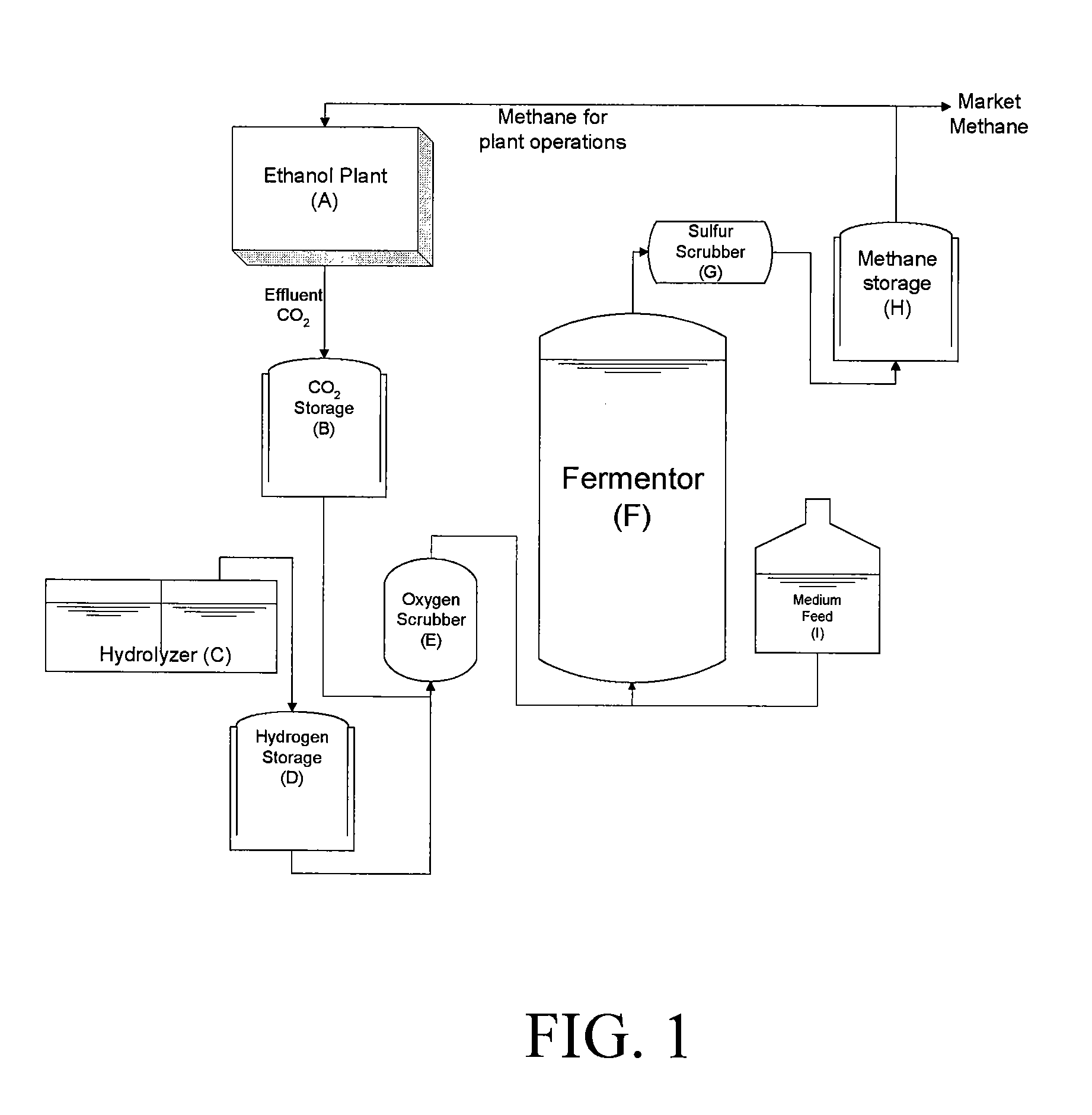

System for the production of methane from co2

a methane and co2 technology, applied in the field of co2 methane production systems, can solve the problems of not being energetically or economically competitive with ethanol produced abroad, and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

General Setup for Bench Scale Bioreactor

[0047]A bench-scale bioreactor was used to test a series of variables important in the design and operation of an industrial scale bioreactor. A 1.3 L fermenter vessel (bioreactor) (BioFlo 110, New Brunswick), fitted with an Ingold autoclavable pH electrode for measuring pH in the medium and a Lazar Labs double junction platinum band autoclavable ORP electrode for measuring the oxidation-reduction potential (ORP) of the medium was used in the following experiments. The bioreactor contained 1 L culture medium and was stirred at 400 rpm with a Rushton impeller. With 1 L of medium, the bioreactor has a headspace of 300 cc of gas. The chamber was also fitted with a peristaltic pump that could control the addition of a chemical reductant, such as Na2S. A second peristaltic pump controlled the constant addition of fresh culture medium to the vessel to enable continuous culture operation. A third peristaltic pump was used to remove excess liquid from...

example 2

Bench Scale Bioreactor Using Methanococcus maripaludis

[0048]The general setup of Example 1 was used with the organism Methanococcus maripaludis. Methanococcus maripaludis is grown at 37° C. in modified McCas medium containing the following components per L of medium: KCl 0.335 g, MgCl2.6H2O 2.75 g, MgSO4.7H2O 3.45 g, CaCl2.2H2O 0.14 g, NH4Cl 0.5 g, NaHCO3 8.4 g, NaCl 22 g, K2HPO4 0.14 g, FeSO4.7H2O 9.5 mg, Resazurin 1 mg, Casamino acids 2 g, cysteine.H2O.HCl 0.5 g, Na3Citrate.2H2O 21 mg, MnSO4.2H2O 5 mg, CoCl2(0.6H2O) 1 mg, ZnSO4(0.7H2O) 1 mg, CuSO4.5H2O 0.1 mg, AlK(SO4)2 0.1 mg, H3BO4 0.1 mg, Na2MoO4.2H2O 1 mg, NiCl2.6H2O 0.25 mg, Na2SeO3 2 mg, V(III)Cl 0.1 mg, Na2WO4.2H2O 1 mg, biotin 0.02 mg, folic acid 0.02 mg, pyridoxine HCl 0.10 mg, thiamine HCl 0.05 mg, riboflavin 0.05 mg, nicotinic acid 0.05 mg, DL-calcium pantothenate 0.05 mg, vitamin B12 0.001 mg, p-aminobenzoic acid 0.05 mg, lipoic acid 0.05 mg. After autoclaving and before inoculation, the medium was reduced by the addi...

example 3

Effect of Agitation on Methane Production of Methanococcus maripaludis

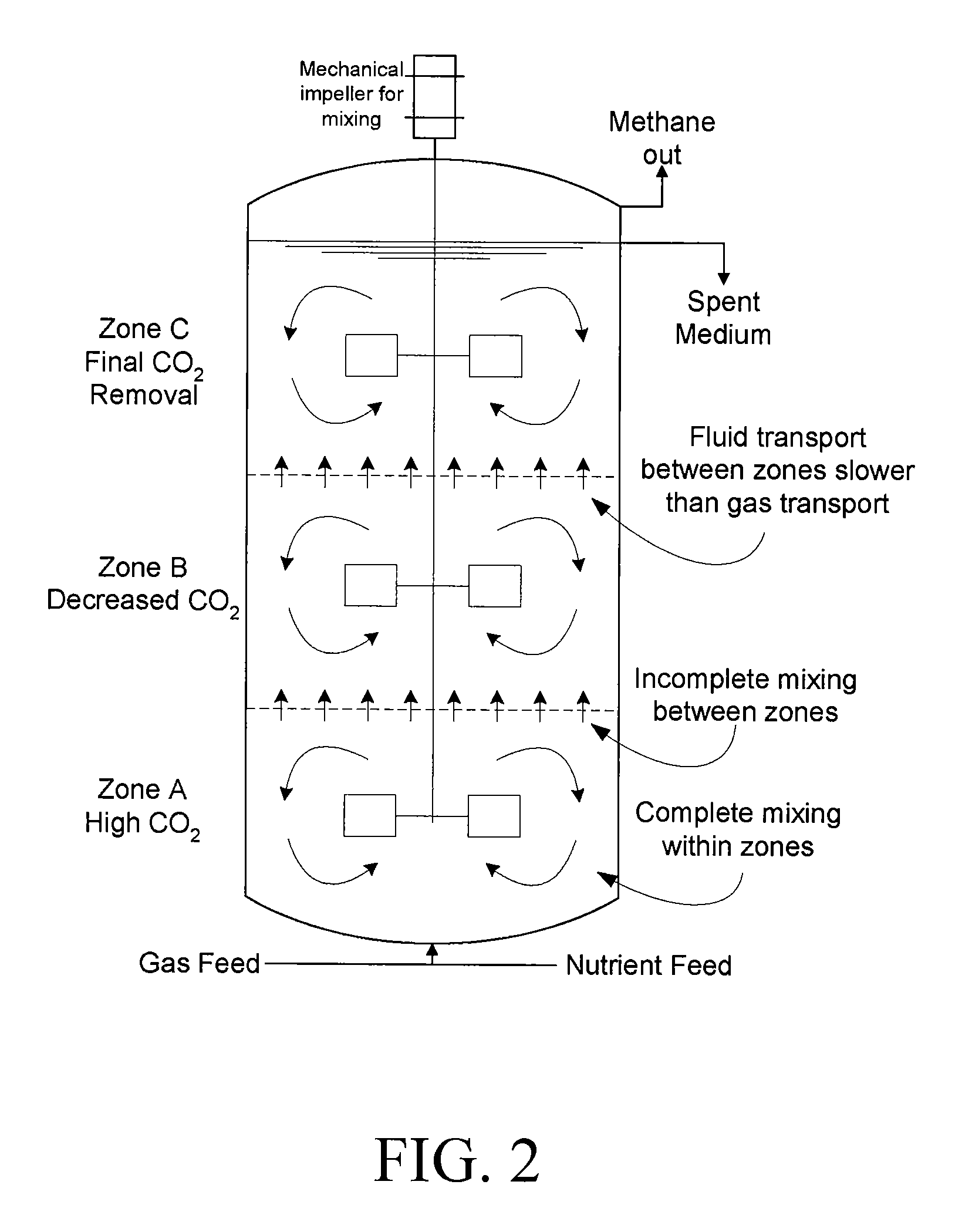

[0050]The turbidity of the culture obtained in Example 2 continued to increase after the gas-to-liquid mass transfer-limited rate of methane production was reached, providing an excess of biological catalytic capacity. This additional catalytic capacity can be accessed by changing physical parameters that increase the gas-to-liquid mass transfer rate. As shown in FIG. 5, the mixing rate in the culture was varied from the standard 400 rpm. A total feed rate of a 4:1 H2:CO2 gas mixture (250 cc / min (288 vvd H2; 72 vvd CO2)) was used. At this gas feed rate, the conversion efficiency of both CO2 and hydrogen reaches 55-56% at higher mixing speeds demonstrating that higher stirring rates increases the gas-to-liquid mass transfer and therefore higher methane production. Other abiotic methods that may be used to increase the gas-to-liquid mass transfer and hence the methane production rate include 1) increased gas pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com