Solar cell

a solar cell and film technology, applied in the field of thin film solar cells, can solve the problems of glass substrates that cannot be easily damaged, so as to achieve low cost, low cost, and high peeling resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

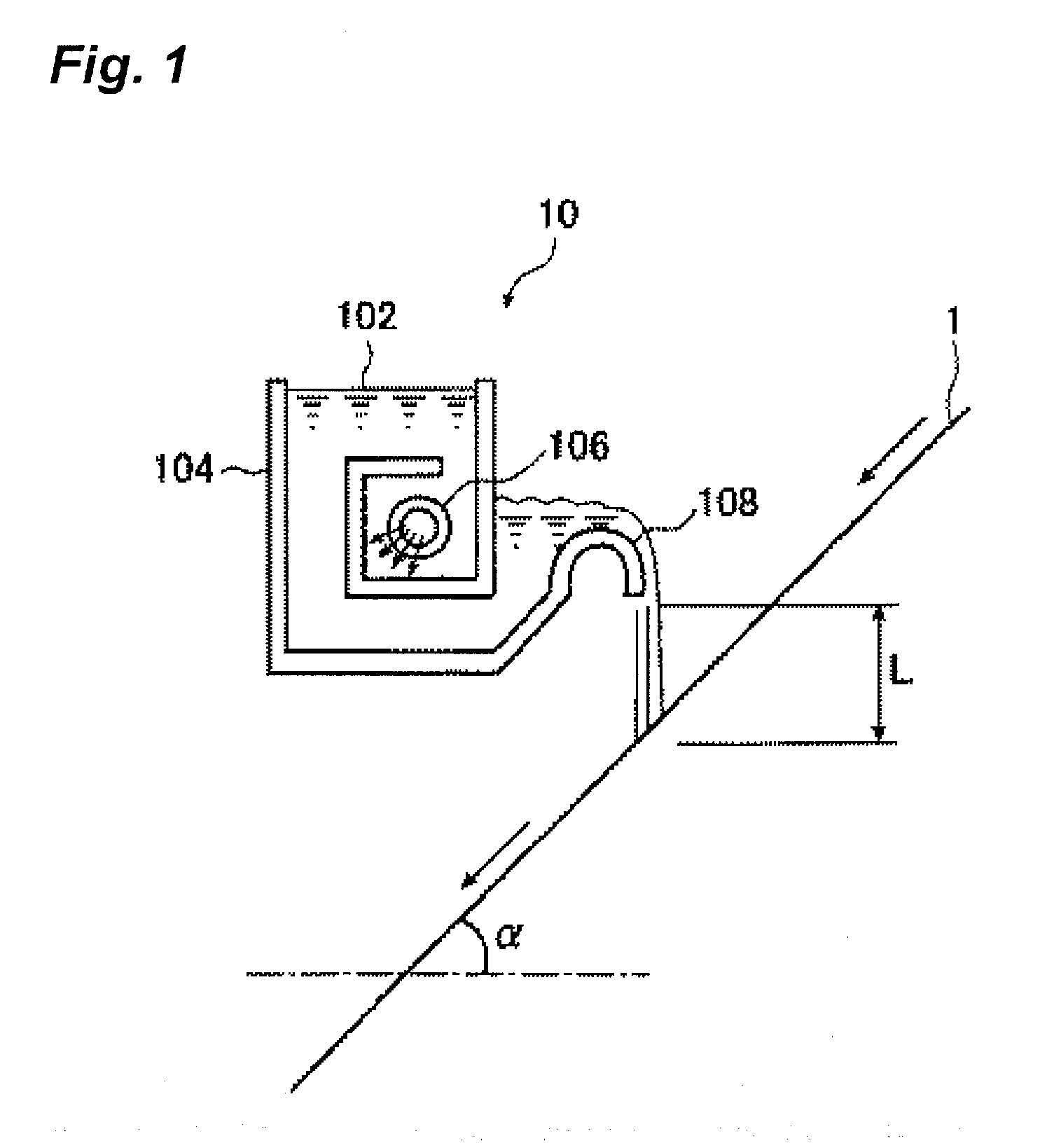

[0389]The surface of the mechanically-polished, rolled aluminum sheet with a thickness of 0.24 mm was grained with a rotary nylon brush (6-10 nylon) and an aqueous suspension of 20% by weight of 400 mesh Pumice Stone (trade name, manufactured by Kyoritsu Ceramics Materials Co., Ltd.) and then thoroughly washed with water. The aluminum sheet was immersed in an aqueous 10% by weight sodium hydroxide solution (containing 5% by weight of aluminum) and so etched that aluminum was dissolved in an amount of 5 g / m2. Thereafter, the aluminum sheet was washed with running water, further neutralized with 20% by weight nitric acid, and then washed with water.

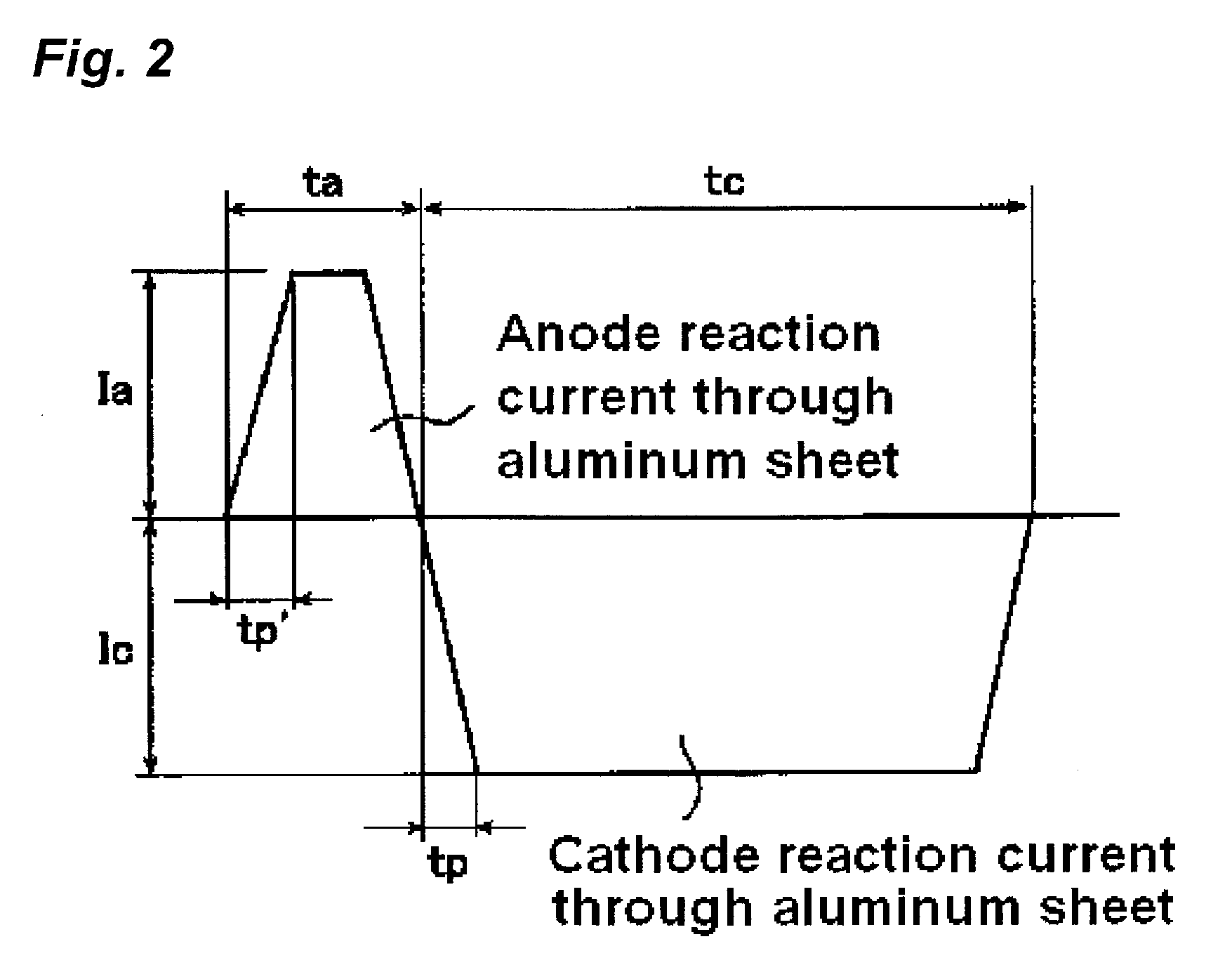

[0390]The aluminum sheet was then subjected to a surface roughening treatment with an anodic electric quantity of 160 Coulomb / dm2 in an aqueous 1% by weight nitric acid solution (containing 0.5% of aluminum) using a rectangular alternating waveform voltage with an anodic voltage of 10.5 V and a cathodic voltage of 9.3 V (current ratio r=0.9...

example 2

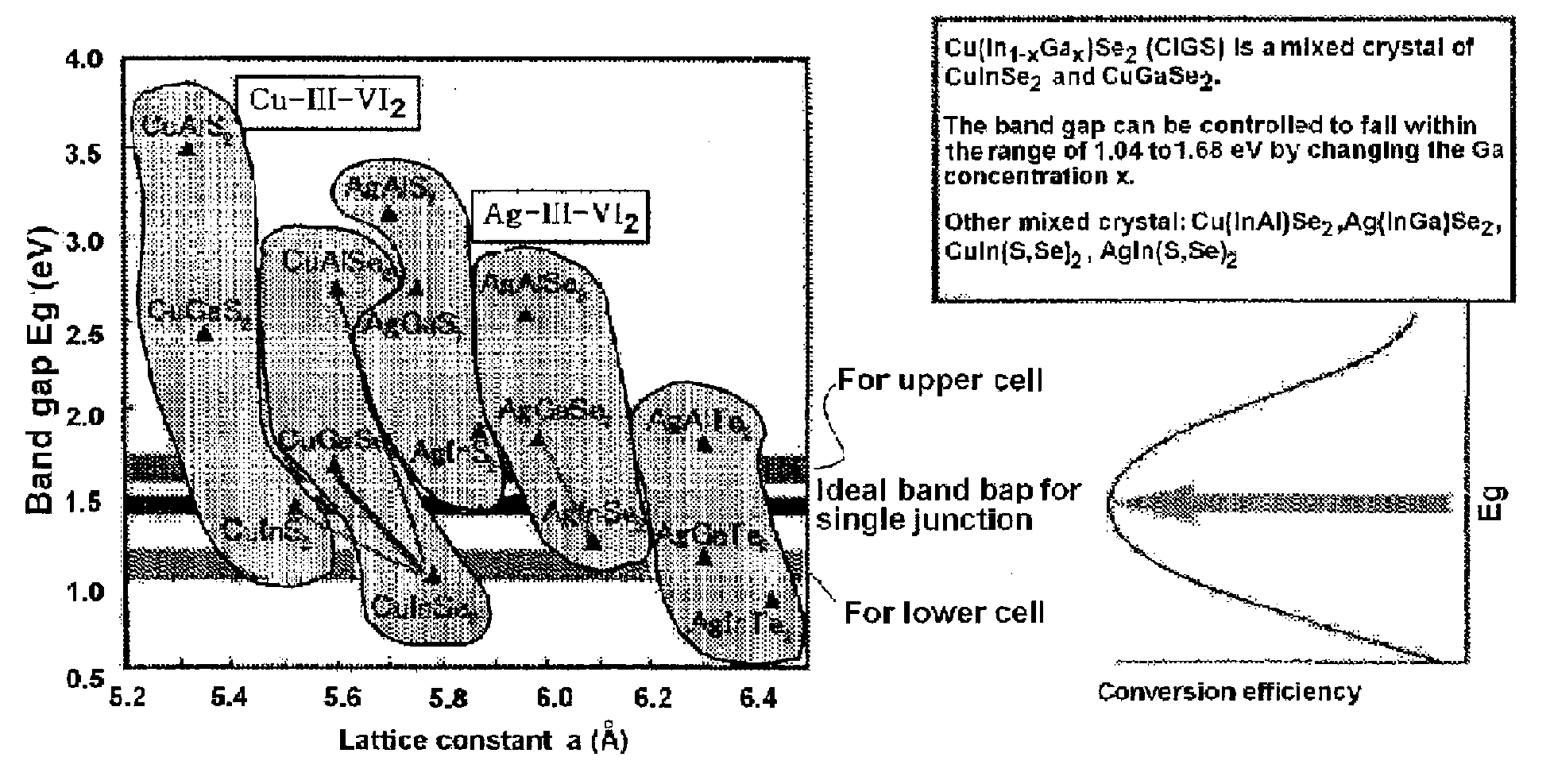

[0400]The sample of Example 1 according to the invention was used as a substrate. After a Mo layer was formed on the anodized aluminum substrate by RF sputtering (high frequency sputtering), a NaF layer was formed thereon by RF sputtering, and a Mo layer was further formed thereon by RF sputtering. The resulting Mo / NaF / Mo multilayer film had a thickness of about 1.0 μm. A CuInGaSe2 thin film was deposited on the Mo film in a vacuum chamber. In the deposition of the CuInGaSe2 thin film, a Cu (the primary component of CuInGaSe2) evaporation source, an In evaporation source, a Ga evaporation source, and a Se evaporation source were provided in the vacuum chamber 1, and the Cu, In, Ga, Se evaporation source crucibles were heated at the degree of vacuum of about 10−7 Torr so that each element was evaporated. In this process, the crucible temperature was controlled as needed. The CuInGaSe2 thin film was formed to have a two-layer structure as described below. The first layer of the two-la...

example 3

[0405]The surface of the mechanically-polished, rolled aluminum sheet with a thickness of 0.24 mm was grained with a rotary nylon brush (6-10 nylon) and an aqueous suspension of 20% by weight of 400 mesh Pumice Stone (trade name, manufactured by Kyoritsu Ceramics Materials Co., Ltd.) and then thoroughly washed with water. The aluminum sheet was immersed in an aqueous 10% by weight sodium hydroxide solution (containing 5% by weight of aluminum) and so etched that aluminum was dissolved in an amount of 5 g / m2. Thereafter, the aluminum sheet was washed with running water, further neutralized with 20% by weight nitric acid, and then washed with water.

[0406]The aluminum sheet was then subjected to a surface roughening treatment with an anodic electric quantity of 160 Coulomb / dm2 in an aqueous 1% by weight nitric acid solution (containing 0.5% of aluminum) using a rectangular alternating waveform voltage with an anodic voltage of 10.5 V and a cathodic voltage of 9.3 V (current ratio r=0.9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com