Process for Producing Carbon Nanotubes from Renewable Raw Materials

a technology of carbon nanotubes and raw materials, applied in the direction of specific nanostructure formation, chemistry apparatus and processes, textiles and papermaking, etc., can solve the problems of consuming a great deal of energy, reducing the productivity of workers, and reducing the risk of powder flying off, so as to reduce the risk of granulometry by impact, the effect of limiting the load loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

CNT Synthesis Process

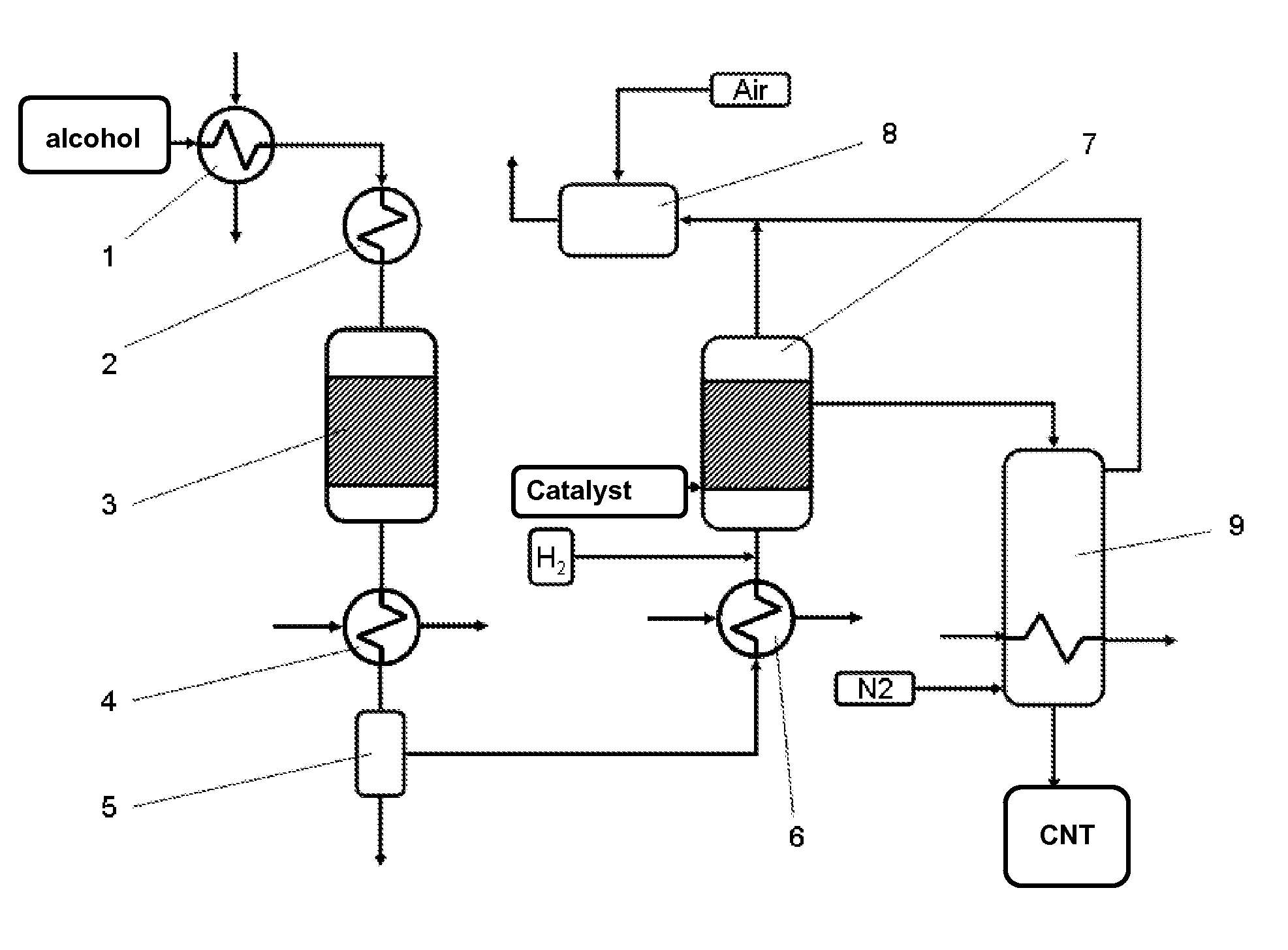

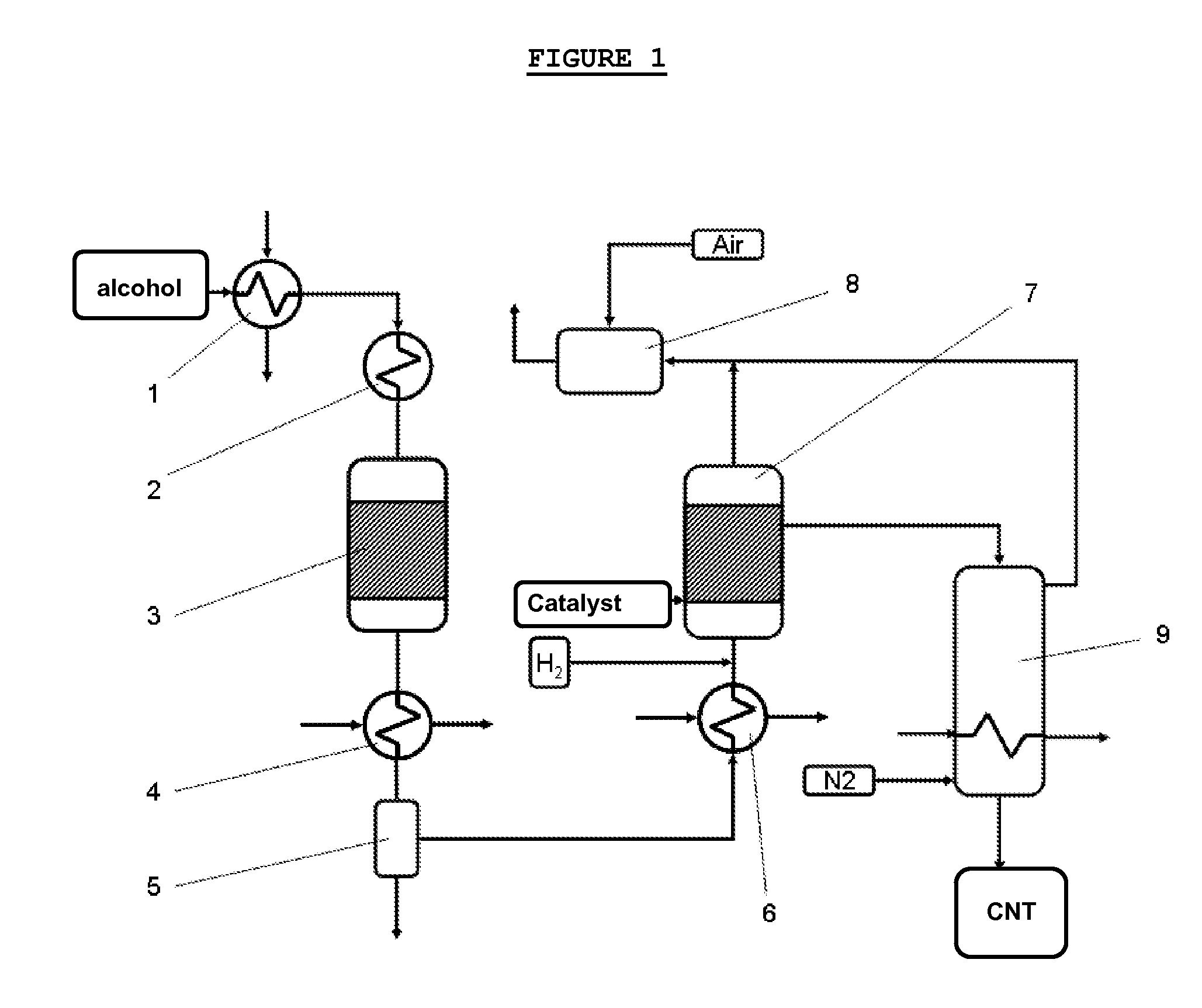

[0060]As illustrated in FIG. 1, the process according to the invention can be implemented in an installation comprising an ethanol dehydration zone, a CTN synthesis zone and a gaseous effluents treatment zone, the whole assembly making it possible to continuously produce CNTs.

[0061]In this installation, 96% ethanol is vaporized in a vaporizor 1, then preheated in a heat exchanger 2, before being injected into the top of a first reactor 3 with a diameter of 127 mm containing a catalytic bed heated to 300-400° C. and constituted by a layer of ESM110® alumina from EUROSUPPORT, representing a volume of 12700 cm3 and a mass of 6500 g, the ratio of the volumetric flow rate of ethanol to the volume of catalyst being 1 h−1. The mixture of water and ethylene produced in the reactor is cooled down in the heat exchanger 4, before being conveyed to a gas-liquid separator 5 where the ethylene and the water (optionally mixed with by-products) are separated.

[0062]The ethylene ...

example 2

CTN Synthesis Process Comprising an in situ Grinding Stage

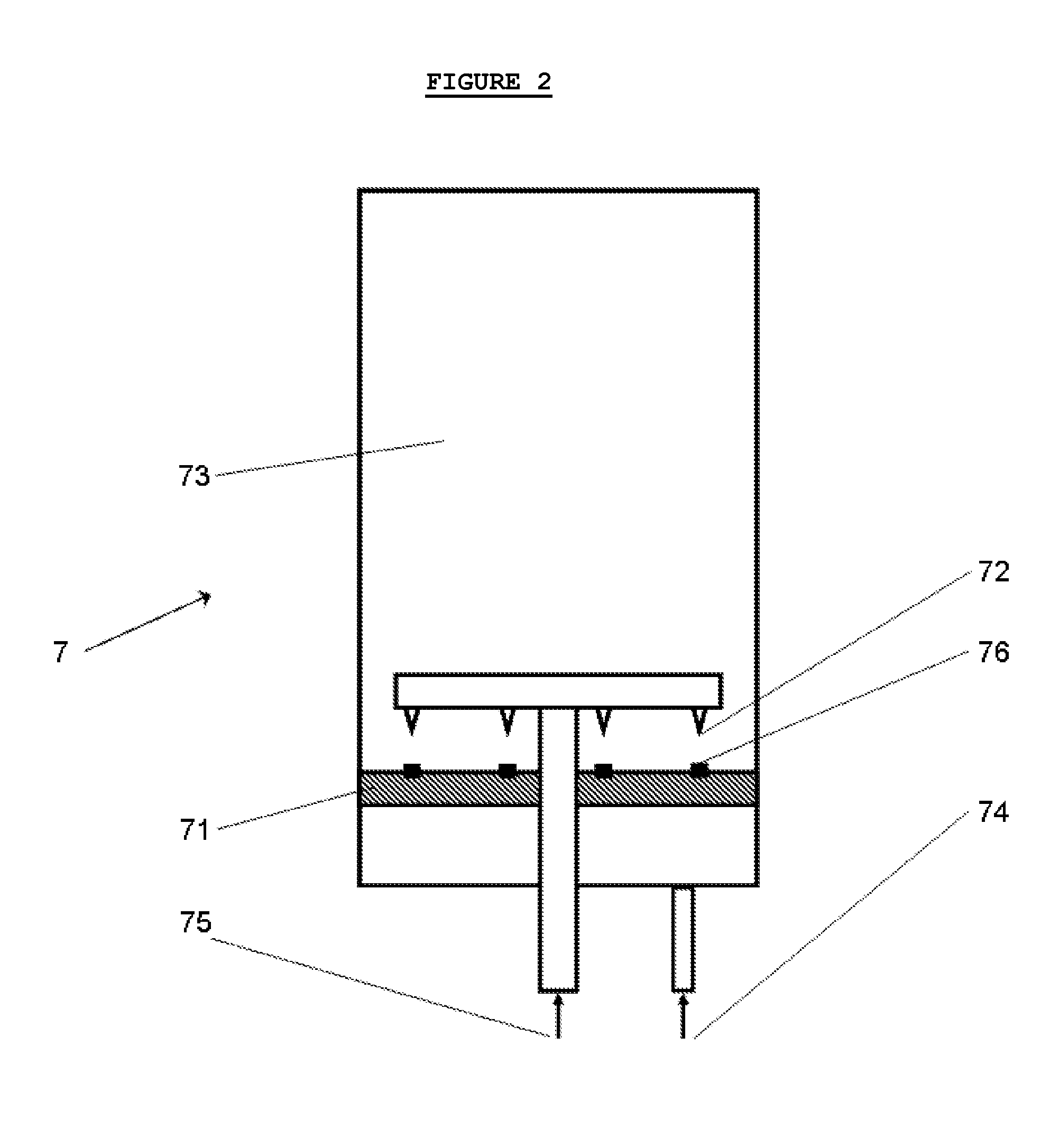

[0069]The process described in Example 1 is repeated, except that gas-jet grinding of the CNTs is carried out in their synthesis reactor.

[0070]The grinding is carried out at the synthesis temperature in a CTN synthesis reactor 7 according to FIG. 2 provided with a porous distributor 71 equipped with a manifold of nozzles 72 allowing the high-speed injection of gas 75 impacting the CNT powder on the complete targets 76 fixed on the distributor. The medium is fluidized by means of this stream of gas 75, as well as a complementary stream of gas (preferably comprising the reactive gases) 74 passing through the distributor 71.

[0071]The flow rate of the different gas flows and the duration of injection into the nozzles are regulated so that the medium remains fluidized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com