Electroplating apparatus and method

a technology of electroplating apparatus and substrate, which is applied in the direction of electrolysis process, electrical apparatus, electrolysis components, etc., can solve the problems of insufficient development of appropriate etching solution for etching copper film in order to form the gate electrode and the gate line, delay and distortion of the gate signal and data signal, etc., to minimize the processing time and minimize the alignment error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

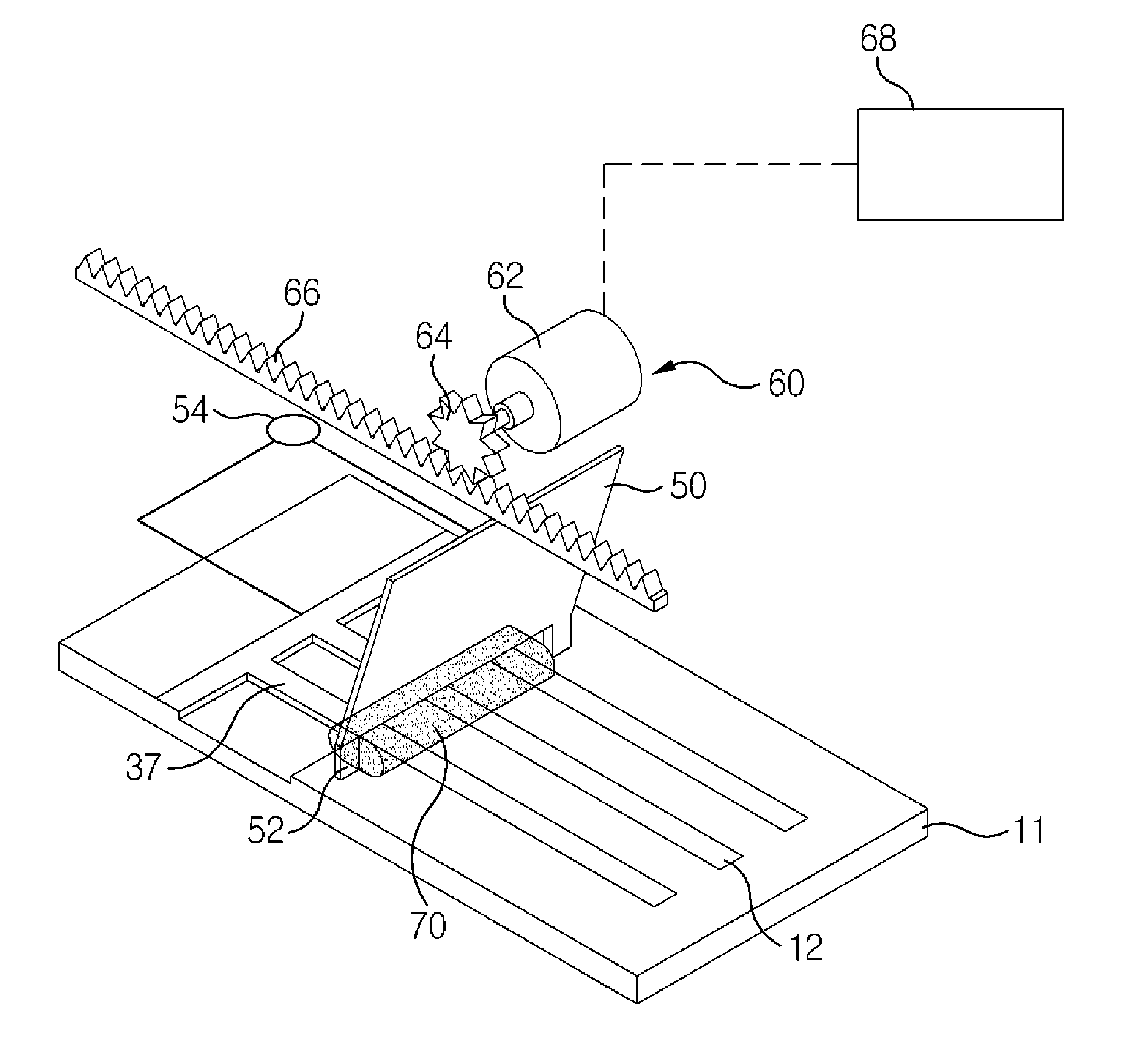

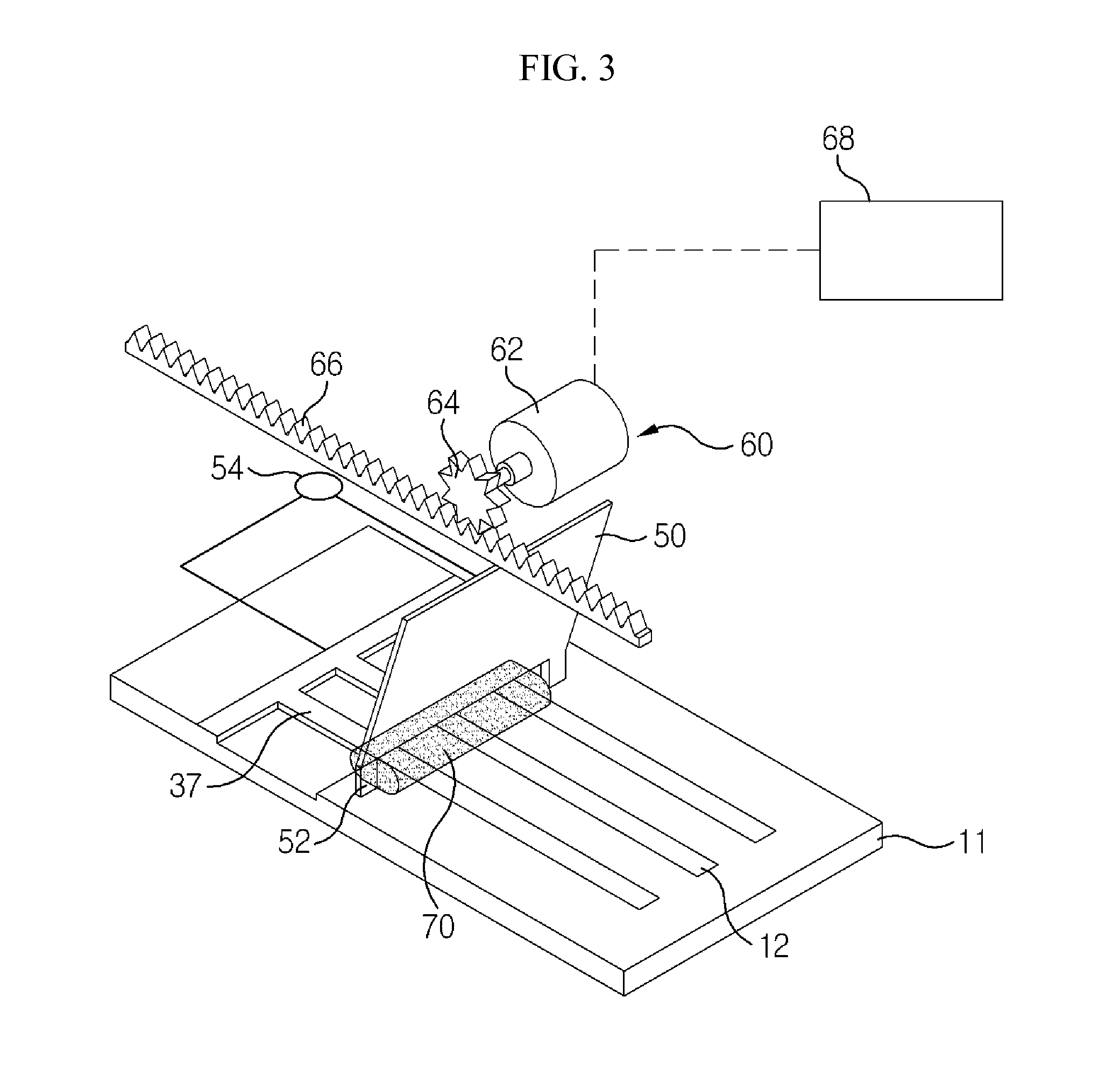

[0081]FIG. 3 is a perspective view showing an electroplating apparatus according to the present invention.

[0082]Referring to FIG. 3, the electroplating apparatus according to the first embodiment according to the present invention includes: a copper electrode plate 50 that is disposed so as to move along a rectilinear line on an upper surface of an insulating substrate 11 on which seed electrodes 12 are formed; a driving unit 60 that makes the copper electrode plate 50 move reciprocally along a rectilinear line; and a power supply 54 that applies electric current between the copper electrode plate 50 and each of the seed electrodes 12.

[0083]A method of forming the seed electrodes 12 on the insulating substrate 11 will follow in detail.

[0084]In the case that the insulating substrate 11 is formed of a hydrophobic material, an electrolyte 70 does not spread but forms on the surface of the insulating substrate 11. As a result, the electrolyte 70 stay between the copper electrode plate 5...

second embodiment

[0102]FIG. 4 is a perspective view showing an electroplating apparatus according to the present invention.

[0103]Referring to FIG. 4, the electroplating apparatus according to the second embodiment of the present invention includes: a copper electrode plate 50 that is disposed so as to move along a rectilinear line on an upper surface of an insulating substrate 11 on which seed electrodes 12 are formed; a pushing plate 56 that is disposed at the rear side of the copper electrode plate 50 to thus push an electrolyte 70 that is placed at the rear side of the copper electrode plate 50 toward the copper electrode plate 50; a driving unit 60 that makes the copper electrode plate 50 and the pushing plate 56 move along a rectilinear line; and a power supply 54 that is connected between the copper electrode plate 50 and each of the seed electrodes 12 and thus applies electric current between the copper electrode plate 50 and each of the seed electrodes 12.

[0104]If the insulating substrate 11...

third embodiment

[0111]FIG. 5 is a perspective view showing an electroplating apparatus according to the present invention.

[0112]Referring to FIG. 5, the electroplating apparatus according to the third embodiment of the present invention includes: a copper electrode plate 50 that is disposed so as to move along a rectilinear line on an upper surface of an insulating substrate 11 on which seed electrodes 12 are formed; an electrolyte supplier 80 that is disposed at the front side of the copper electrode plate 50 to thus supply an electrolyte 70 on the surface of the insulating substrate 11; an electrolyte remover 90 that is disposed at the rear side of the copper electrode plate 50 to thus remove the electrolyte from the copper electrode plate 50; a driving unit 60 that makes the copper electrode plate 50, the electrolyte supplier 80 and the electrolyte remover 90 move along a rectilinear line; and a power supply that is connected between the copper electrode plate 50 and each of the seed electrodes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| total length | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

| thick | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com