One-dimensional titanium nanostructure and method for fabricating the same

a titanium nanostructure and one-dimensional technology, applied in the direction of crystal growth process, polycrystalline material growth, transportation and packaging, etc., can solve the problems of high manufacturing cost, high manufacturing cost, and high manufacturing cost, and achieve the effect of reducing fabrication cost and shortening the manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

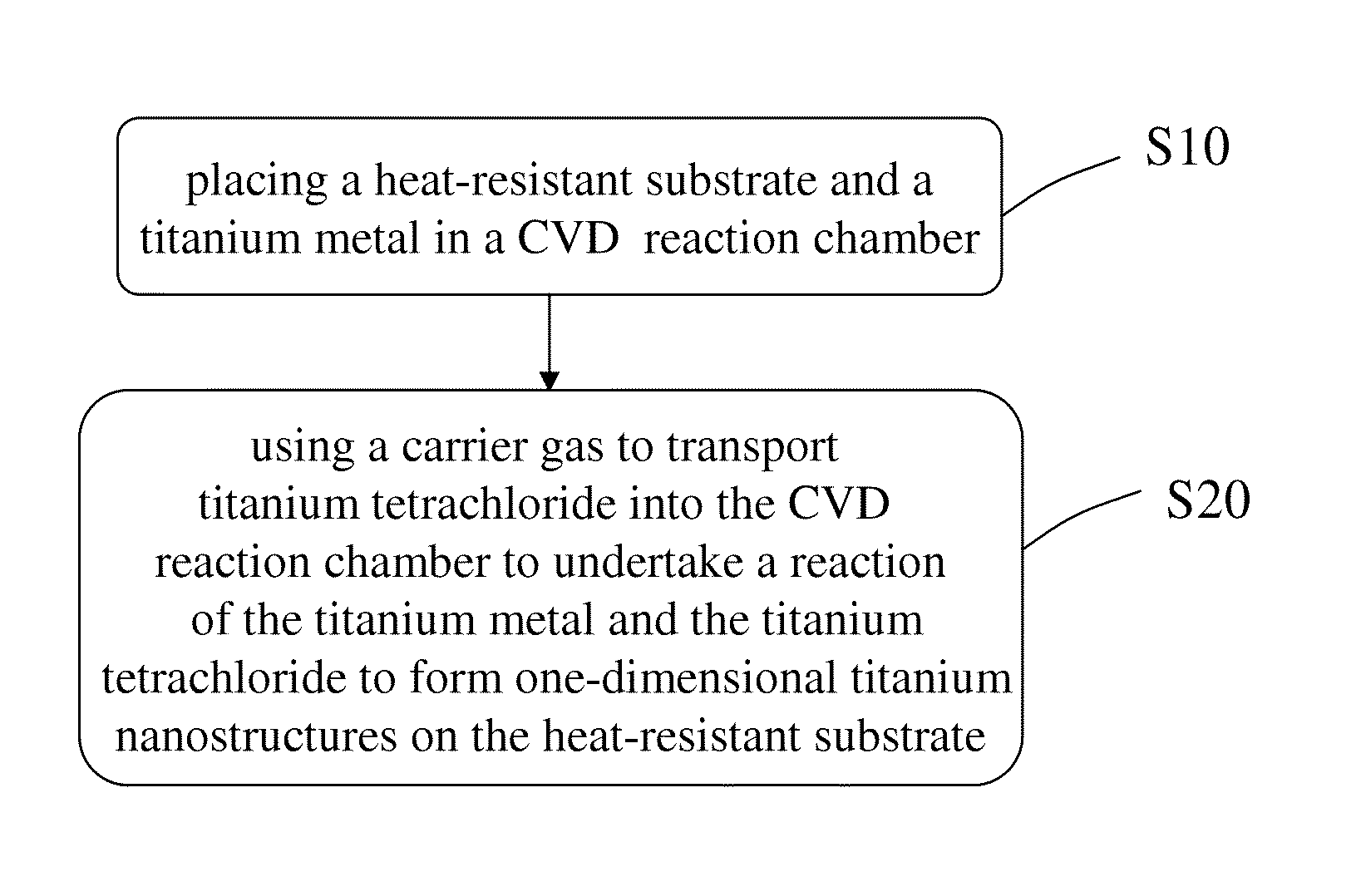

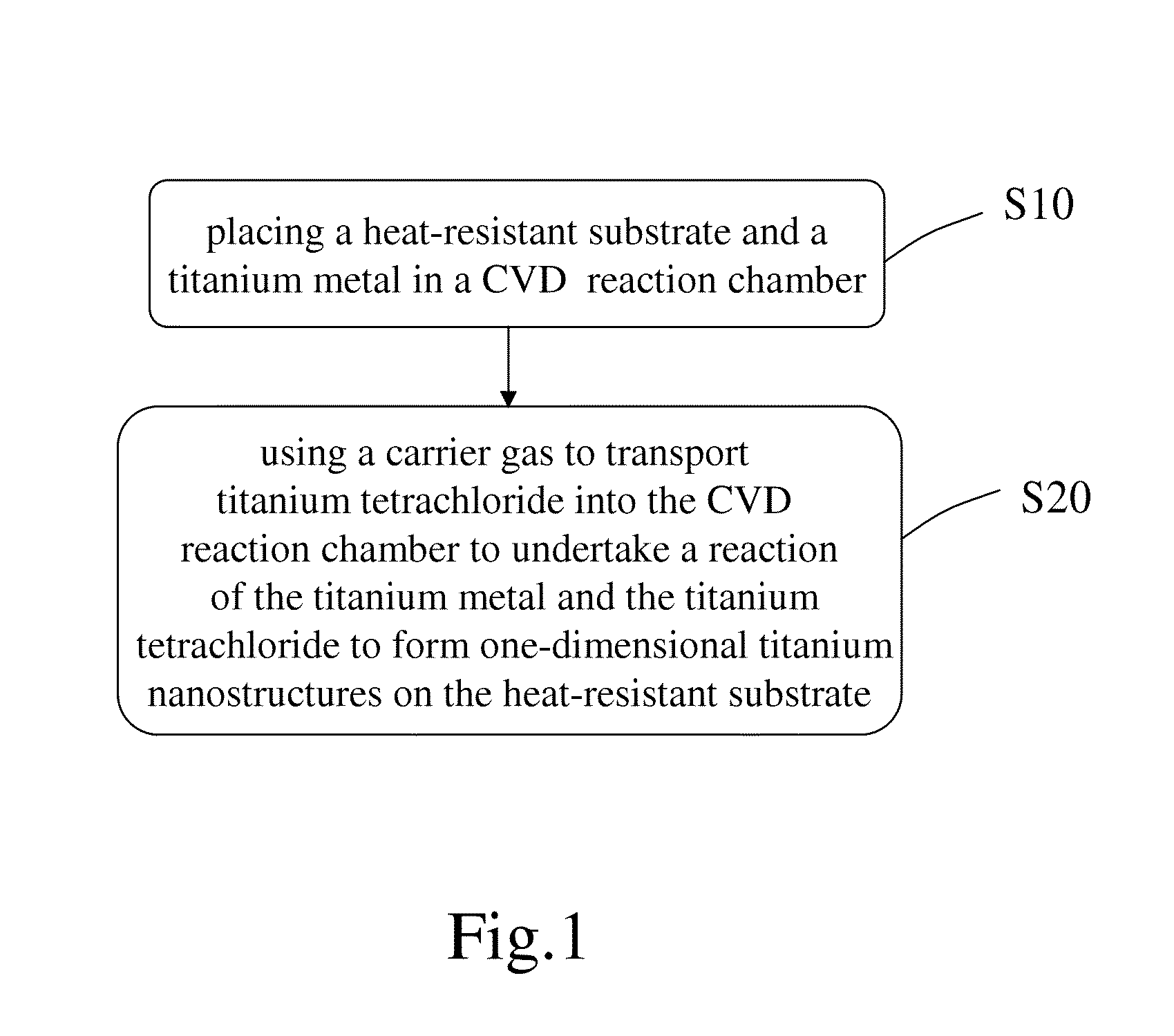

[0026]The present invention provides a method for fabricating a one-dimensional titanium nanostructure, which uses a CVD method to grow a one-dimensional titanium nanostructure. Refer to FIG. 1. The method of the present invention comprises Step S10 and Step S20.

[0027]In Step S10, respectively place a powder of a titanium metal and a heat-resistant substrate in a high temperature region and a low temperature region of a high temperature-resistant quartz tube of a CVD reaction chamber. The heat-resistant substrate may be made of any commercially-available heat-resistant material, such as graphite. The high temperature region and the low temperature region are respectively the region where the titanium metal reacts with titanium tetrachloride and the region where the product is generated. The temperature of the high temperature region and the temperature of the low temperature region are respectively referred to as the reaction temperature and the deposition temperature.

[0028]In Step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com