Extended release suspension compositions

a suspension composition and composition technology, applied in the direction of digestive system, metabolism disorder, pharmaceutical non-active ingredients, etc., can solve the problems of inaccurate dosing and/or dose dumping, large compositions, poor patient compliance, etc., to improve patient compliance, facilitate administration, and improve dose flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

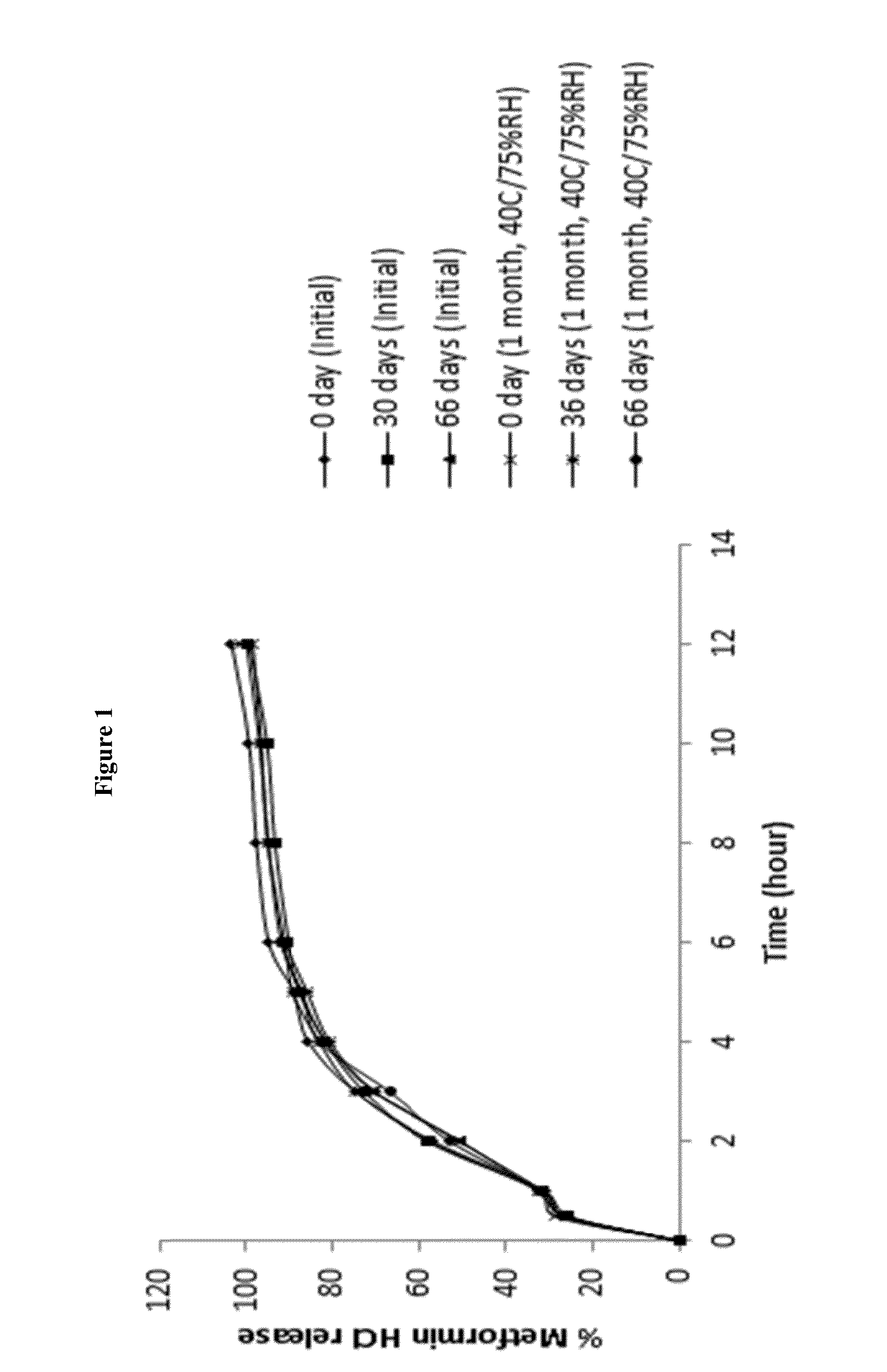

example 1

[0112]

IngredientsQuantity (mg / mL)CoreMetformin hydrochloride100.00Microcrystalline cellulose spheres90.00Hydroxypropylmethyl cellulose5.00Purified waterq.s.Extended Release CoatingEthyl cellulose61.42Dibutyl sebacate6.82Acetoneq.s.Purified waterq.s.Total Weight of Extended Release Beads263.24 mgXylitol450.00Xanthan gum1.500Microcrystalline cellulose - sodium20.00carboxymethyl cellulose (Avicel ® CL 611)Strawberry flavor1.50VehiclePurified waterq.s. to 1 mL

Procedure:

[0113]1. Metformin hydrochloride and hydroxypropylmethyl cellulose were dissolved in purified water.[0114]2. Microcrystalline cellulose spheres were coated with the solution of step 1.[0115]3. Ethyl cellulose and dibutyl sebacate were dispersed in a mixture of acetone and purified water.[0116]4. The beads of step 2 were coated with the coating dispersion of step 3.[0117]5. Xylitol, xanthan gum, microcrystalline cellulose-sodium carboxymethyl cellulose, and strawberry flavor were mixed with the coated beads of step 4.[0118...

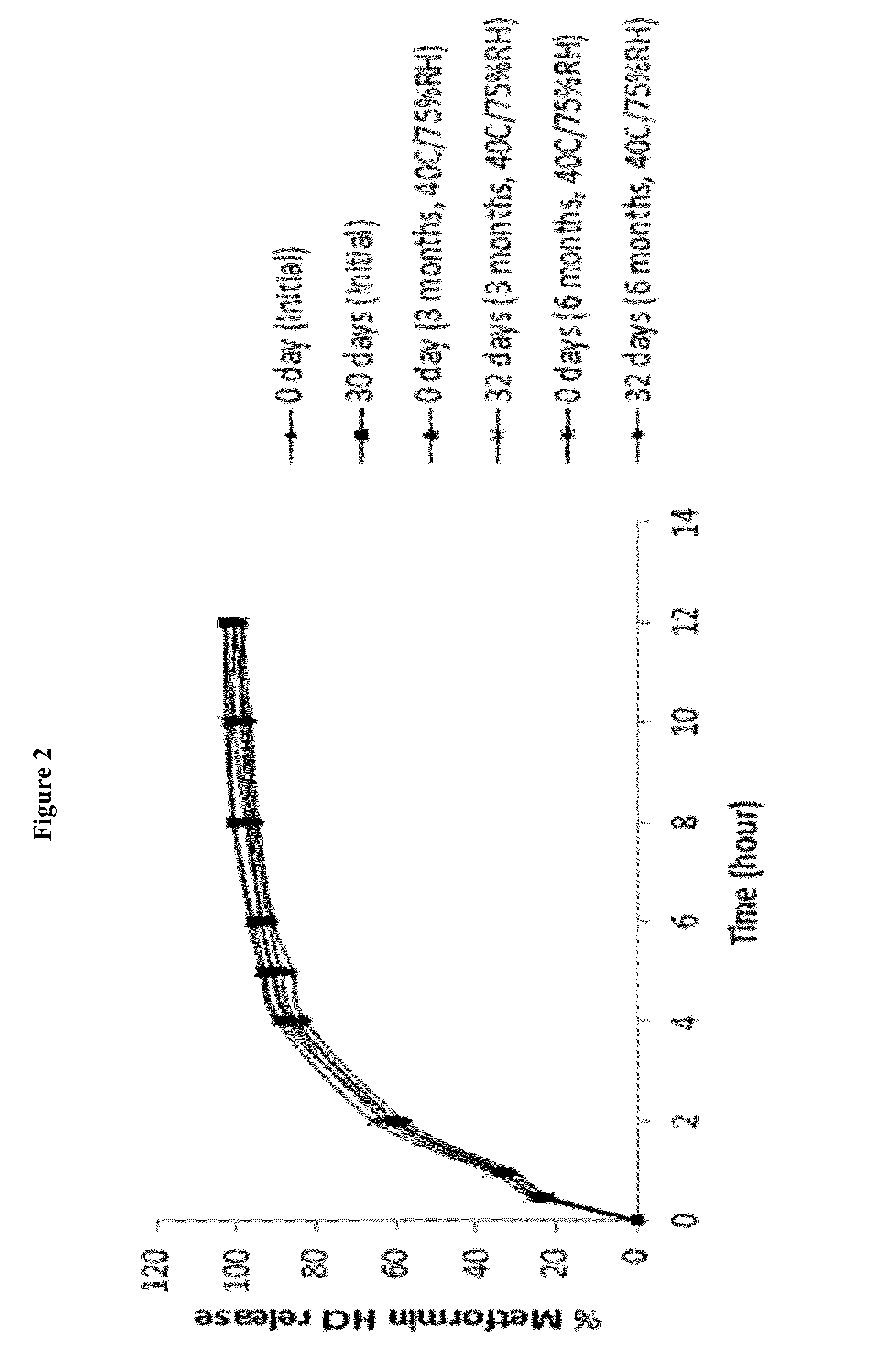

example 2

[0121]

IngredientsQuantity (mg / mL)CoreMetformin hydrochloride100.00Microcrystalline cellulose spheres90.00Hydroxypropylmethyl cellulose5.00Purified waterq.s.Extended Release CoatingEthyl cellulose61.42Dibutyl sebacate6.82Acetoneq.s.Purified waterq.s.Total Weight of Extended Release Beads263.24 mgXylitol450.00Xanthan gum1.50Microcrystalline cellulose - sodium20.00carboxymethyl cellulose (Avicel ® CL 611)Strawberry flavor1.50VehiclePurified waterq.s. to 1 mL

Procedure:

[0122]1. Metformin hydrochloride and hydroxypropylmethyl cellulose were dissolved in purified water.[0123]2. Microcrystalline cellulose spheres were coated with the solution of step 1.[0124]3. Ethyl cellulose and dibutyl sebacate were dispersed in a mixture of acetone and purified water.[0125]4. The beads of step 2 were coated with the coating dispersion of step 3.[0126]5. Xylitol, xanthan gum, microcrystalline cellulose-sodium carboxymethyl cellulose, and strawberry flavor were mixed with the coated beads of step 4 to obt...

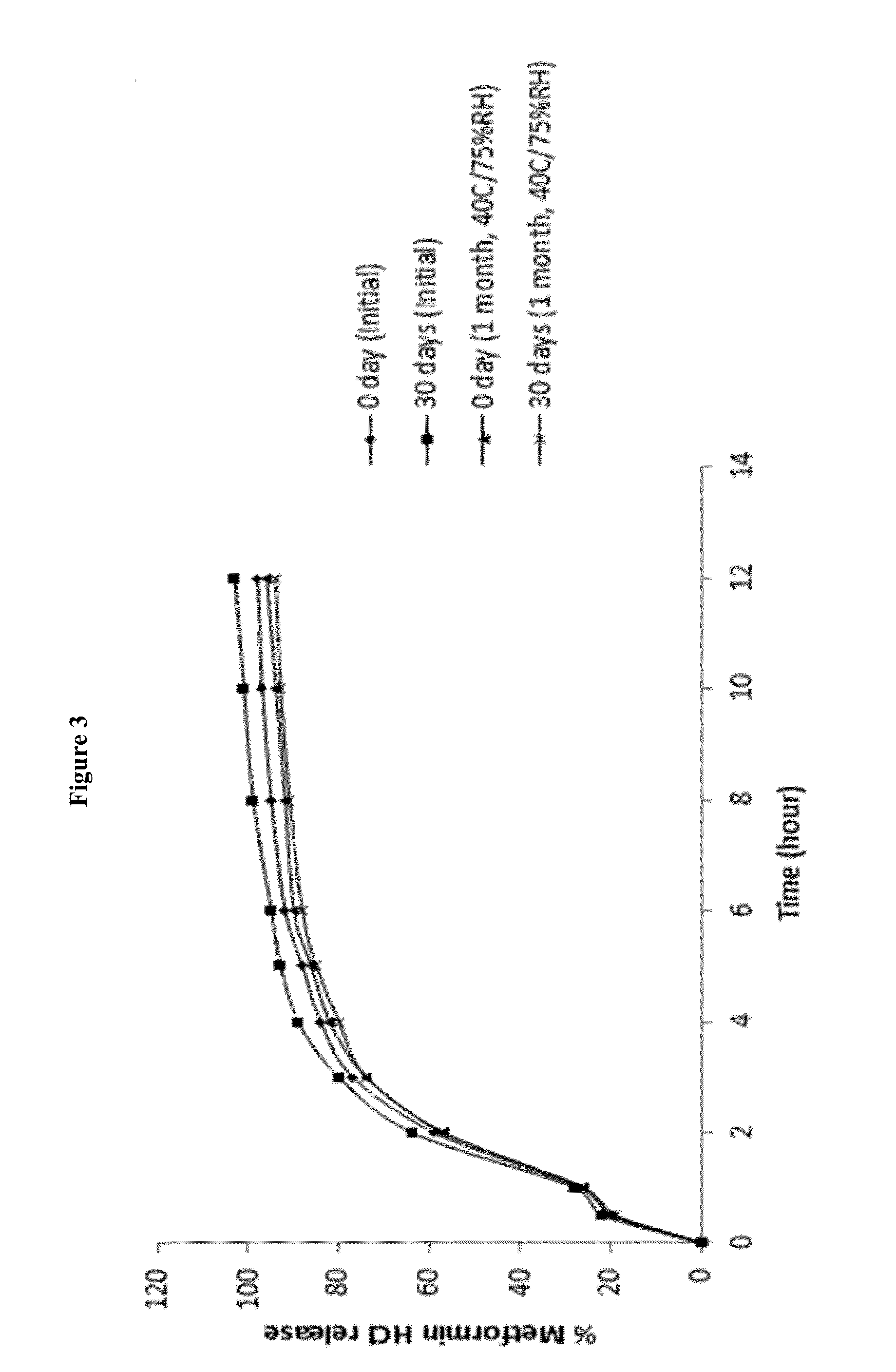

example 3

[0128]

IngredientsQuantity (mg / 5 mL)CoreMetformin hydrochloride500.00Microcrystalline cellulose spheres375.00Hydroxypropylmethyl cellulose25.00Purified waterq.s.Extended Release CoatingEthyl cellulose340.20Dibutyl sebacate37.80Acetoneq.s.Purified waterq.s.Total Weight of Extended Release Beads1278.00 mgXylitol2250.00Xanthan gum7.50Microcrystalline cellulose - sodium100.00carboxymethyl cellulose (Avicel ® RC 591)Strawberry flavor7.50VehiclePurified waterq.s. to 5 mL

Procedure:

[0129]1. Metformin hydrochloride, microcrystalline cellulose, and hydroxypropylmethyl cellulose were sifted and mixed to obtain a blend.[0130]2. The blend of step 1 was mixed with purified water to obtain a wet mass.[0131]3. The wet mass of step 2 was extruded through an extruder.[0132]4. The extrudates of step 3 were spherionized through a spherionizer to obtain beads.[0133]5. The beads of step 4 were dried.[0134]6. Ethyl cellulose and dibutyl sebacate were dispersed in a mixture of acetone and purified water.[01...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Time | aaaaa | aaaaa |

| Electric dipole moment | aaaaa | aaaaa |

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com