Device and method for heating hydrogen storage canister

a technology of hydrogen storage canister and device, which is applied in the direction of catalytic material combustion, furnace, combustion type, etc., can solve the problems of affecting the safety of operation of compressed hydrogen, occupying a large space for compressed hydrogen gas, and high cost of compressed hydrogen compression process, etc., to achieve high efficiency and heat generation speed, the effect of short tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

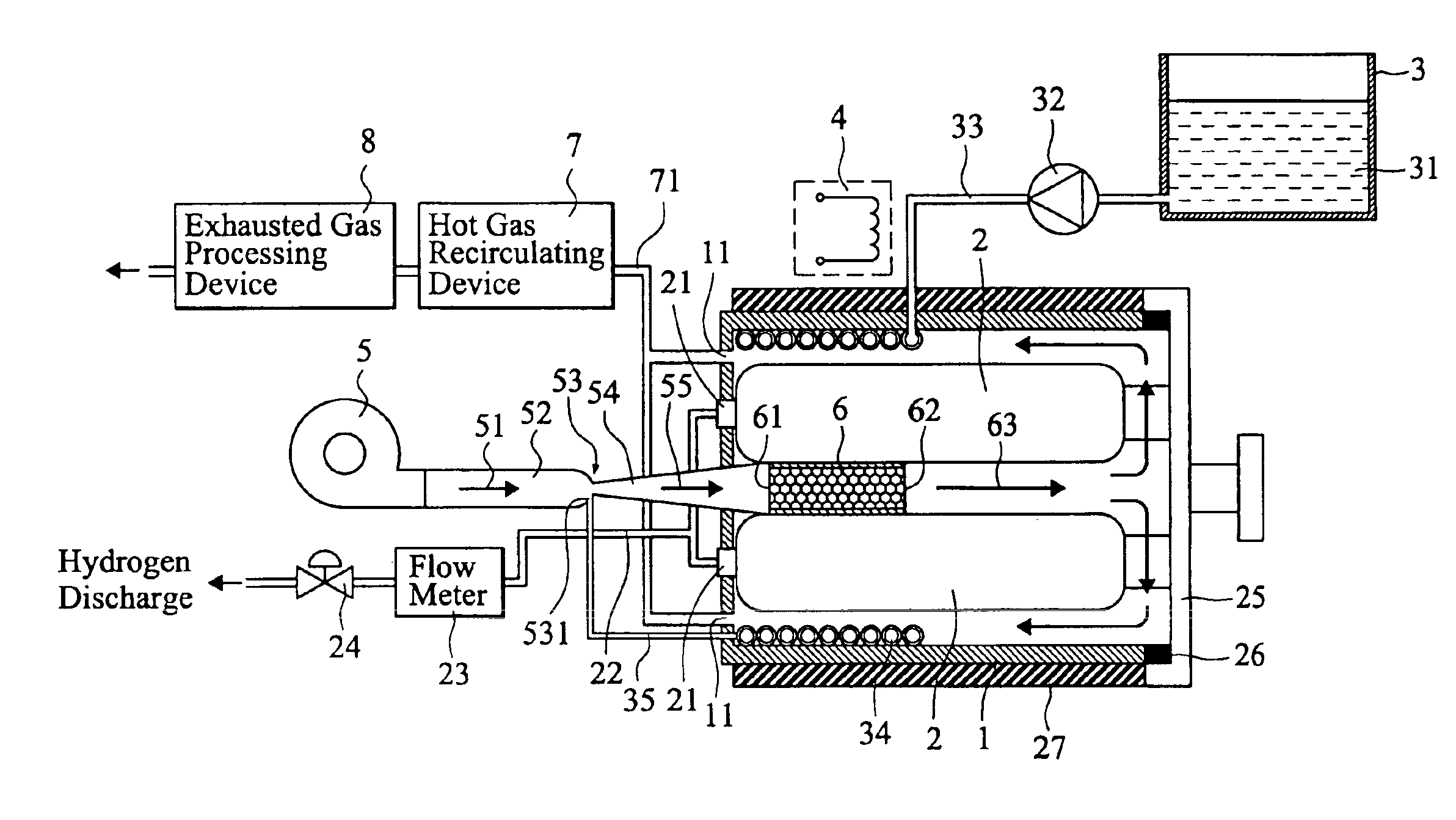

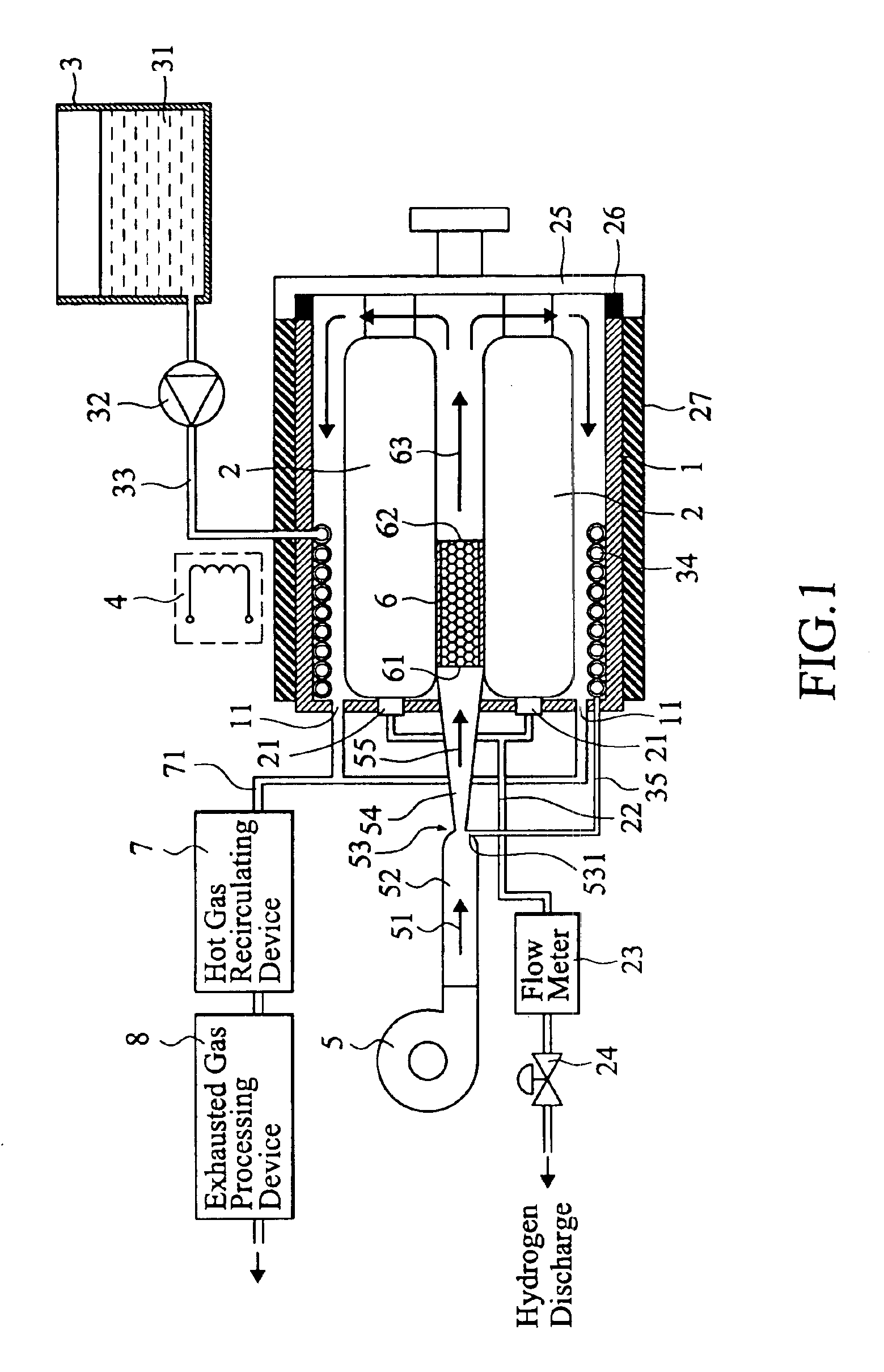

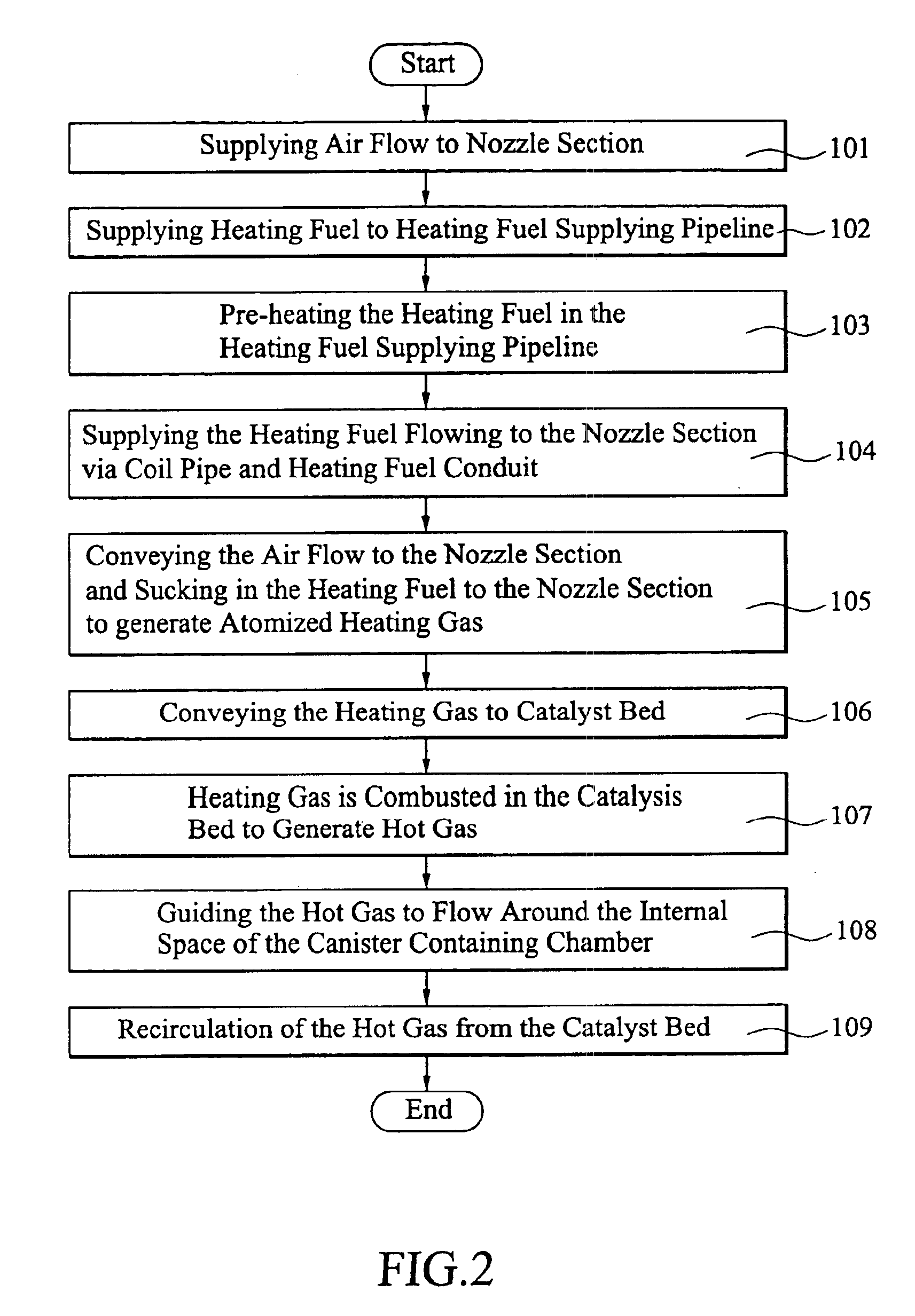

[0018]With reference to the drawings and in particular to FIG. 1, a device for heating hydrogen storage canisters in accordance with a preferred embodiment of the present invention is shown. The heating device comprises a canister containing chamber 1 that is formed with an internal space for accommodation of e.g. two hydrogen storage canisters 2 therein. Each hydrogen storage canister 2 is coupled to one end of a hydrogen supplying pipeline 22 by means of a connecting member 21. The connecting member 21 secures the connection between the hydrogen storage canister 2 and the hydrogen supplying pipeline 22 by means of conventional linkage such as engagement, fastening, screwing or pressing.

[0019]The hydrogen supplying pipeline 22 comprises a flow meter 23 for measuring a flow rate of hydrogen flowing from the hydrogen storage canisters 2, and a pressure regulating valve 24 for regulating the pressure of hydrogen released from the hydrogen supplying pipeline 22.

[0020]The other end of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com