Method and apparatus for altering material

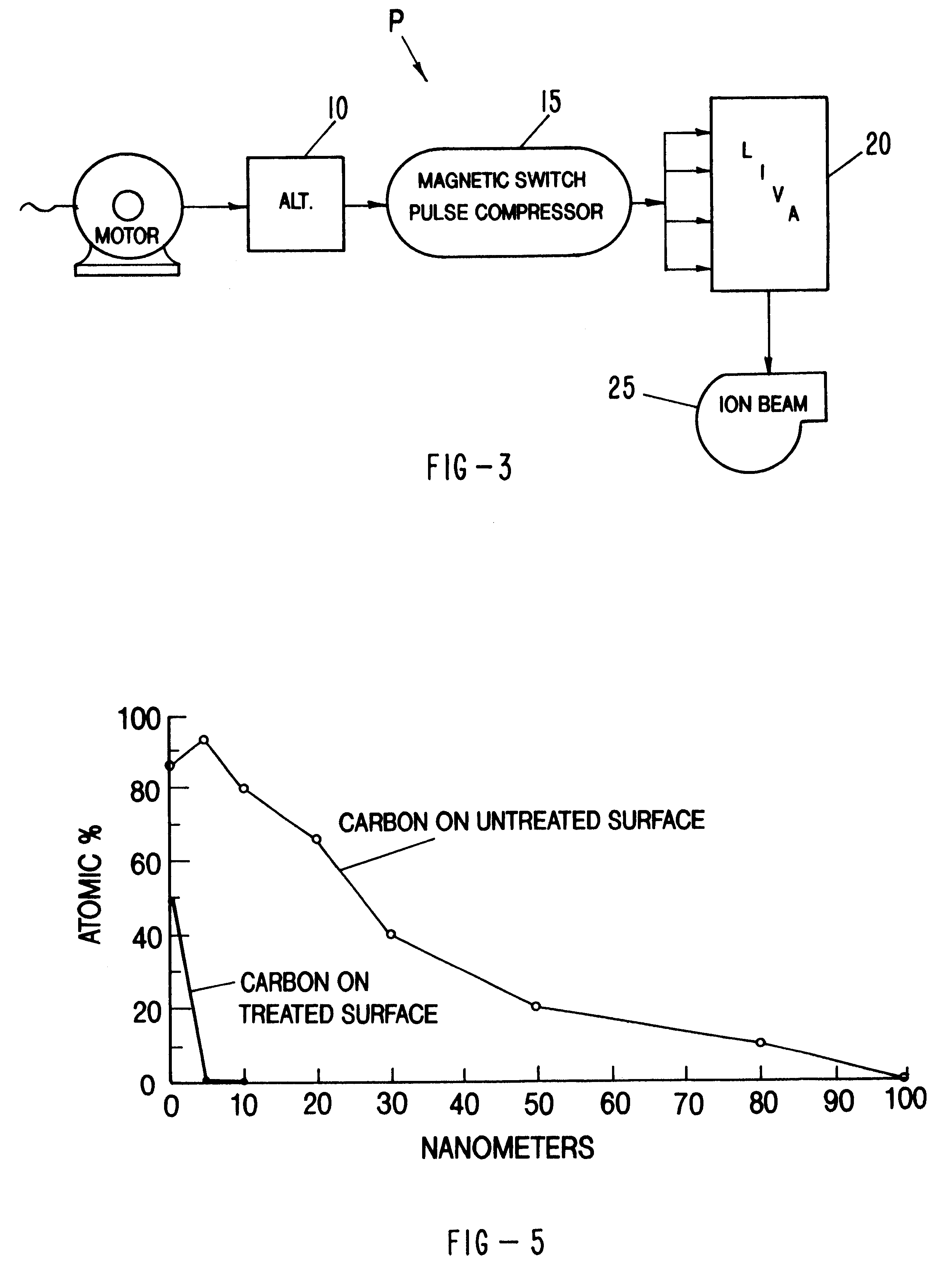

a technology of material and applied in the field of methods and apparatus for altering materials, can solve the problems of unsatisfactory expectations of such technologies, limited commercial success of laser thermally altering the near surface characteristics of materials, and inconvenient treatment, etc., to achieve high average power and repetitive operation, high energy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

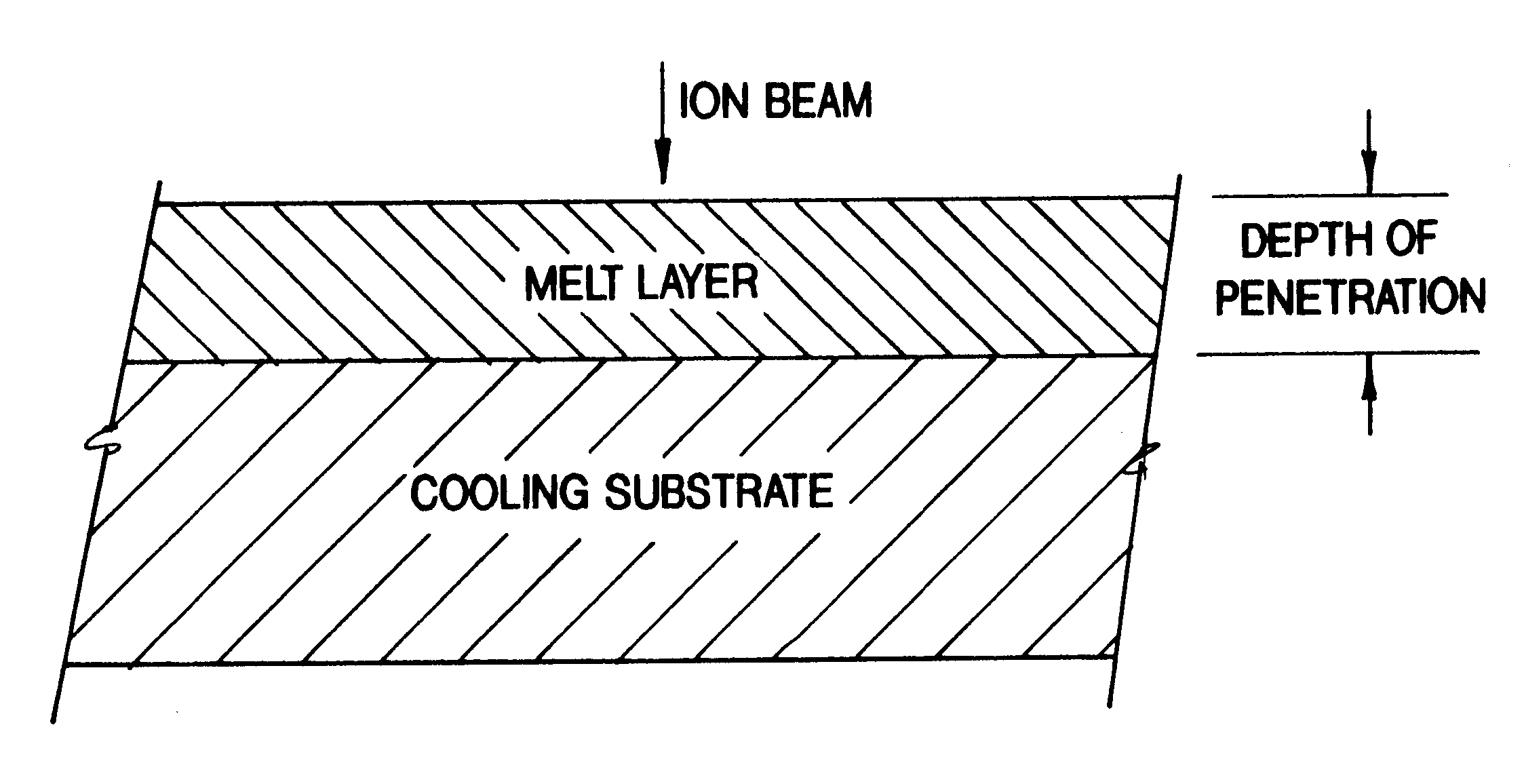

Method used

Image

Examples

examples

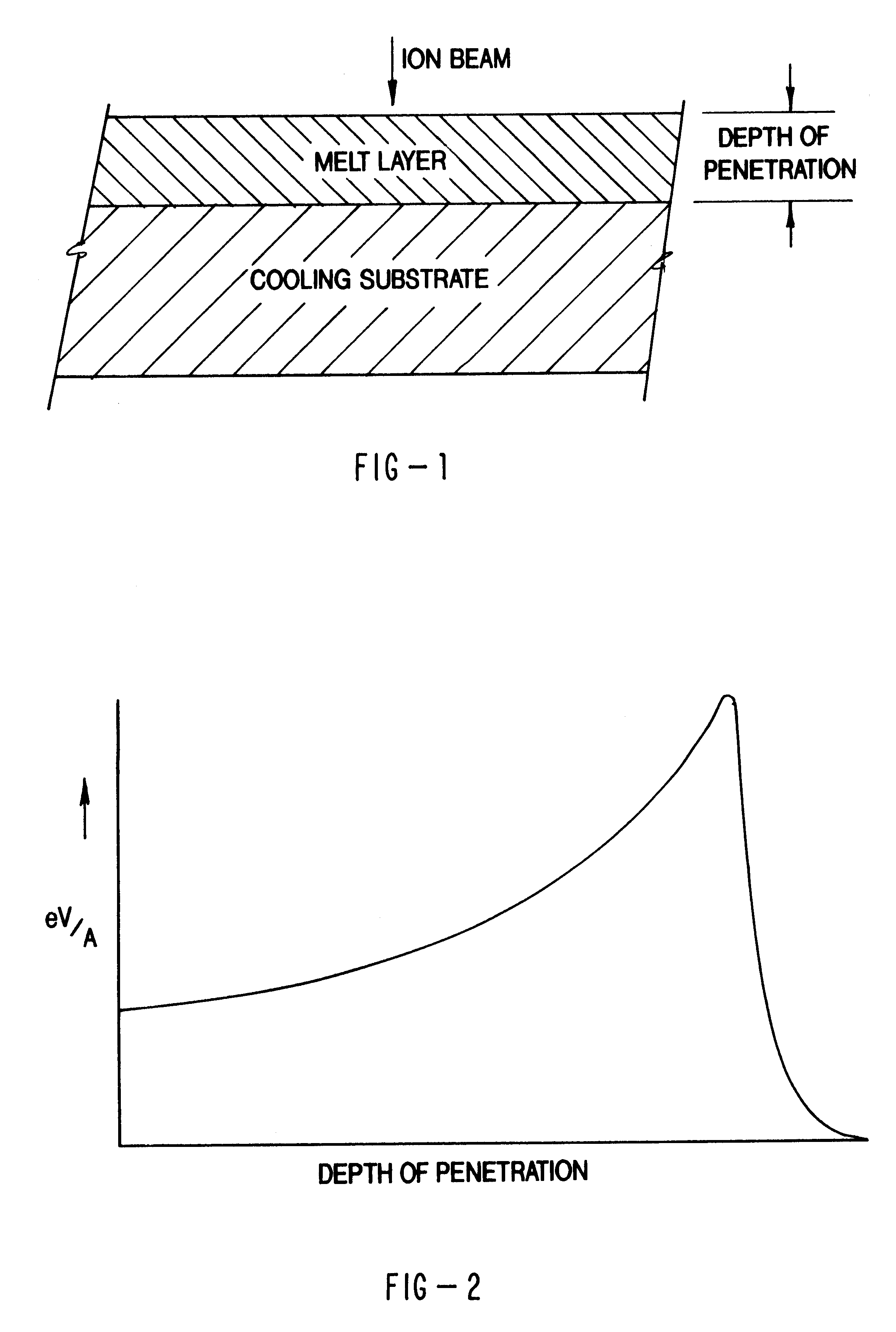

Applications of present invention include production of low cost materials with treated surfaces for handling corrosive environments and treatment of large area metal sheets and critical components used in manufacturing and other areas where hardness, toughness and corrosion or wear resistance are important. It can also be used to produce smooth, crack-resistant ceramic surfaces by melting and re solidification using pulsed ion beams. By varying ion beam deposition levels and pulse durations it is also possible to use this technology for either surface cleaning or annealing. At high deposition levels (.about.30 J / cm.sup.2) it is possible to do shock hardening of materials. Polymer processing and ion implantation can be done at lower deposition levels.

Examples of thermal surface treatment using this process are shown in FIGS. 5, 6, 7a, 7b and 8a, 8b. Surface cleaning or preparation without the use of organic solvents, can be accomplished by choosing higher mass ions (e.g. nitrogen, c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impedance | aaaaa | aaaaa |

| impedance | aaaaa | aaaaa |

| voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com