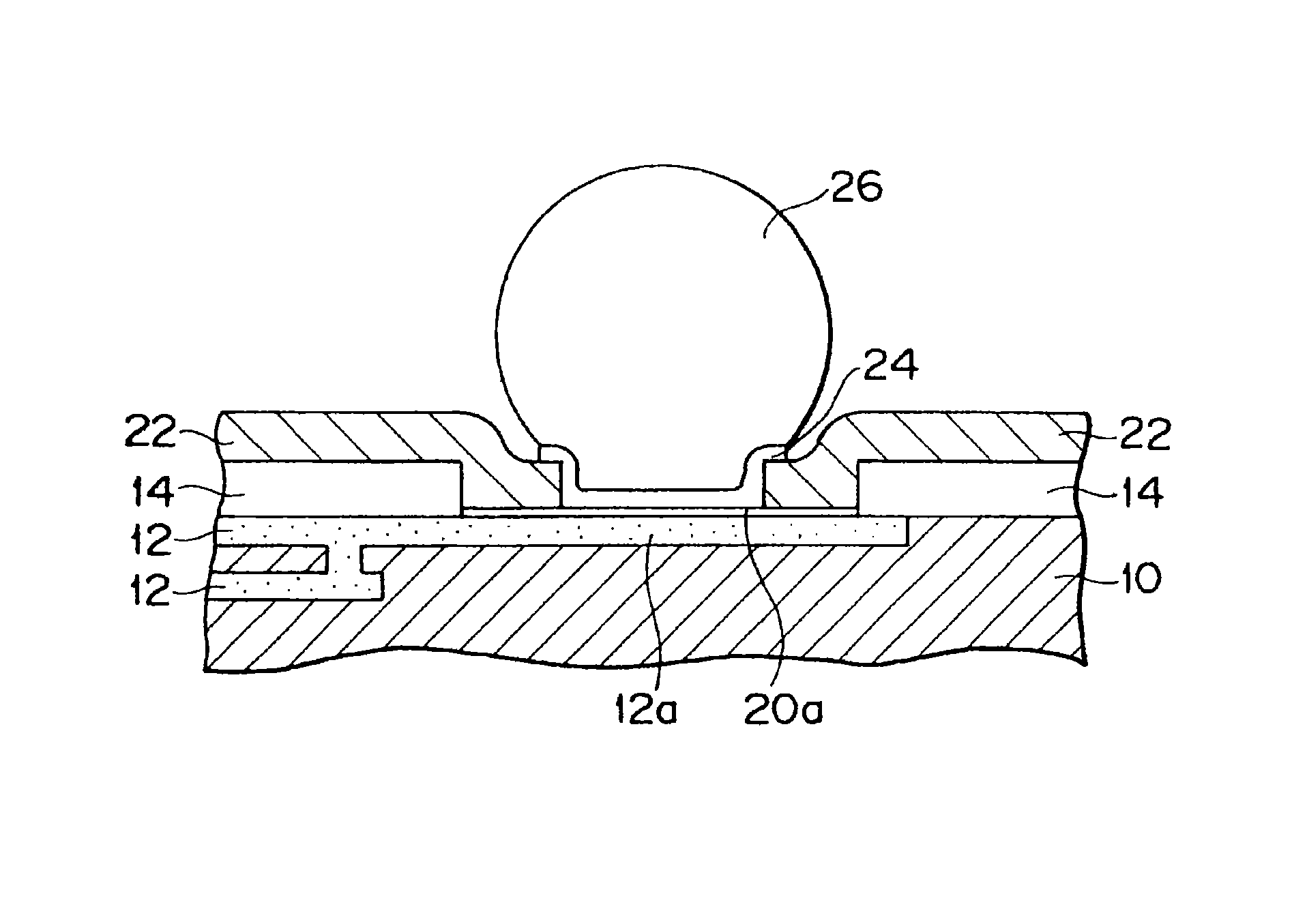

Semiconductor device and method of fabricating the same

a technology of semiconductor devices and semiconductors, applied in semiconductor devices, semiconductor/solid-state device details, electrical apparatus, etc., can solve the problems of affecting the reliability of devices, and tendency toward higher integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

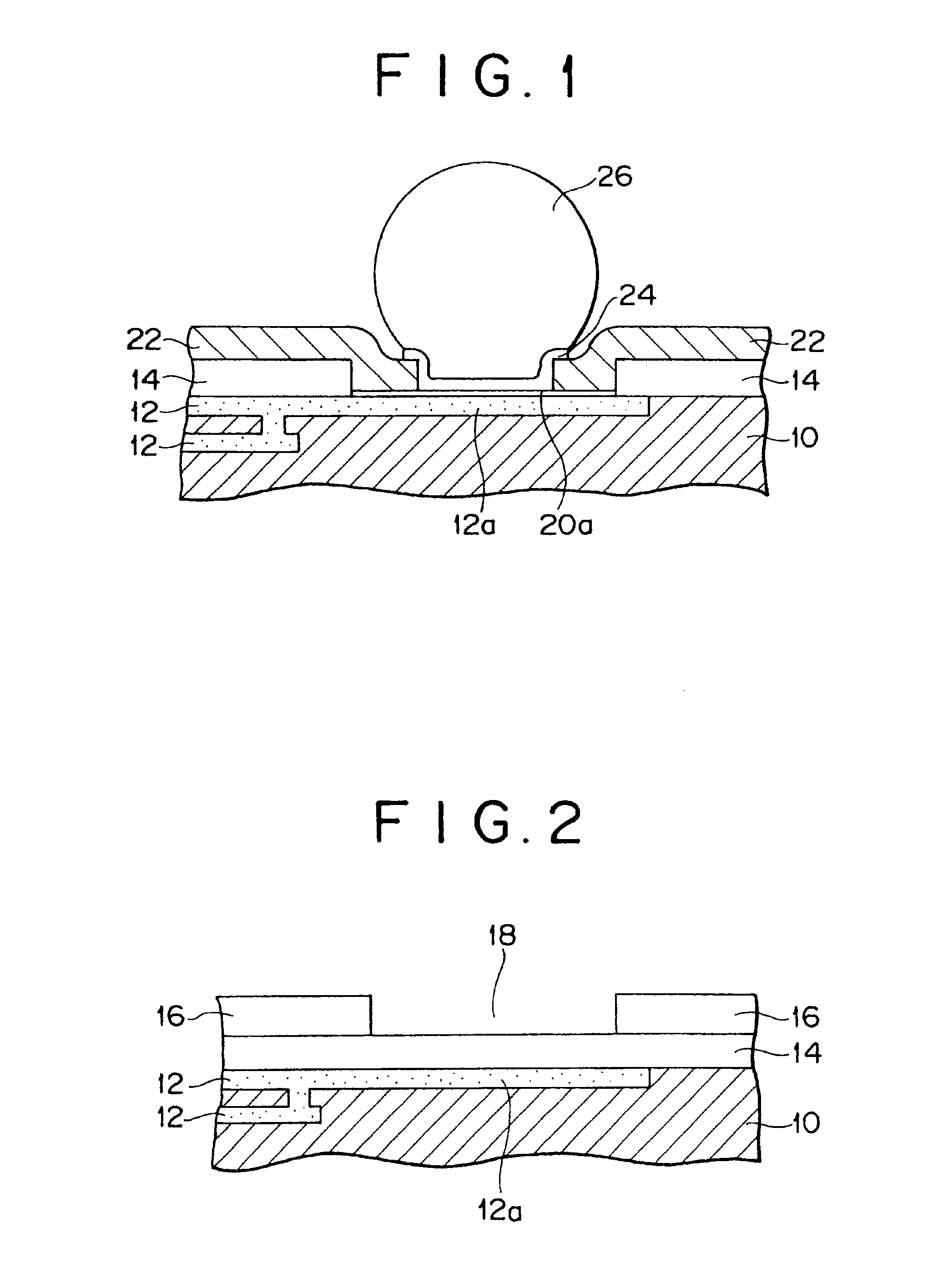

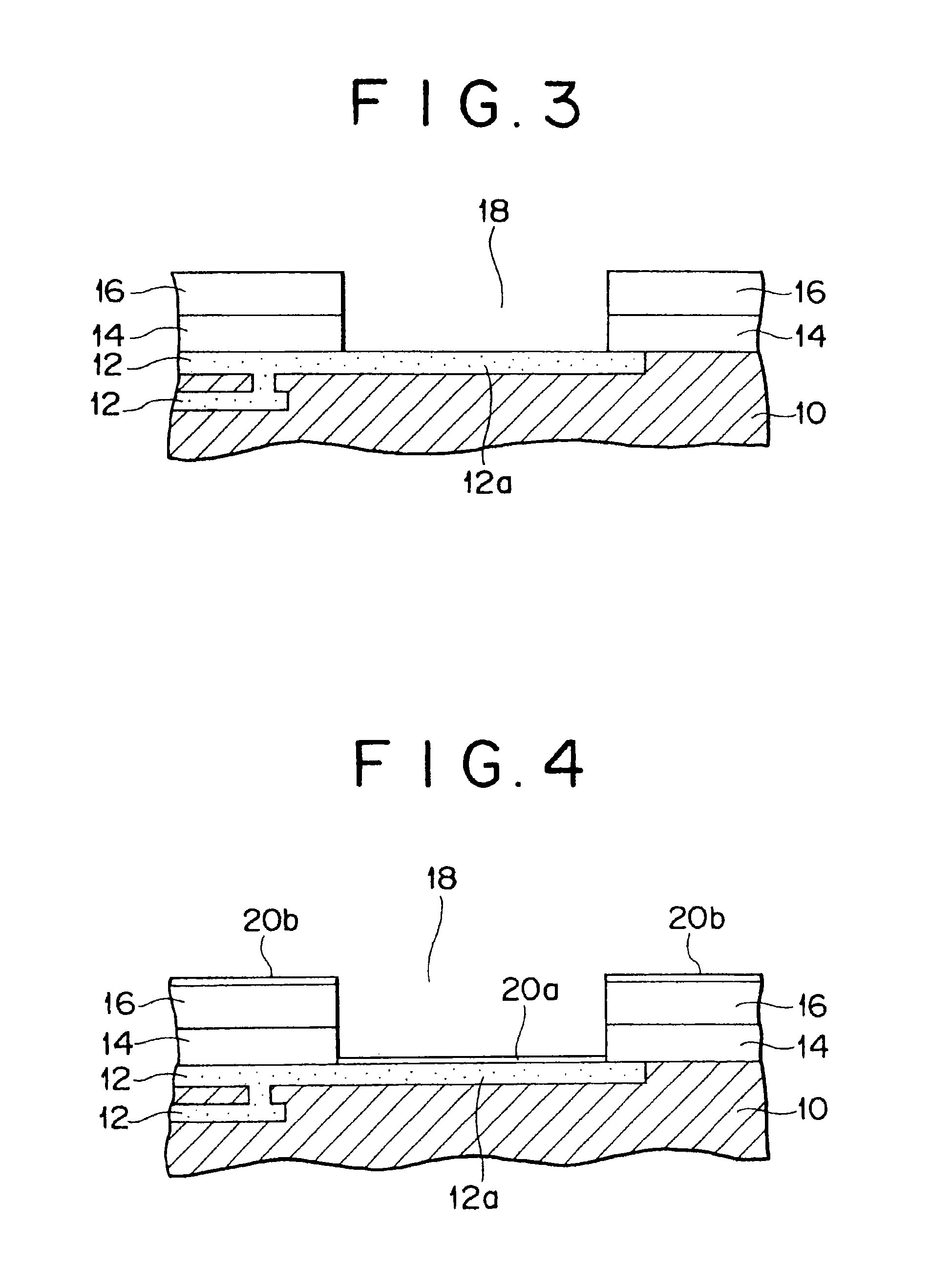

Method used

Image

Examples

example 1

[0058]The selective etching of the silicon nitride film 14 with the resist film 16 taken as a mask was performed using the magnetron RIE apparatus under the following condition:[0059]flow rate of reactive gas: C4F8 / CO=10 / 90 sccm[0060]pressure: 2.0 Pa[0061]RF power: 2.2 W / cm2 [0062]strength of magnetic field: 150 Gauss

[0063]The formation of an Al film as the adhesive layers 20a and 20b was performed using a normal sputter apparatus under the following condition:[0064]DC power: 4.0 kW[0065]flow rate of atmospheric gas: Ar=100 sccm[0066]pressure: 0.5 Pa[0067]temperature of wafer stage: room temperature[0068]thickness of Al adhesion layer: 0.1 μm

[0069]The formation of each of films constituting the BLM film 24 having the stacked structure of Cr / Cu / Au was performed by a normal sputter apparatus under the following condition:

[0070](1) Formation Condition of Cr Film[0071]DC power: 3.0 kW[0072]flow rate of atmospheric gas: Ar=75 sccm[0073]pressure: 1.0 Pa[0074]temperature of wafer stage: 50...

example 2

[0088]The selective etching for the silicon nitride film 14 with the resist film 16 taken as a mask using the magnetron RIE apparatus under the following condition:[0089]flow rate of reactive gas: C4F8 / CO=10 / 90 sccm[0090]pressure: 2.0 Pa[0091]RF power: 2.2 W / cm2 [0092]strength of magnetic field: 150 Gauss

[0093]The formation of a Ti film as the adhesive layers 20a and 20b was performed using a normal sputter apparatus under the following condition:[0094]DC power: 5.0 kW[0095]flow rate of atmospheric gas: Ar=100 sccm[0096]pressure: 0.5 Pa[0097]temperature of wafer stage: room temperature[0098]thickness of Ti adhesion layer: 0.1 μm

[0099]The formation of each of films constituting the BLM film 24 having the stacked structure of Ti / Cu / Au was performed using a normal sputter apparatus under the following condition:

[0100](1) Formation Condition of Ti Film[0101]DC power: 4.0 kW[0102]flow rate of atmospheric gas: Ar=75 seem[0103]pressure: 1.0 Pa[0104]temperature of wafer stage: 50° C.[0105]t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesion | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com