Method for producing biological diesel oil from leftover of edible oil process

A technology of biodiesel and leftovers, which is applied in the field of oleochemicals, can solve the problems of harsh acid-catalyzed reaction conditions, and achieve the effects of controlling urban air pollution, improving reaction efficiency, and shortening reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: Optimization of transesterification reaction conditions

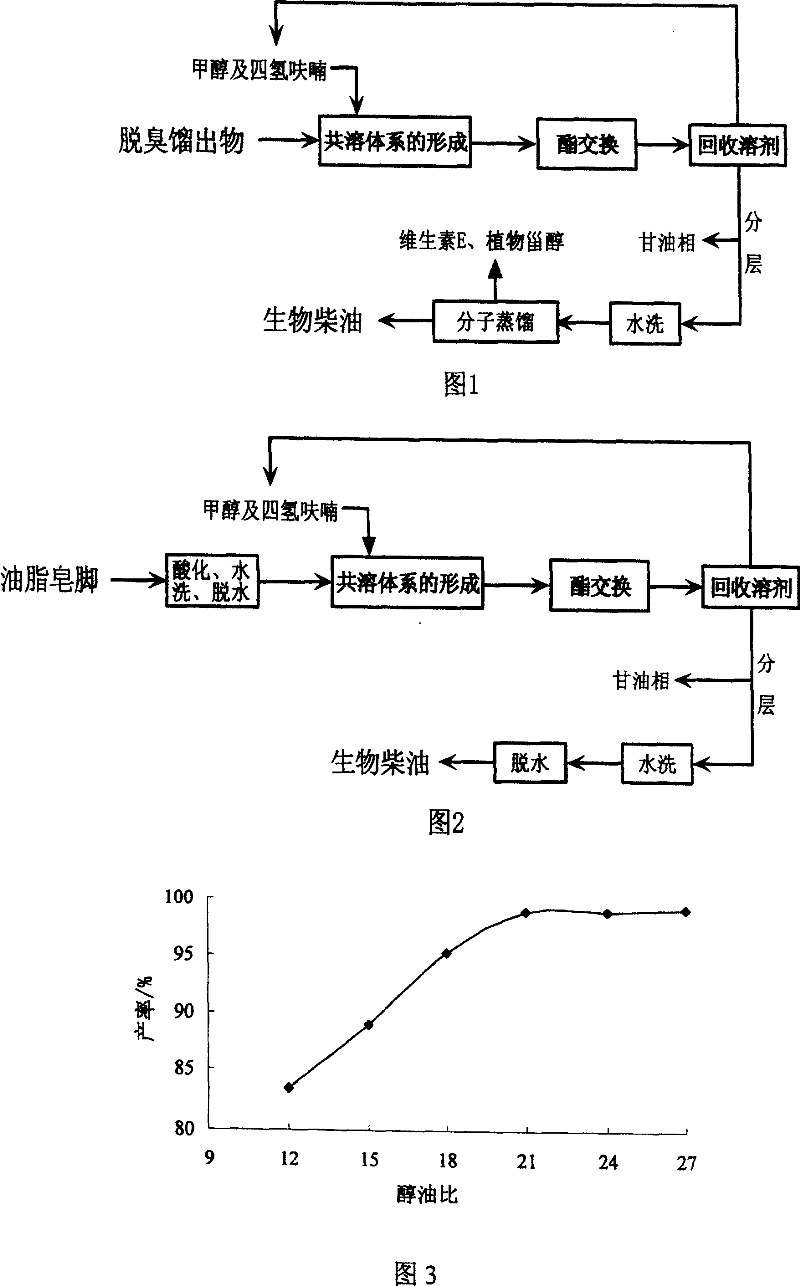

[0030] The process steps are: edible oil processing leftovers are pretreated, methanol is added for transesterification reaction, solvent is recovered, glycerin phase is separated by layers, the oil layer is washed with water, and dehydrated to obtain biodiesel.

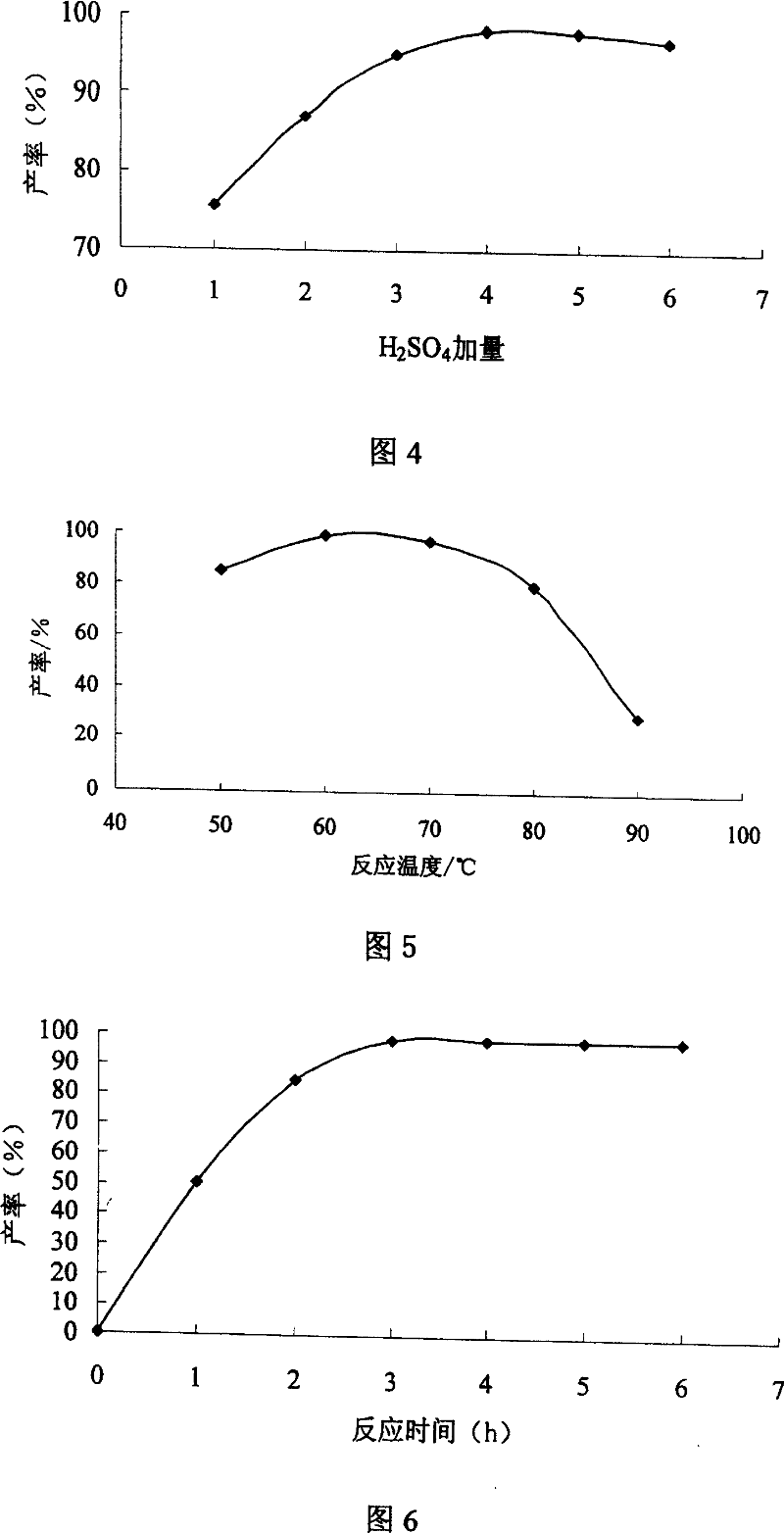

[0031] The effects of alcohol-to-oil ratio, catalyst dosage, reaction temperature and reaction time on reaction yield were investigated through single factor optimization, respectively, as shown in Figure 3-6.

[0032] The influence of the alcohol-oil ratio on the reaction yield: It can be seen from Figure 3 that the reaction yield reaches the optimal value when the alcohol-oil ratio reaches 21:1, and further increasing the alcohol-oil ratio has little effect on the reaction yield. According to the regression curve y=-0.021X 2 +1.3885X+11.401 (y is the amount of tetrahydrofuran (THF) added and X is the alcohol-to-oil ratio). It can be seen that w...

Embodiment 2

[0053] Example 2: Analysis of the physical and chemical properties of biodiesel

[0054] Because the produced biodiesel will be used as an alternative fuel for diesel engine combustion, in order to ensure that biodiesel has good combustion performance, the physical properties of the biodiesel product prepared in Example 1 were compared with the E DIN 51606 quality standard established by Germany. analysis.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com