Cooling fluid of engine

A technology of engine coolant and monobasic acid, which is applied in the field of engine coolant, can solve the problems of large amount of organic additives, containing carcinogens, easy formation of precipitation, etc., and achieves the effects of increasing the boiling point, improving the anti-scaling function, and improving the sterilization function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

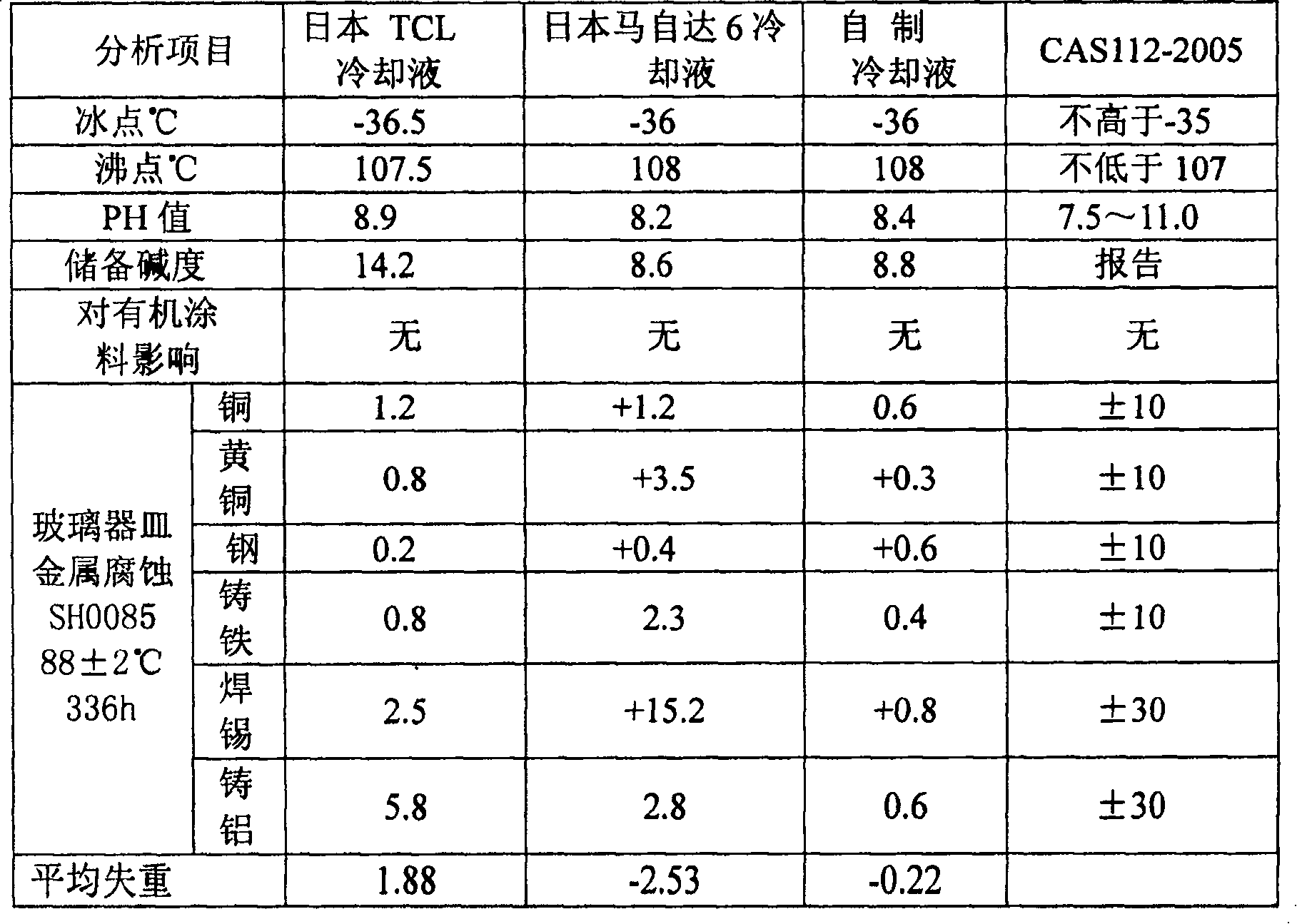

Image

Examples

Embodiment 1

[0039] Embodiment 1: the preparation of polymer

[0040] 30kg ethylene oxide and 30kg lauryl alcohol (also lauryl alcohol) are reacted in an autoclave with 0.3kg potassium hydroxide as a catalyst, refluxed for 3 hours, the reaction temperature is controlled at 100°C, and the vacuum degree is controlled at 0.5MPa. React under vacuum stirring, after making the added mole number of oxirane be 36 moles, the temperature of reaction is lowered to 40 ℃, in the dodecanoic acid (also lauric acid) of adding 60kg in reaction kettle, rely on dodecanoic acid The catalyst performance of the acid itself is not only the raw material to participate in the reaction, but also the catalyst in the reaction process. The temperature is raised to 80°C, and the vacuum degree is controlled at 0.4MPa. After 1.5 hours of reaction, the temperature is raised to 110°C, and the pressure is controlled at 0.65MPa. After constant temperature for 35 minutes, the temperature was raised to 120°C, the pressure was ...

Embodiment 2

[0041] Embodiment 2: the preparation of fluorescent green

[0042] Take water-soluble tartrazine (C 16 h 12 N 4 o 9 S 2 3Na) 0.0001kg and water-soluble brilliant blue (C 37 h 36 N2 o 9 S 3 2Na) 0.0001kg mixed to obtain fluorescent green.

Embodiment 3

[0044] Add 30kg of propylene glycol to the blending kettle, then use the feed pump to extract 69kg of deionized water, place it in the blending kettle to blend with propylene glycol, start a new pulse stirring system, and stir for 10 minutes to make the water and propylene glycol well compatible; Next, add benzotriazole 0.05kg, polymer 0.6kg, sodium benzoate 0.15kg, polyacrylic acid 0.05kg, AEO 9 (fatty alcohol polyoxyethylene (9) ether) 0.05kg, n-octanoic acid 0.05kg, sebacic acid disodium salt 0.05kg, butylparaben (4-hydroxybenzoic acid butyl) 0.0002kg, defoamer (poly Oxyethylene polyoxypropylene monobutyl ether XD-4000) 0.0002kg, fluorescent green 0.0002kg; mixed and stirred at 35±5°C for 30 minutes, tested, filtered and packaged to obtain the engine coolant of this invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com