Preparing process of 5-propionyl-2-thiophenyl phenylacetate

A technology of phenylthiophenylacetate and phenylacetate, which is applied in the field of preparation of 5-propionyl-2-phenylthiophenylacetate and can solve the problem of troublesome solid separation, incomplete reaction and low yield And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

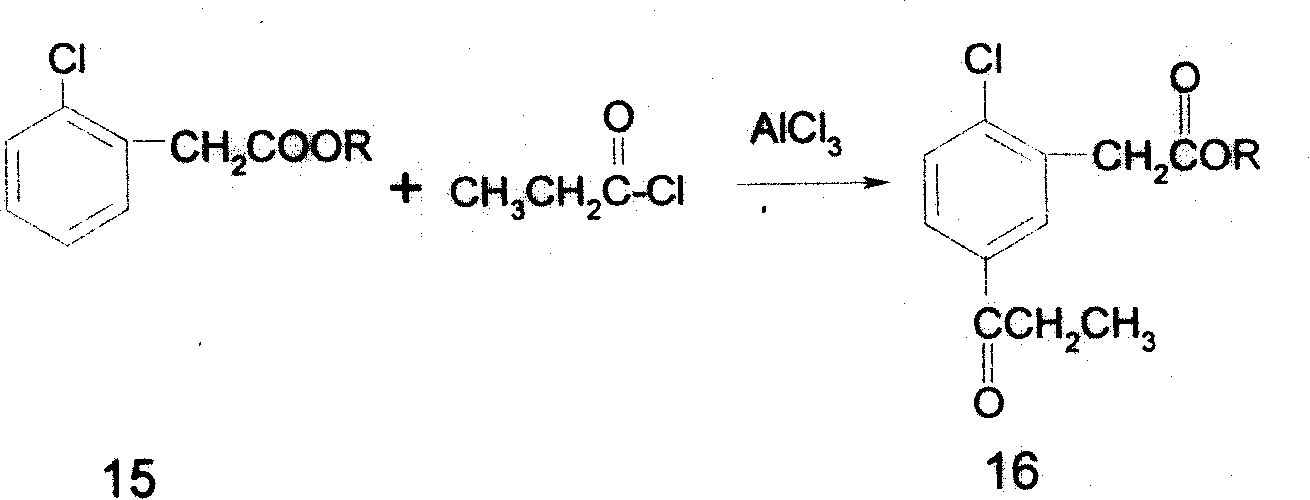

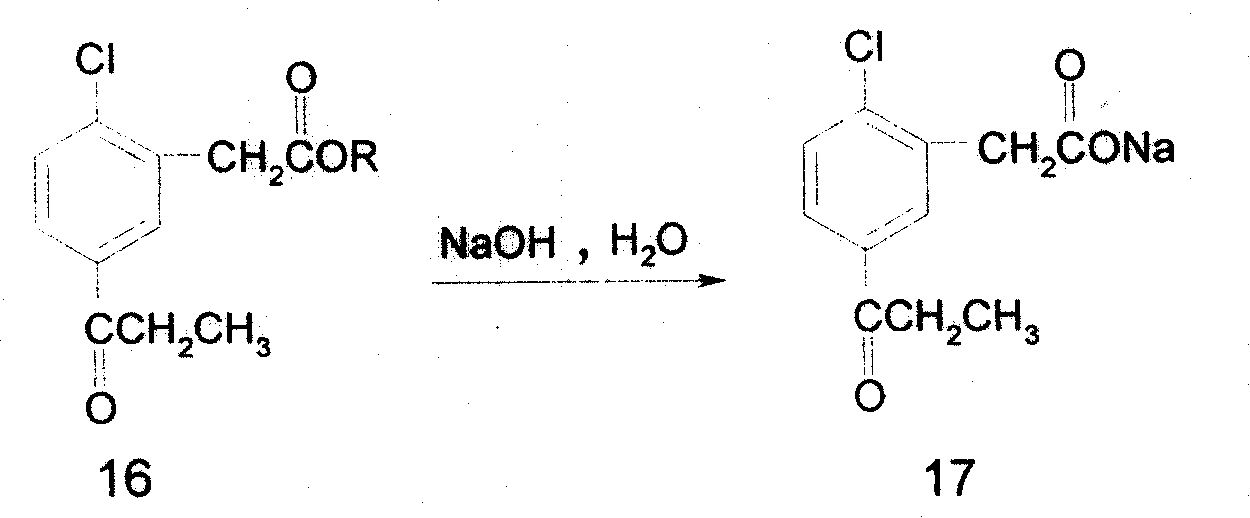

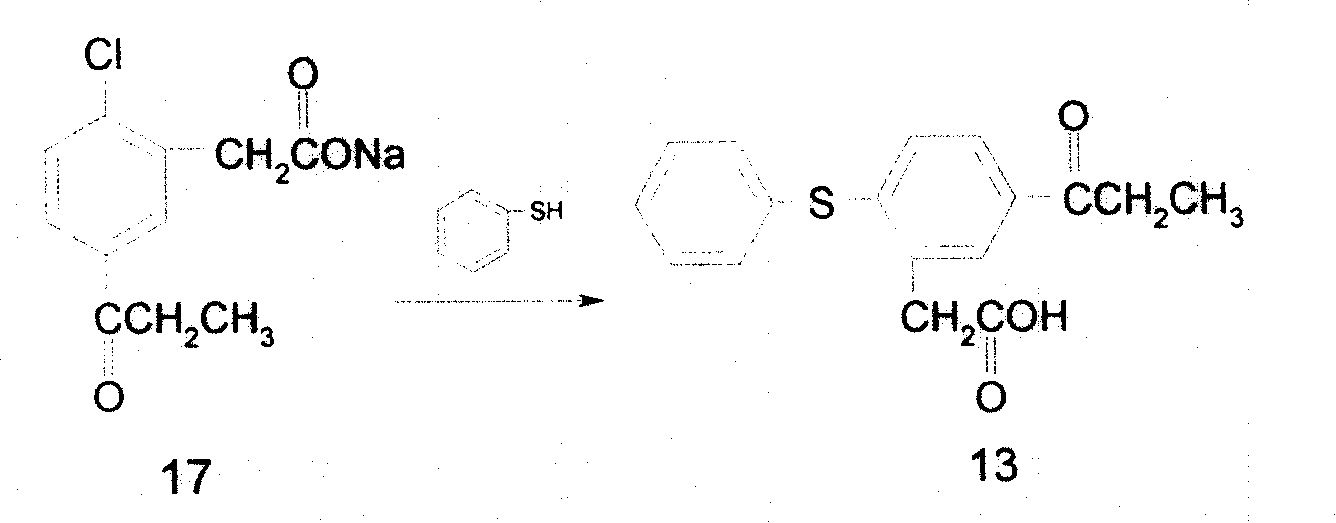

Method used

Image

Examples

Embodiment 1

[0091] 1, the preparation of methyl o-chlorophenylacetate (15)

[0092] Raw material specification and feeding amount

[0093] Raw material (molecular weight)

Specification

Feeding amount

o-Chlorophenylacetic acid (170.5)

Industrial first-class product, white with acetic acid smell

Color powder.MP95~97℃

10Kg

Methanol(32)

Colorless, transparent, flammable and volatile polar liquid

Body ≥ 99%

19Kg

Concentrated sulfuric acid (98)

Colorless transparent oily liquid, strong corrosion,

Content≥98%

1.14Kg

[0094] Feeding ratio (molar ratio):

[0095] O-chlorophenylacetic acid: methanol: concentrated sulfuric acid = 1: 10.12: 0.20

[0096] Add o-chlorophenylacetic acid and methanol to the reaction kettle respectively, stir, add concentrated sulfuric acid dropwise under cooling, heat up and reflux for 10 hours, and remove the solvent. Add water, separate layers, neutralize the or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com