Stable silicone oil based magnetic rheologic liquid, and preparation method

A technology of magnetorheological fluid and silicone oil, applied in magnetic fluid, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of poor suspension stability, easy oxidative deterioration and agglomeration, and achieve low cost and anti-oxidation. Good and significant magnetorheological effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

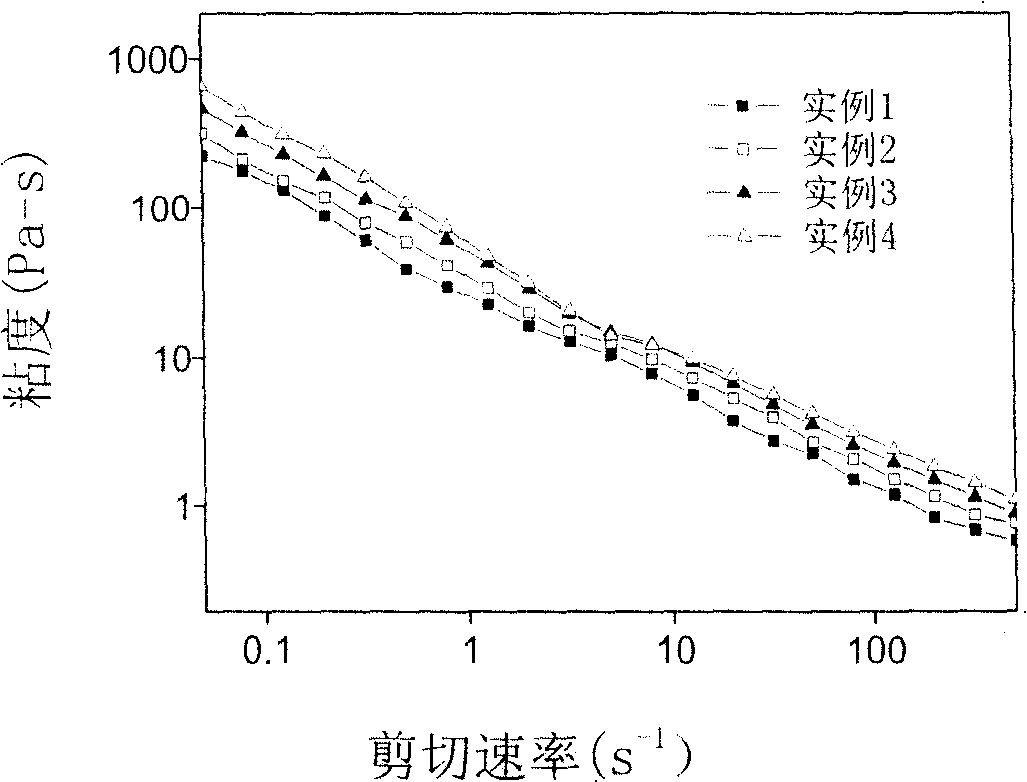

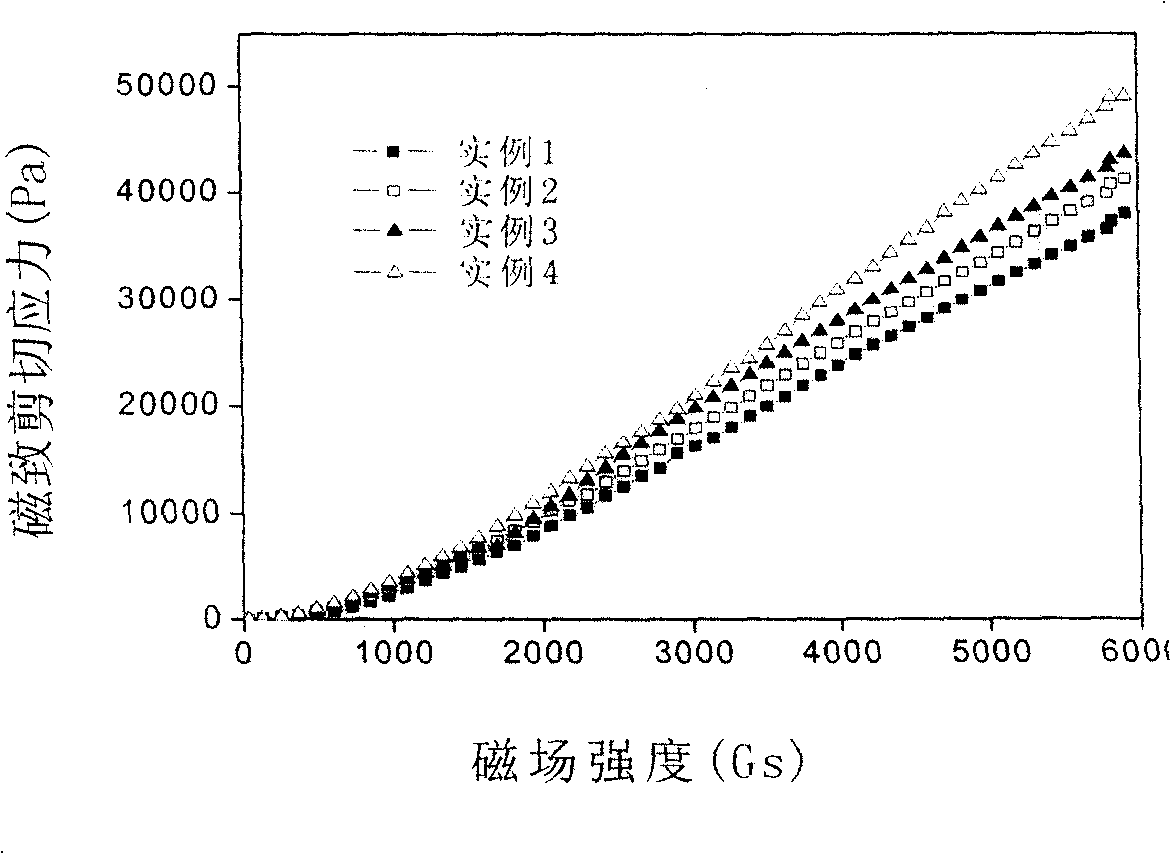

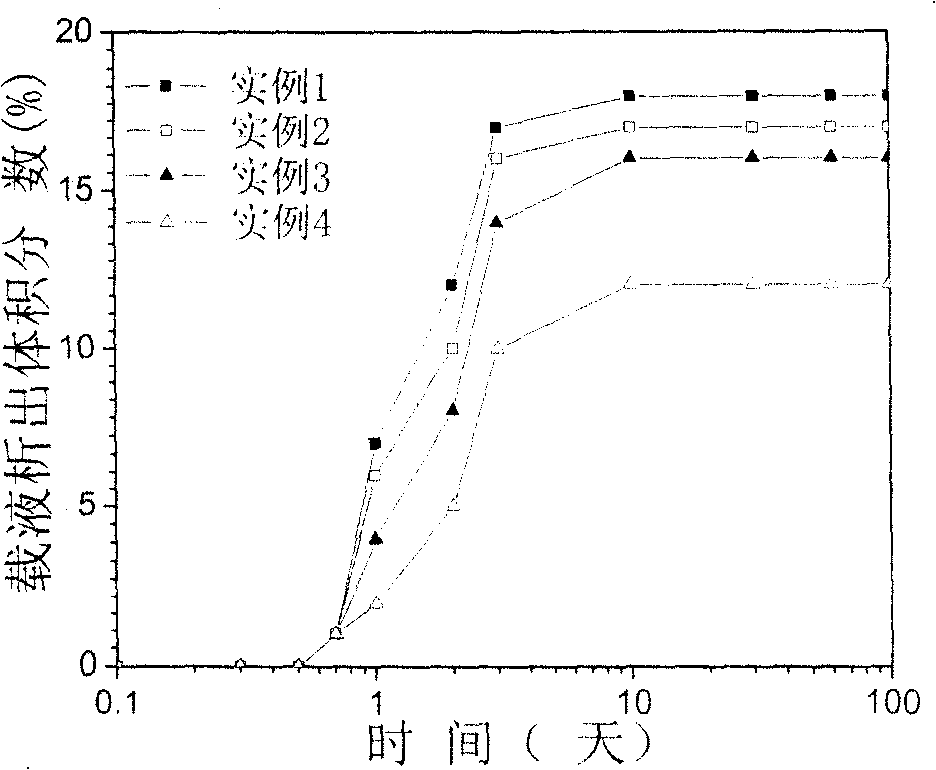

Examples

Embodiment 1

[0036] Prepare 100g of silicone oil-based magnetorheological fluid, the preparation steps are:

[0037] Step 1, adding 2g (2%) surfactant sodium dodecylbenzenesulfonate to 20g (20%) silicone oil, stirring and mixing at room temperature for 3 hours to obtain a mixture;

[0038] Step 2, adding 0.5g (0.5%) antioxidant sodium nitrite to the mixture obtained in step 1, stirring and mixing at room temperature for 3 hours to obtain the mixture;

[0039] Step 3, adding 0.5g (0.5%) thixotropic agent nano magnesium lithium silicate to the mixture obtained in step 2, stirring and mixing at room temperature for 3 hours to obtain the mixture;

[0040] Step 4, adding 2g (2%) antiwear graphite to the mixture obtained in step 3, and stirring and mixing at room temperature for 4 hours to obtain a silicone oil-based compound liquid carrier liquid;

[0041] Step 5. Add 75g (75%) of N-hexadecylethylenediaminetriacetic acid / carbonyl iron core-shell magnetic composite particles (with a particle si...

Embodiment 2

[0050] Prepare 100g of silicone oil-based magnetorheological fluid, the preparation steps are:

[0051] Step 1, adding 3g (3%) surfactant oleic acid into 15g (15%) silicone oil, stirring and mixing at room temperature for 4 hours to obtain a mixture;

[0052] Step 2, adding 0.3g (0.3%) antioxidant sodium benzoate to the mixture obtained in step 1, stirring and mixing at room temperature for 2 hours to obtain the mixture;

[0053] Step 3, adding 0.7g (0.7%) thixotropic polysaccharide to the mixture obtained in step 2, stirring and mixing at room temperature for 4 hours to obtain the mixture;

[0054] Step 4, adding 1g (1%) anti-wear agent nano-alumina powder to the mixture obtained in step 3, stirring and mixing at room temperature for 2 hours, to obtain a silicone oil-based compound carrier liquid;

[0055] Step 5. Add 80g (80%) of N-hexadecylethylenediaminetriacetic acid / carbonyl iron core-shell magnetic composite particles (with a particle size of 1 to 100 microns) to the s...

Embodiment 3

[0064] Prepare 100g of silicone oil-based magnetorheological fluid, the preparation steps are:

[0065] Step 1. Add 2g (2%) surfactant sodium polyether benzene sulfonate to 11g of silicone oil, stir and mix at room temperature for 3 hours to obtain a mixture;

[0066] Step 2, adding 0.2g (0.2%) antioxidant ethanolamine phosphate to the mixture obtained in step 1, stirring and mixing at room temperature for 2 hours to obtain the mixture;

[0067] Step 3, adding 0.3g (0.3%) thixotropic agent cellulose derivative to the mixture in step 2, stirring and mixing at room temperature for 2 hours to obtain the mixture;

[0068] Step 4. Add 1.5g (1.5%) anti-wear agent nano cerium oxide powder to the mixture obtained in step 3, and stir and mix at room temperature for 3 hours to obtain a silicone oil-based composite carrier liquid;

[0069] Step 5. Add 85g (85%) N-lauroyl ethylenediamine triacetic acid / carbonyl iron core-shell magnetic composite particles (with a particle size of 1 to 10...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com