Noninductive planar bus

A plane and busbar technology, applied in the field of high-frequency and high-power power electronic converter processing, can solve the problems of difficult to master the welding process, special materials and processes, long processing cycle, etc., to speed up the development progress, low equivalent inductance, Processing simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

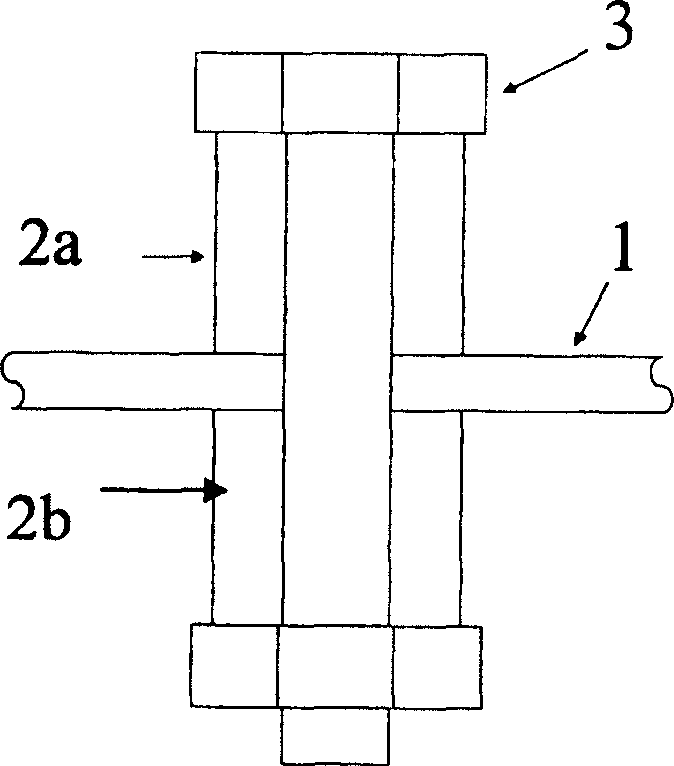

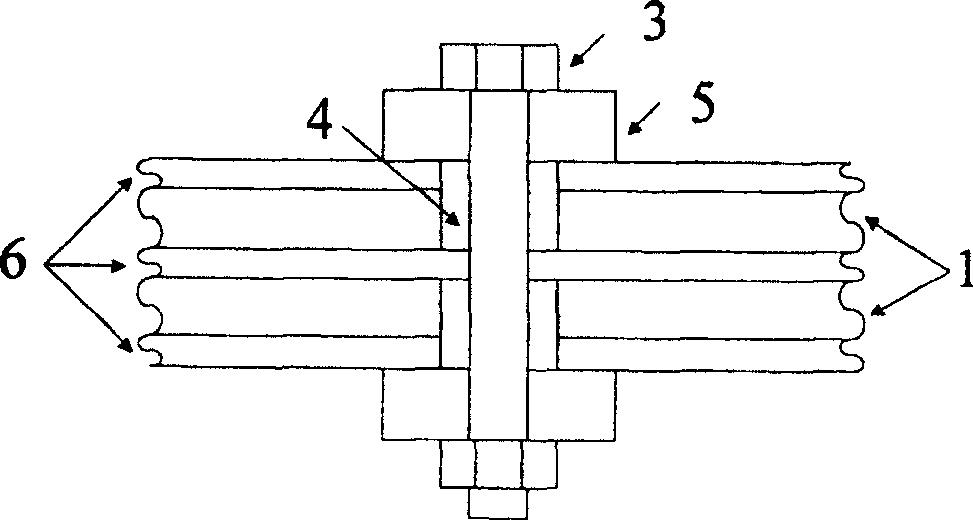

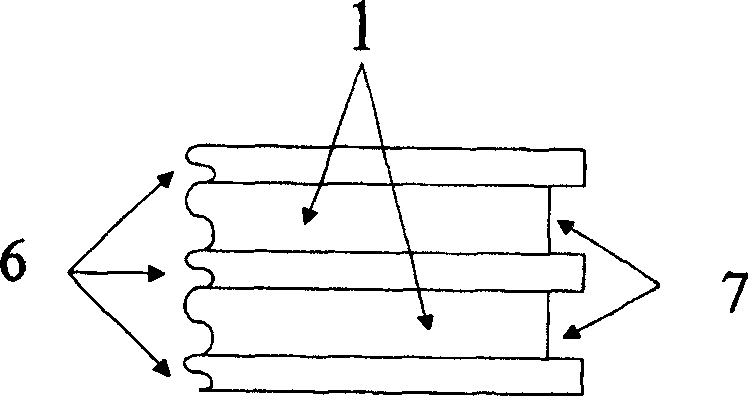

[0026] Take the planar bus applied in 50kVA active power filter (APF) as an example to illustrate.

[0027] The geometry of planar busbars is varied and can be completely planar or a three-dimensional structure with bends. The planar plate busbar structure and simple processing are very suitable for limited process conditions, and the plate busbar with this structure is suitable for most applications. Flat busbars with bending are mainly used in occasions that require high structural compactness, but the process is more complicated. Generally speaking, for the sake of simplicity, the planar busbar is preferred, so the planar busbar used in the 50kVA APF is also planar.

[0028] The length of the DC side circuit of the converter has a great influence on the equivalent inductance of the flat busbar, which requires the circuit layout to be compact. The main components of the DC side circuit of a typical inverter are the main power module and the DC energy storage capacitor. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com