Polyurethane material for improving adhesion growing of cells and rombolytic function

A technology of polyurethane material and cell adhesion, which is applied in the fields of biomedical materials and polymer chemistry, can solve problems such as low cost, and achieve the effects of low cost, easy control, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

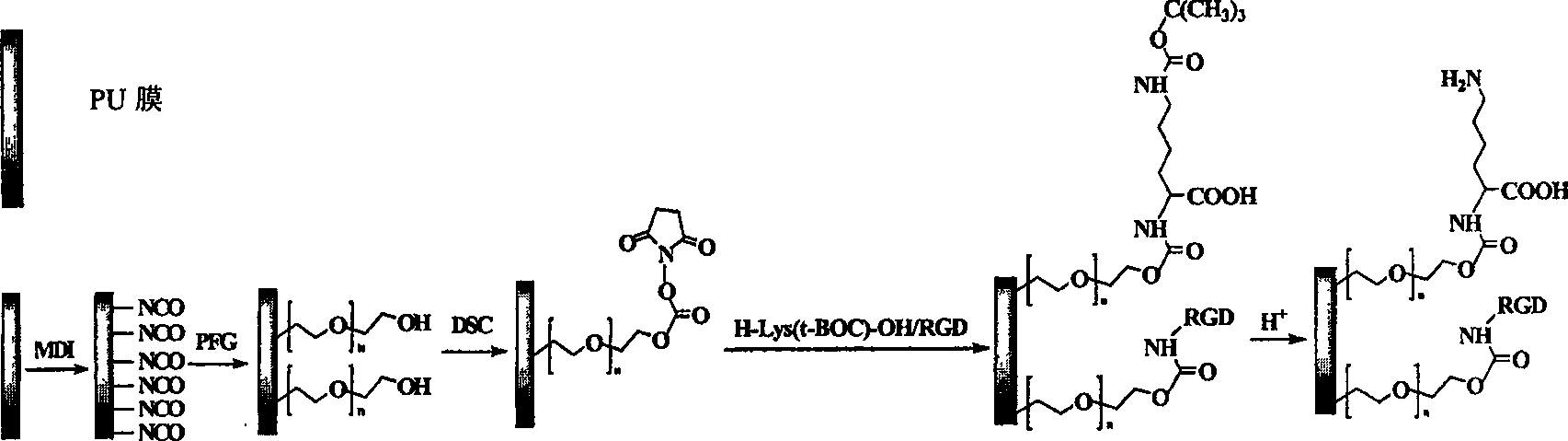

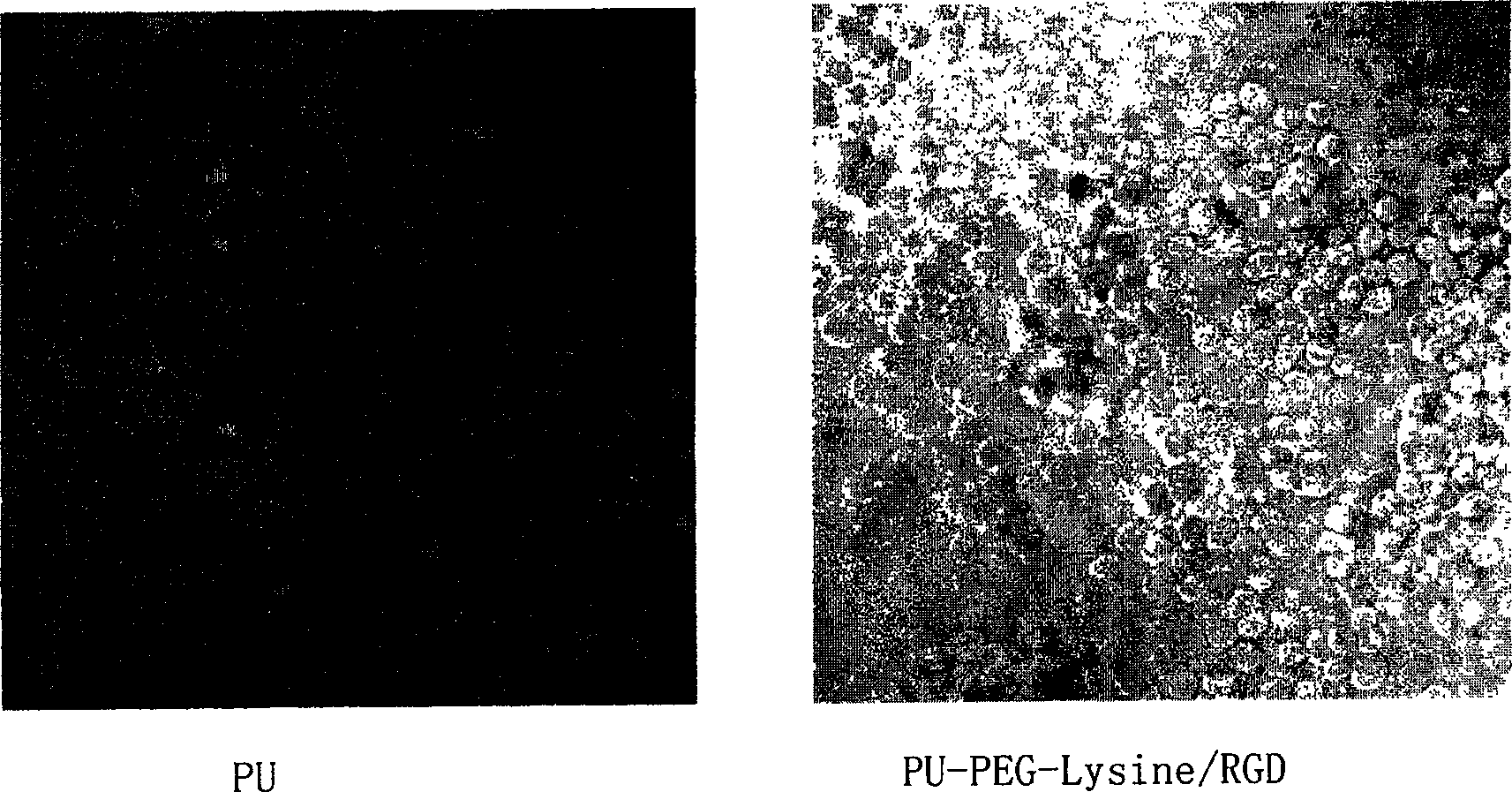

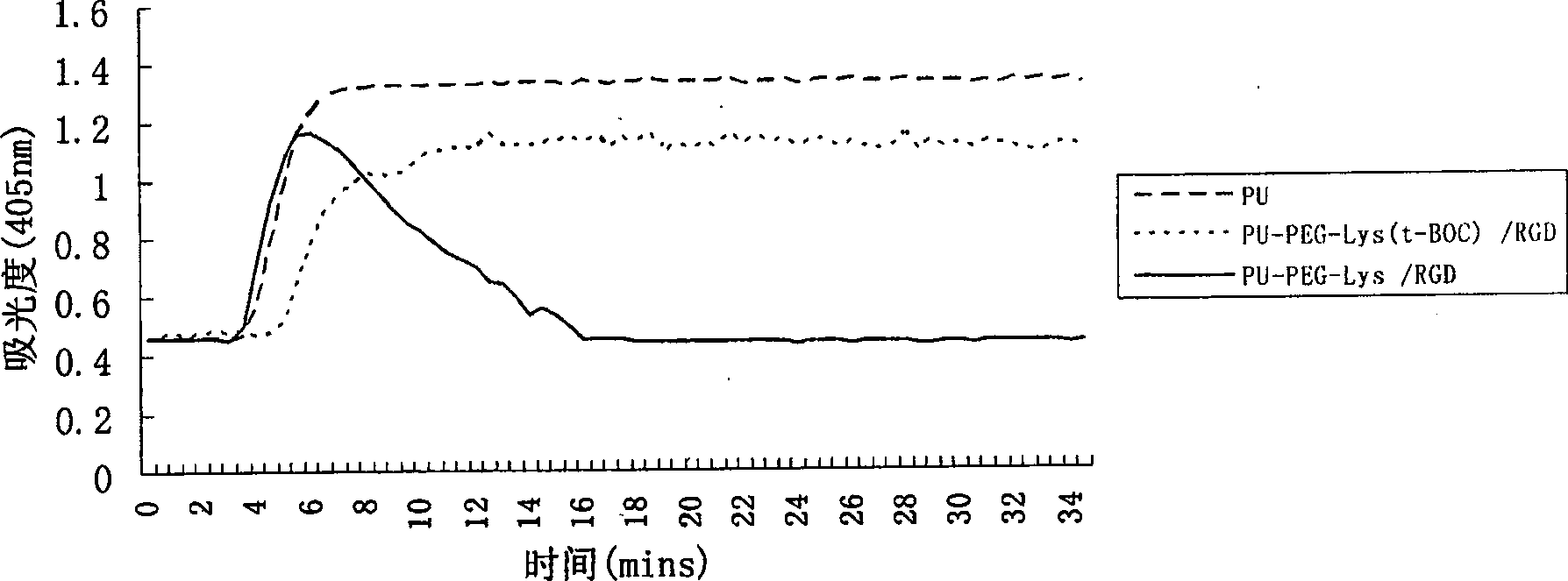

Method used

Image

Examples

Embodiment 1

[0042] First, dissolve the purified granular commercial polyurethane material (product of Shanghai Pengbosheng Polyurethane Co., Ltd.) in N, N-dimethylformamide (DMF), pour it into a flat-bottomed mold, and vacuum dry it after the solvent evaporates. To obtain the PU film, cut the PU film into small pieces with a diameter of 10 mm and a thickness of 0.5 mm, put it into a toluene solution of 5% MDI by mass ratio, stir and heat to 50 ° C, and then pass through N 2 Protection, triethylamine (TEA) according to mass ratio M TEA / M Toluene =2.5% was added to the reaction system, and the reaction was started after mixing evenly. After 60 minutes, the PU film was washed 4 times with toluene. Then put the above-mentioned functionalized PU film into a toluene solution with a mass ratio of 10% polyethylene glycol, heat to 40° C. for reaction under stirring, wash twice with distilled water after 24 hours, and then vacuum dry for 24 hours. Take out the dried PU film, put it into the acet...

Embodiment 2

[0044] Add a magnet in the there-necked flask, weigh 5 grams of polytetrahydrofuran ether glycol (molecular weight is 1000), 5 grams of toluene, and measure 25 mL of DMF, then heat it to 110 ° C with a constant temperature magnetic stirrer and keep it warm for 1 hour. Parts were removed as a toluene azeotrope. Then, its temperature was controlled at 60° C., and then the weighed 4.0 g of MDI and the measured 25 mL of DMF mixed solution were added into the reaction three-necked flask, and the temperature was controlled at this temperature range for 1.5 hours. Then slowly add 0.9 g of chain extender 1,4-butanediol into the three-necked flask with a dropper, raise the temperature to 80° C., and react for 3.5 hours under temperature control. Then pour the reaction solution in the three-neck bottle into the prepared large beaker filled with distilled water along the glass rod, and stir rapidly while pouring to obtain a white viscous product, which is polyurethane. Take it out and pu...

Embodiment 3

[0047] First, the purified granular commercial polyurethane material (product of Shanghai Pengbosheng Polyurethane Co., Ltd.) is dissolved in DMF, poured into a flat-bottomed mold, and then vacuum-dried to obtain a PU film after the solvent is volatilized. The PU film is cut into a diameter of Put a 10mm thick piece of 0.5mm into a toluene solution of MDI with a mass ratio of 6%, stir and heat to 40°C, pass through N2 protection, and mix TEA according to the mass ratio M TEA / M Toluene =2.5% was added to the reaction system, and the reaction was started after mixing evenly. After 120 minutes, the PU film was washed 4 times with toluene. The above-mentioned functionalized membrane was then put into a toluene solution with a mass ratio of 20% polyethylene glycol, heated to 45° C. for reaction under stirring, washed 3 times with distilled water after 16 hours, and then vacuum-dried for 24 hours. Take out the dried PU film, put it into the acetonitrile solution with a mass ratio ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com