Method for synthesizing anatase type crystallizing titanium dioxide nano nuclear-shell or shell structure material by water phase one-step method

An anatase type, titanium dioxide technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve problems such as difficult hydrolysis, and achieve the effects of strong operability, low cost, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

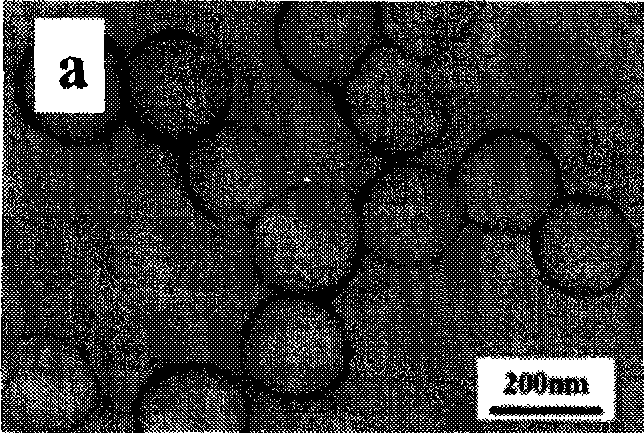

[0029] Take 5g of commercially available polystyrene microsphere powder with a particle size of about 200nm, add 0.25g of cetyltrimethylammonium bromide as a dispersant and ultrasonically disperse it in 1000ml of pure water; Dissolve 30% aqueous hydrogen peroxide solution (ratio of 4 to the number of moles of titanium ions), adjust the pH of the solution to 7 with 2.5% ammonia water, and add 200ml of this solution to the above-mentioned polystyrene emulsion , at a temperature of 80-100 ° C, strong mechanical stirring and reflux reaction for 1 hour, centrifugation at a speed of 2500 rpm to obtain the product, the obtained product was washed three times with pure water and ultrasonically redispersed, and then re-centrifuged to precipitate, then washed with absolute ethanol and ultrasonically Redisperse, centrifuge, and dry to obtain a core-shell structure product.

[0030] The morphology of the resulting product was obtained by transmission electron microscopy (see Figure 1A ) ...

Embodiment 2

[0032] Take 5g of commercially available polystyrene microsphere powder with a particle size of about 200nm, add 0.25g of cetyltrimethylammonium chloride as a dispersant and ultrasonically disperse it in 1000ml of pure water; Dissolve 30% aqueous hydrogen peroxide solution (ratio of 4 to the molar number of titanium ions), adjust the pH of the solution to 3 with 2.5% ammonia water by mass, and add 200ml of this solution to the polystyrene emulsion , at a temperature of 80-100 ° C, strong mechanical stirring and reflux reaction for 1 hour, centrifugation at a speed of 2500 rpm to obtain the product, the obtained product was washed three times with pure water and ultrasonically redispersed, and then re-centrifuged to precipitate, then washed with absolute ethanol and ultrasonically Redisperse, centrifuge, and dry to obtain a product with a shell structure.

[0033] The morphology of the resulting product was obtained by transmission electron microscopy (see Figure 2A ) and sca...

Embodiment 3

[0035] Take 5g of commercially available polystyrene microsphere powder with a particle size of about 500nm, add 0.15g of dodecyltrimethylammonium bromide and 0.15g of dodecyltrimethylammonium chloride as dispersants and ultrasonically disperse in 1000ml In pure water; the orthotitanic acid precipitation is dissolved in 30% aqueous hydrogen peroxide solution (with the molar ratio of titanium ions being 4) with a mass percent concentration, and the pH of the solution is regulated by 2.5% ammonia solution 7. Add 200ml of this solution into the above polystyrene emulsion, at a temperature of 80-100°C, reflux with strong mechanical stirring for 1 hour, centrifuge at 2500rpm to obtain the product, wash the obtained product three times with pure water and redisperse it ultrasonically Afterwards, re-centrifuge to precipitate, then wash with absolute ethanol and redisperse by ultrasonication, centrifuge to precipitate, and dry to obtain a core-shell structure product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com