Method for preparing anode material gamma-LiV2O5 of lithium ion battery

A cathode material, lithium battery technology, applied in the field of γ-LiV2O5 synthesis, can solve the problems of long time, limited output, unsuitable for mass production, etc., and achieves the effects of low cost, short holding time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

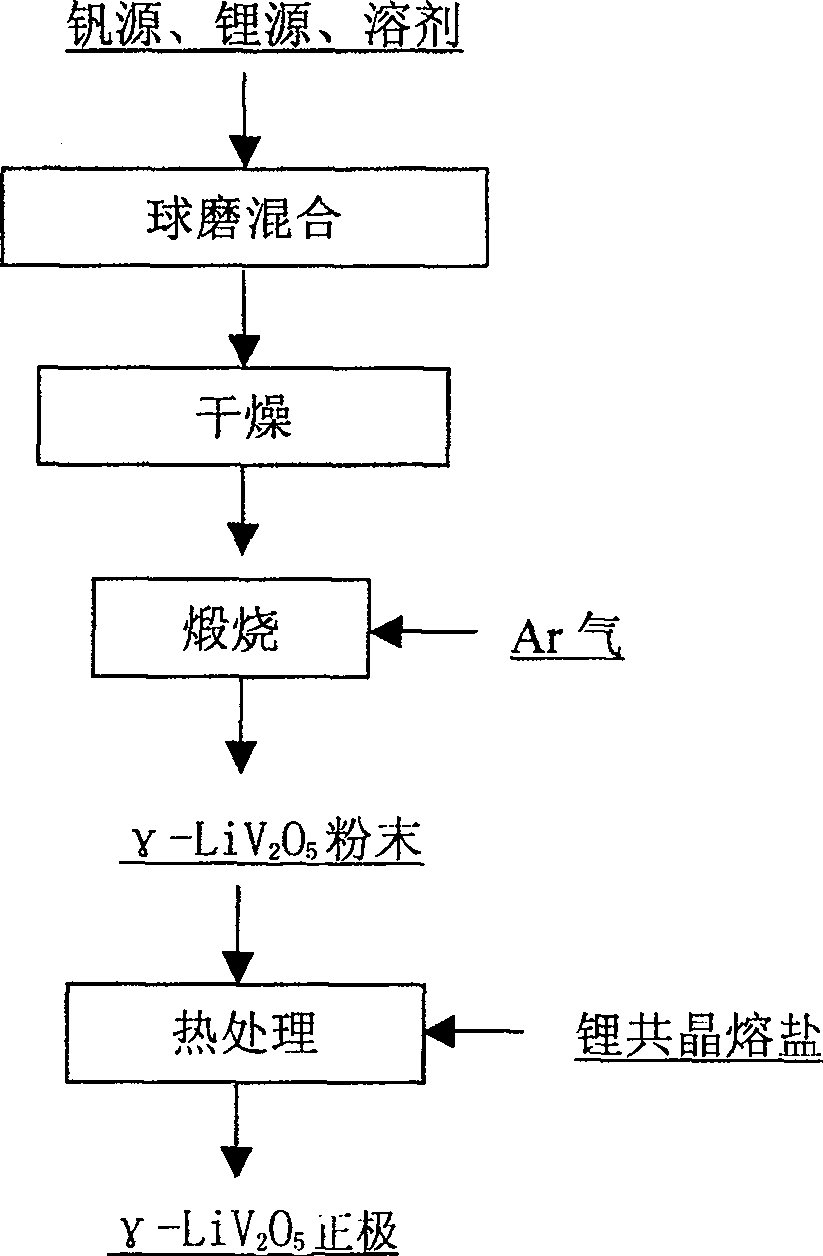

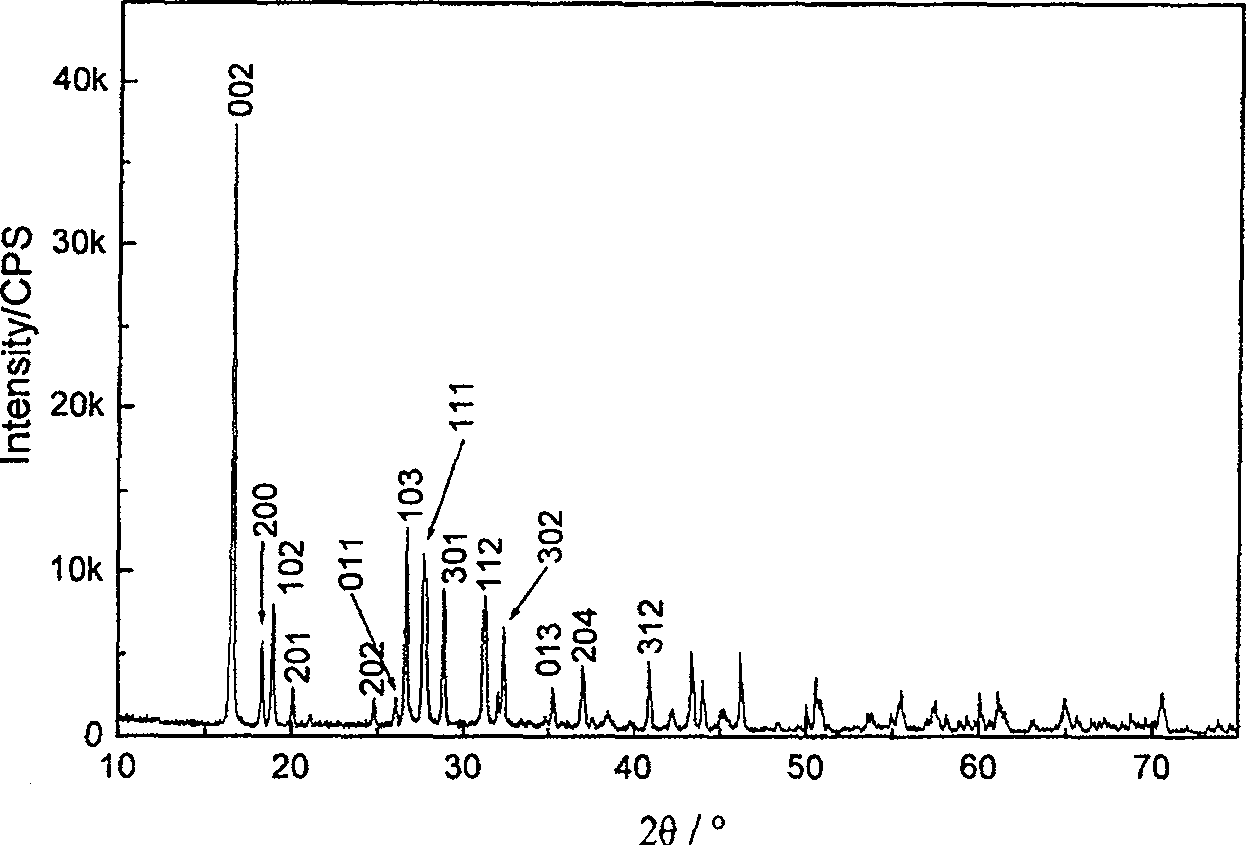

[0027] (1) γ-LiV 2 o 5 powder preparation

[0028] 86.7g of analytically pure V 2 o 5 , 60g analytically pure LiBr·H 2 O. 200ml of absolute ethanol was mixed with polytetrafluoroethylene balls for 8 hours (i.e. LiBr·H 2 O excess 20wt%), the slurry was heated in a 90°C water bath until the absolute ethanol escaped to obtain a pasty slurry. Then it was dried in vacuum at 120° C. for 4 hours, and a gray-green powder was obtained after passing through a 100-mesh sieve. The gray-green powder was calcined at 600°C for 4 hours in flowing argon, and passed through a 100-mesh sieve after grinding to obtain γ-LiV 2 o 5 powder. Br produced during the preparation 2 Steam can be absorbed by tap water. All sieving operations were carried out in a glove box filled with dry air to avoid moisture absorption of the powder.

[0029] (2) γ-LiV 2 o 5 High temperature cathode discharge test

[0030] Simulated Li-B / LiCl-KCl / γ-LiV 2 o 5 Discharge test of sheet-type cells at 500°C. Li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com