Humic acid releasing-controlled fertilizer and preparation method thereof

A technology of controlled-release fertilizer and humic acid, applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of impact resistance, low wear resistance, low effective nutrient content of controlled-release fertilizer, high production cost, etc., to increase microbial community, improving crop quality, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

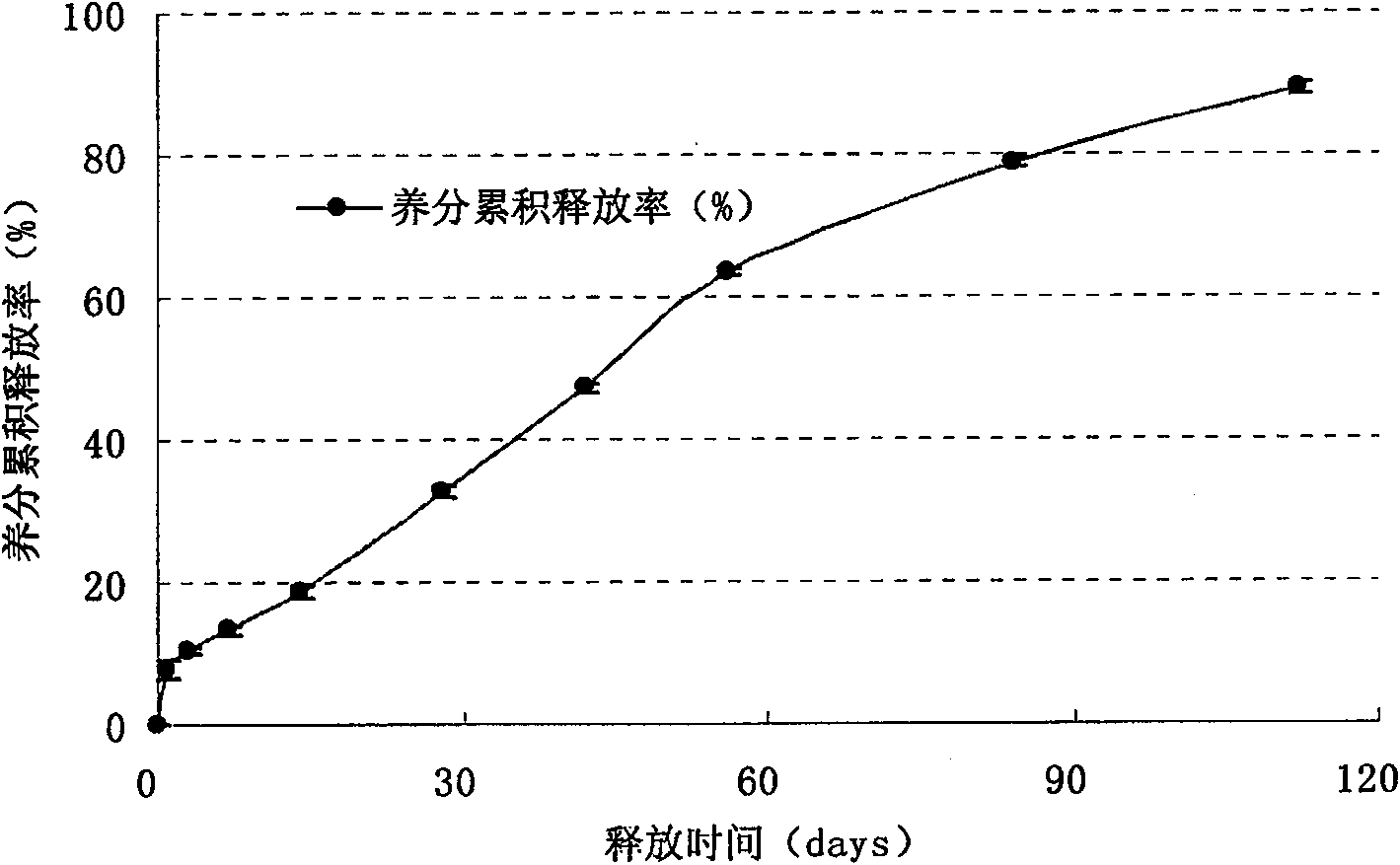

[0027] Example 1, preparing humic acid controlled-release fertilizer with a controlled-release period of 7 months.

[0028] Weigh 500kg of diammonium phosphate (18-46-0) granular fertilizer, preheat to 60°C in a disc granulator, and mix 1.38kg of epoxy resin and 0.12kg of epoxy resin curing agent T-31 (Tianjin Yanhai Chemical Co., Ltd.) mixed evenly and added to the moving fertilizer particles, with the continuous movement of the fertilizer particles, a cohesive liquid layer is formed on the surface, and the weighed 10kg air-dried and pulverized weathered coal is sprinkled on the disc for granulation On the fertilizer in the machine, continue to heat and keep the temperature at 60°C. With the continuous rotation of the granulator, the weathered coal powder is evenly wrapped on the surface of the fertilizer, and it can be solidified into a film after about 6 minutes; the coating material weighed according to the above 500kg of diammonium phosphate fertilizer and then repeatedly...

Embodiment 2

[0029] Example 2, preparing humic acid controlled-release fertilizer with a controlled-release period of 9 months.

[0030] Weigh 500kg of Shima brand compound fertilizer (15-15-15) granular fertilizer from BASF, Germany, preheat to 65°C in a disc granulator, mix 2.25kg epoxy resin and 0.25kg triethylenetetramine evenly and add On the moving fertilizer granules, with the continuous movement of the fertilizer granules, a cohesive liquid layer is formed on the surface, and the weighed 15kg air-dried and pulverized weathered coal is sprinkled on the fertilizer in the disc granulator, and continues to heat and keep The temperature is 70°C. With the continuous rotation of the granulator, the weathered coal powder is evenly wrapped on the surface of the fertilizer, and it can be solidified into a film after about 5 minutes; -15-15 fertilizers are repeatedly wrapped three times to obtain a humic acid controlled-release fertilizer with a total coating rate of about 12%wt and a control...

Embodiment 3

[0031] Example 3, preparing humic acid controlled-release fertilizer with a controlled-release period of 9 months.

[0032] Weigh 1000kg of 46-0-0 large granule urea, preheat it to 70°C in the drum, mix 4.5kg epoxy resin and 0.5kg T-31 evenly and add it to the moving fertilizer granules, and keep moving with the fertilizer granules , form a cohesive liquid layer on its surface, sprinkle 100kg of air-dried and pulverized lignite on the fertilizer in the disc granulator, continue to heat and keep the temperature at 65°C, and with the continuous rotation of the granulator, the weathering The coal powder is evenly wrapped on the surface of the fertilizer, and it can solidify into a film after about 5 minutes. A humic acid controlled-release fertilizer with a total coating rate of about 11%wt and a controlled release period of 9 months can be obtained, which is packaged and put into storage after cooling.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com