Disperse system of nano composition colloid of polythiophene, and preparation method

A colloidal dispersion and nano-composite technology, applied in the field of polymer materials, can solve the problems of not meeting the requirements of electronic level, low material utilization rate and industrial benefit, and low resistivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

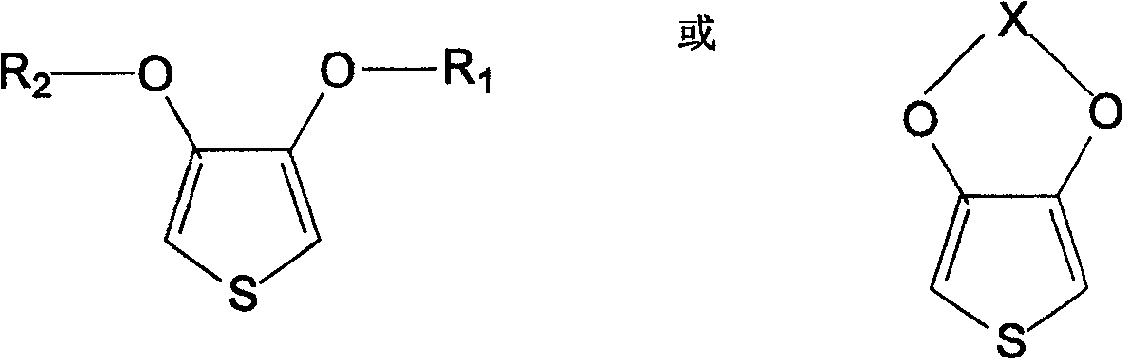

Method used

Image

Examples

Embodiment 1

[0027] In the presence of oxidant air, the polymerization reaction temperature is room temperature, 1.5g of 3,4-ethylenedioxythiophene and 3.18g of polyethylene sulfonic acid (Mn=120000) are added to 200ml of deionized water, and 0.15g of Polyethylene glycol 600, blowing air into the air, stirring at 6000rpm, adding an acid-base modifier, controlling the pH of the system to be below 2, stirring for 15 hours, reaction temperature 60°C, and finally ultrasonically dispersing for 3.0 hours. At the end of the reaction, a blue-black polymer dispersion system is formed.

[0028] The dispersion was put into a dialysis bag after active treatment (maximum dialysis Mn = 7000) for countercurrent dialysis. After 30 hours, the pH of the system was measured to be 1.50, and the solid content (100° C., 6 hours) was 1.50%. Ion content: Na + , 350ppm; SO 4 2- , 100ppm. The maximum particle diameter is less than 100nm.

[0029] The element analysis data of the finished colloidal dispersion s...

Embodiment 2

[0031] 10g of ethylenedioxythiophene, 400g of 5.99% polystyrene sulfonate sodium (PSSA) and 2062ml of deionized water were mixed and stirred, and after initial stirring for 10min at room temperature, 3.0g of polyethylene glycol 1200 was added to the system , high-speed airflow impact, the stirring rate reaches 12000rpm, add 22.5g of oxidant potassium persulfate, and at the same time add a certain amount of acid-base mediator to control the pH value of the system below 3.0 during the reaction, the stirring reaction time is 24h, and the reaction temperature is 20-40 ℃. Then ultrasonically dispersed for 5h. After the reaction, a blue-black aqueous polymerization dispersion system is formed, the measured pH of the system is 2.5, the solid content is 1.67%, and the maximum particle diameter is less than 100nm. The removal method of small molecule organic matter and impurity ions is the same as that in Example 1 to obtain a colloidal dispersion system, ion content: Na + , 250ppm; ...

Embodiment 3

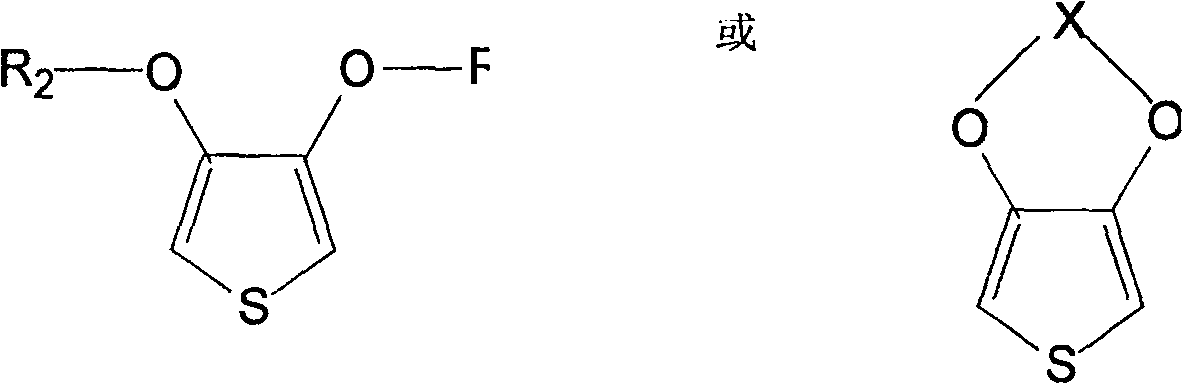

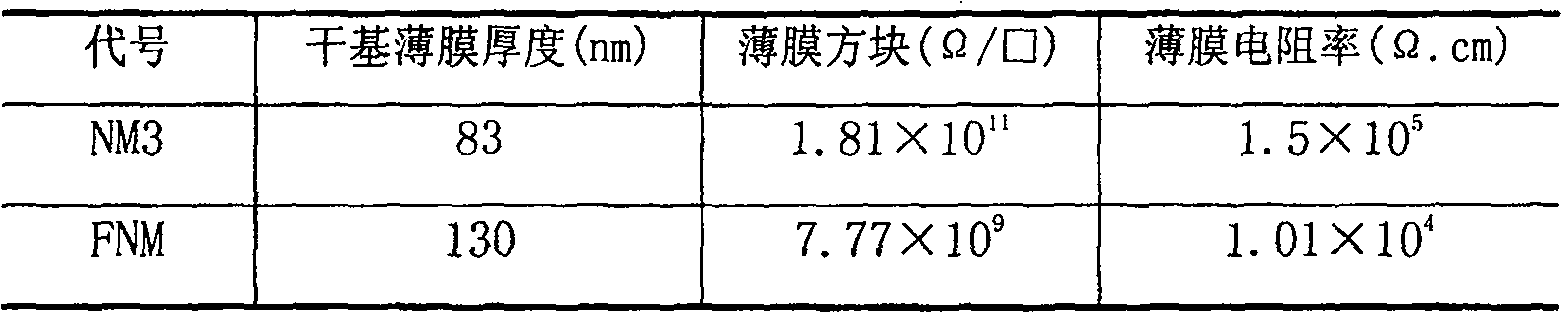

[0033] Add 20g of PSS (Mn=50000) to 2000ml of deionized water, and at the same time add 8.0g of 3,4-dimethoxythiophene. After initial low-speed stirring for 20min, add 21.4g of the oxidizing agent ammonium persulfate, and the mixture is stirred at room temperature at high speed. Airflow impact, high-speed stirring (8000rpm) to control the pH value below 4, after reacting for 20 hours, add 10g PSS again, and ultrasonically disperse for 4 hours to obtain a blue-black dispersion liquid. The removal method of small molecular organics and impurity ions is as in Example 1. In the final colloidal dispersion system, the measured liquid solid content was 2.67%, and the pH of the solution was 1.28. Ion content: Na + , 300ppm; SO 4 2- , 90ppm. The maximum particle diameter is less than 100nm. Code NM3, storage time > 8 months at 10°C.

[0034] The comparative example of example 3 (non-nanometer composite dispersion system FNM)

[0035] Add 20g of PSS (Mn=50000) to 2000ml of deioniz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com