coo/comoo 4 Preparation of composite materials and their application in lithium-ion batteries

A lithium-ion battery and composite material technology, applied in the field of micro-nano material synthesis, can solve the problems of cycle, poor rate performance, low conductivity, poor lithium battery performance, etc., and achieve the effects of complete structure, good crystallinity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

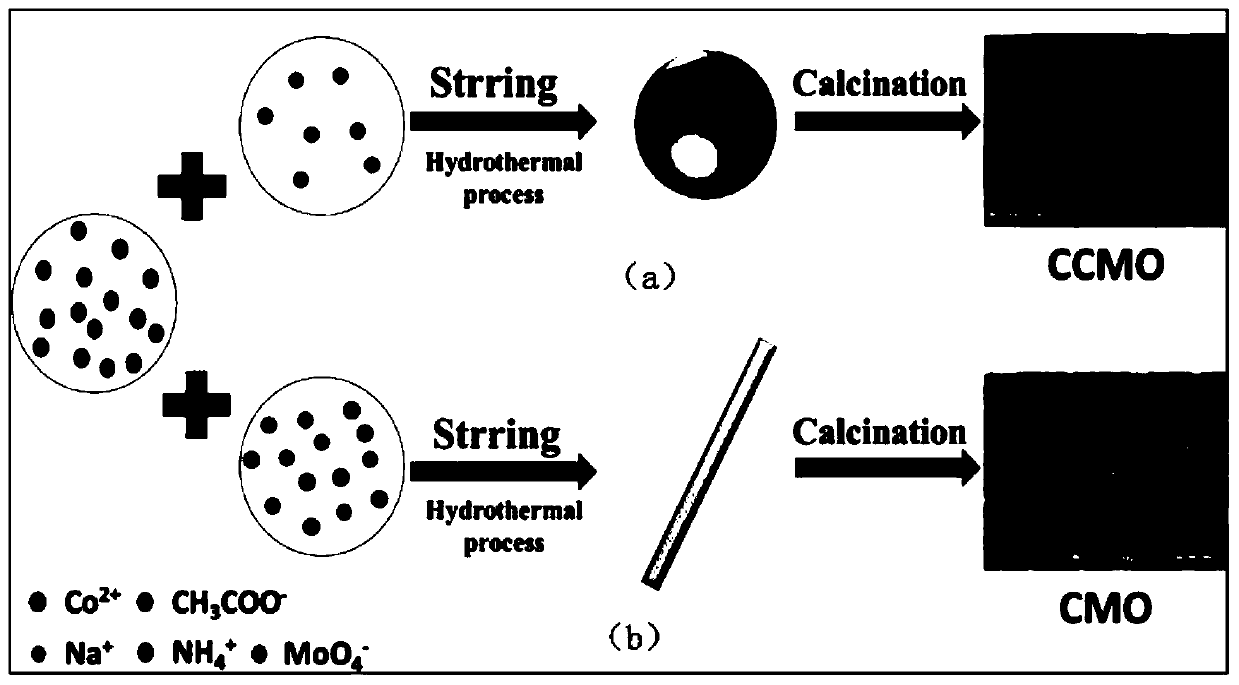

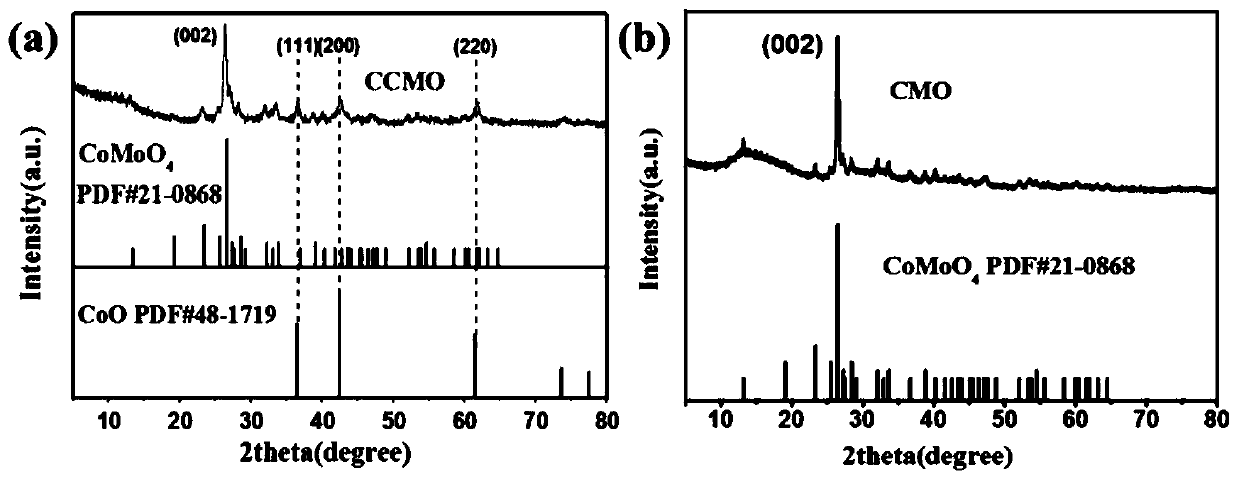

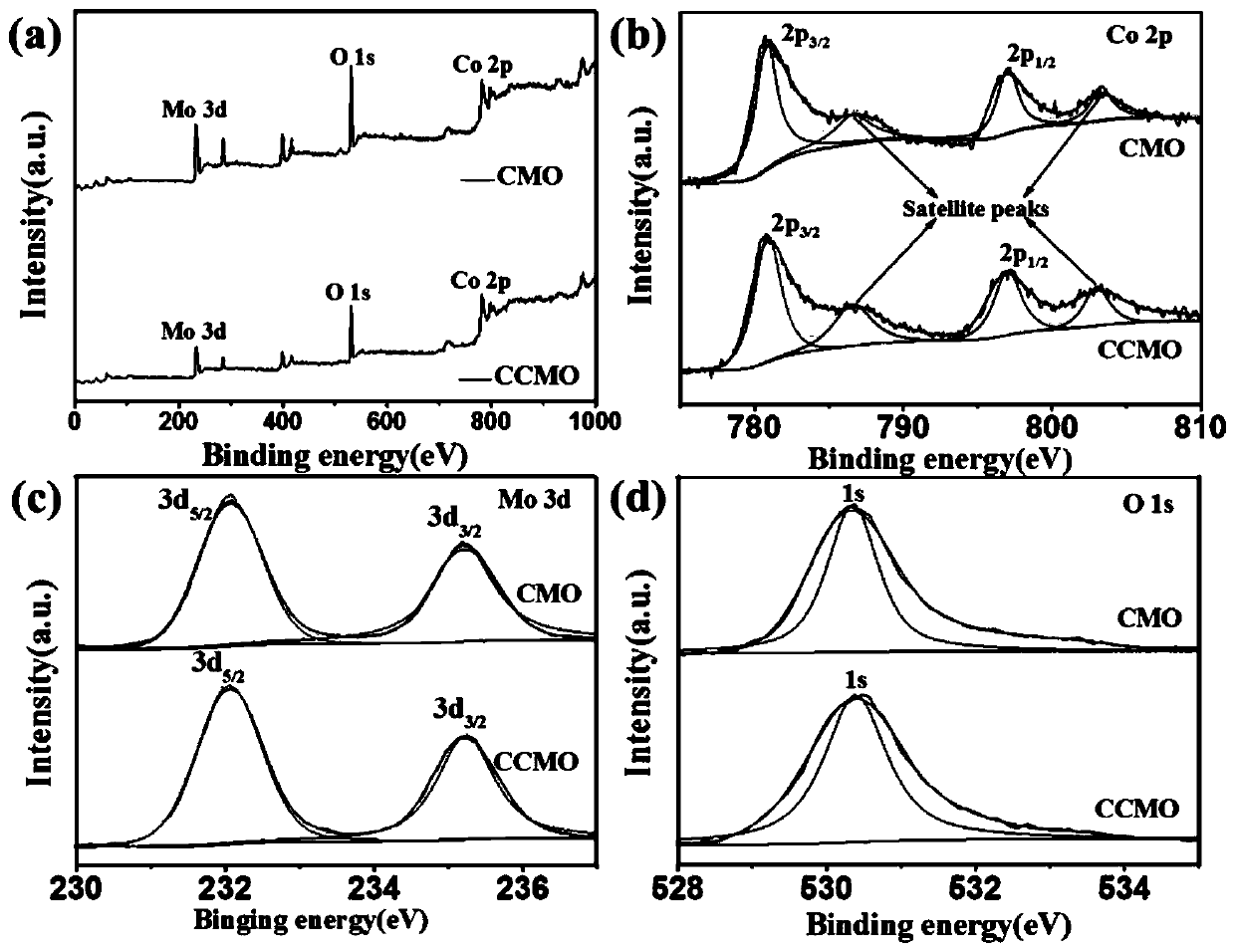

[0027] A kind of CoO / CoMoO described in this embodiment 4 (CCMO) The preparation method of composite material is to make according to the following synthetic steps:

[0028] Dissolve 2mmol cobalt acetate tetrahydrate and 1.5mmol sodium molybdate dihydrate (that is, the Co / Mo molar ratio is 4:3) in 30ml distilled water, and stir for 30min to form a uniform and transparent solution, and then transfer the resulting transparent solution to 50ml In a polytetrafluoroethylene reaction kettle, put the reaction kettle into an oven and heat it to 180°C, then react at a constant temperature for 12 hours, and finally cool to room temperature, wash the obtained precipitated product alternately with deionized water and absolute ethanol for 3 times, centrifugal filter and place in Vacuum drying at 80°C for 12 hours to obtain product 1; then place the obtained product 1 in a tube furnace, control the calcination temperature to 500°C, calcinate in air atmosphere for 3 hours, and finally cool t...

Embodiment 2

[0040] The CoO / CoMoO that above-mentioned embodiment 1 makes respectively 4 Composite material and pure CoMoO prepared in Comparative Example 1 4 The electrochemical performance test of the material is carried out, and the test method is as follows:

[0041] Electrochemical performance tests were evaluated by assembling CR2025 coin cells in an argon-filled glove box. The synthetic material is the active material, PVDF and acetylene black are added to NMP (methylpyrrolidone) at a weight ratio of 8:1:1 and coated on the copper foil (thickness: 100 μm), then placed in a vacuum oven at 80°C for 12h . The copper electrode was cut into small discs with a diameter of 12 mm (mass of active material> 1 mg) as the working electrode of the 2025 coin cell, wherein the counter electrode was lithium, and the diaphragm was Celgard 2300 membrane. The electrolyte is 1mol / L LiPF 6 Dissolve in a mixed solvent of diethyl carbonate / ethylene carbonate / dimethyl carbonate volume ratio of 1:1:1. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com