Micro-socle girder resonator with low temperature cross sensitivity

A technology of micro-cantilever beam and resonator, applied in the field of micro-cantilever beam resonator and cantilever beam resonator, can solve the problems of increasing the complexity and cost of chip structure, packaging and detection system, and not fully satisfying high-precision measurement, etc., to achieve The temperature compensation method is simple and easy, the structure is simple, and the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

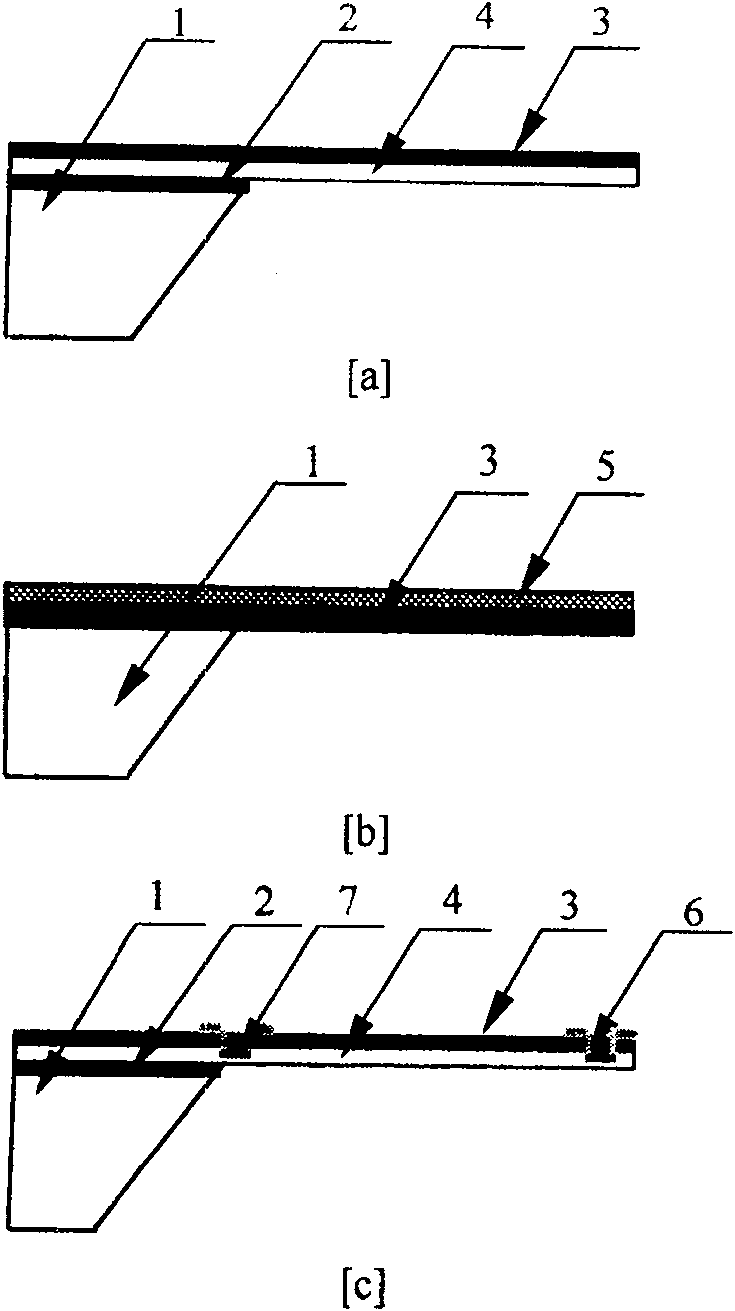

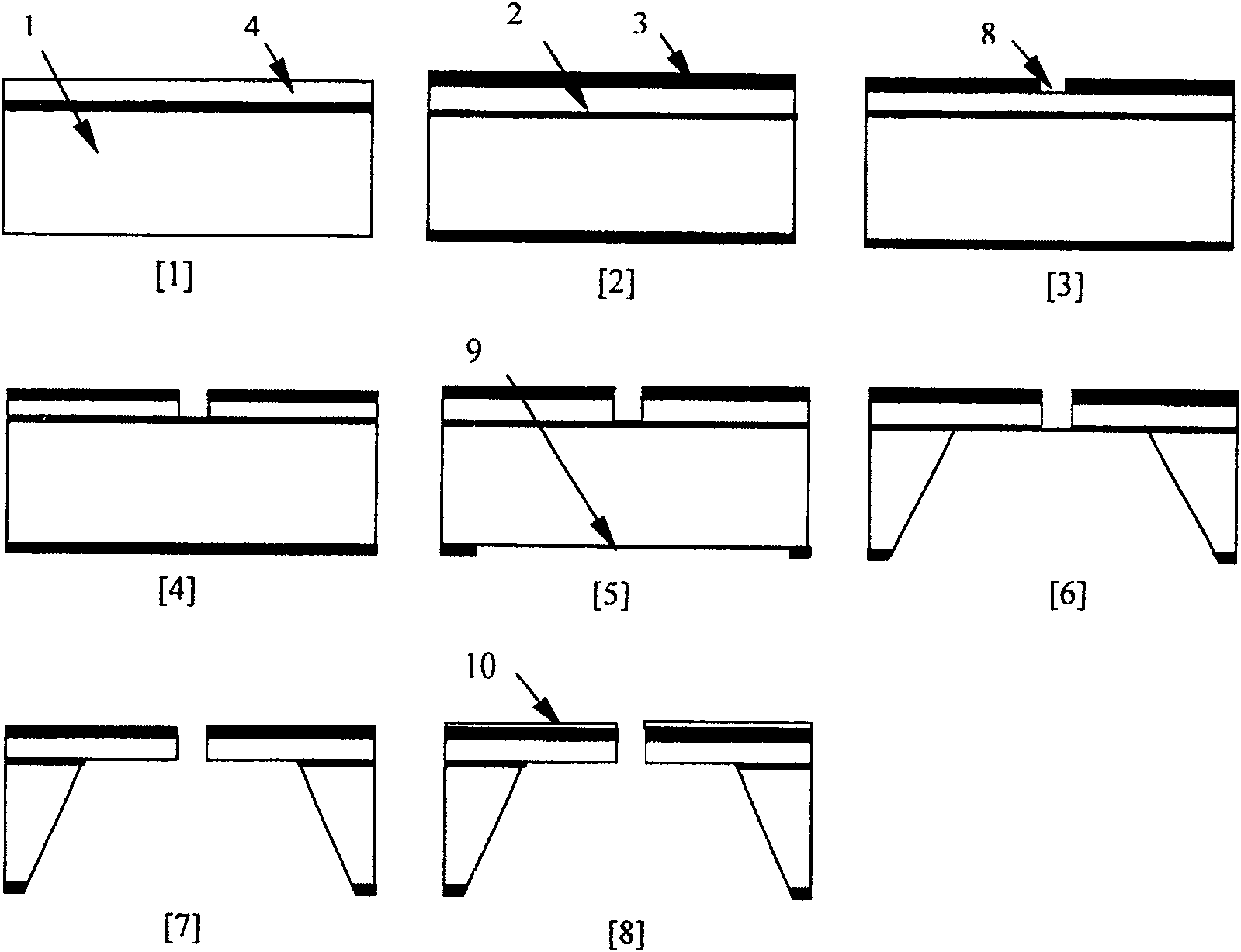

[0022] This embodiment is to manufacture a silicon / silicon dioxide cantilever beam resonator for photothermal excitation / optical signal detection. Among them, the thickness of the silicon layer [4] is 1.3 microns, the thickness of the silicon dioxide layer [3] is 1 micron, and its structure is as attached figure 1 (a) shown. Its production process is as follows (see attached figure 2 ):

[0023] (1) The original silicon wafer is a {100} double-sided polished SOI silicon wafer with a thickness of 400 microns. If the thickness of the silicon dioxide buried layer [2] is t microns, the thickness of the silicon layer [4] should be (1.8+0.45t) microns. (See figure 2 .[1])

[0024] (2) Thermal oxidation, the thickness of the oxide layer [3] is (1+t) microns. (See figure 2 .[2])

[0025] (3) The pattern of the cantilever beam is photolithographically etched on the front, and the silicon dioxide mask in the forming groove [8] around the beam is corroded by slow-release hydro...

Embodiment 2

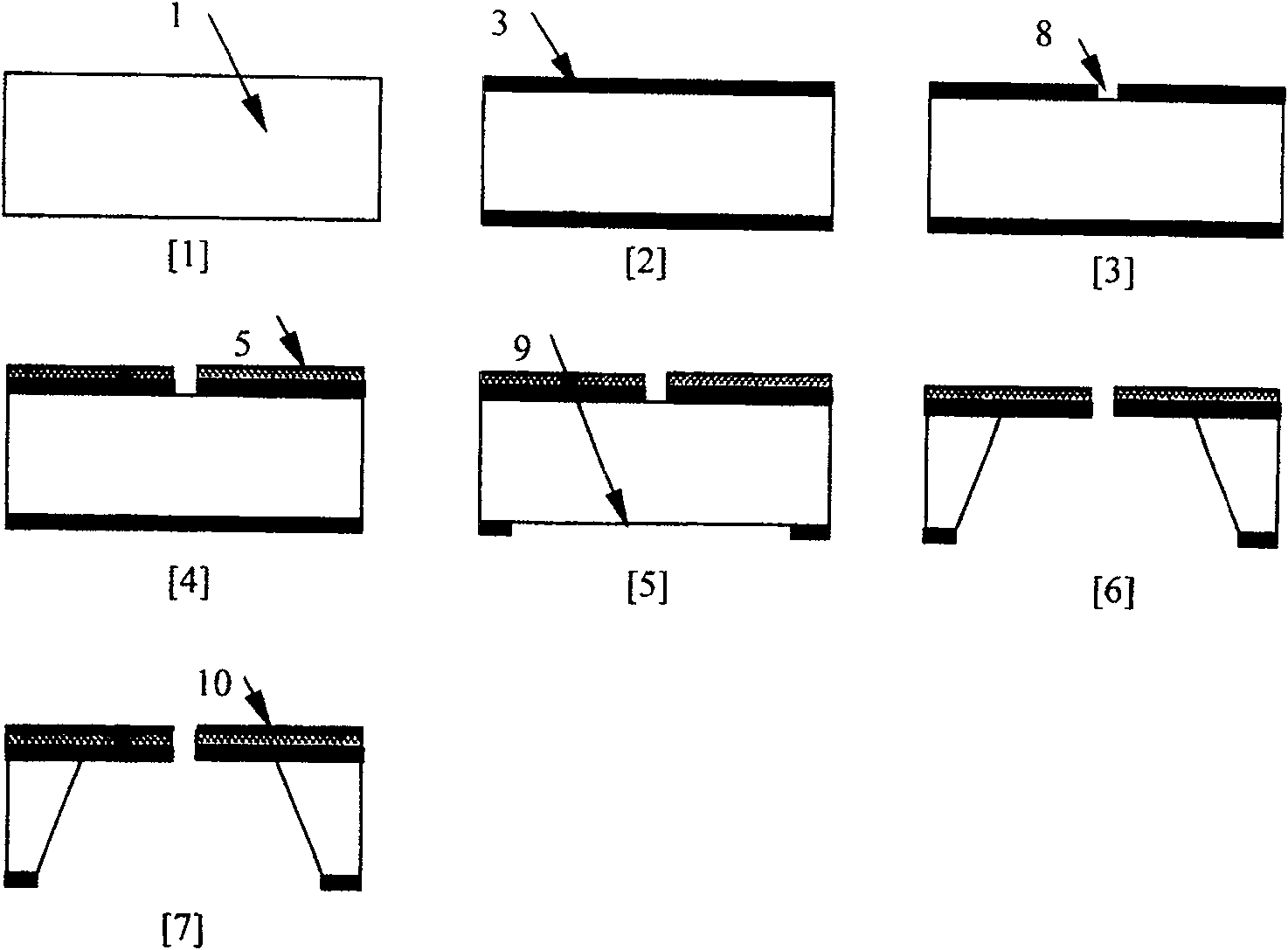

[0032] This embodiment is a silicon dioxide / silicon nitride cantilever beam resonator for photothermal excitation / optical signal detection. Its structure is as attached figure 1 (b) shown. Its production process is as follows (see attached image 3 ):

[0033] (1) The original silicon wafer is an ordinary silicon wafer with {100} plane [1]. (See image 3 .[1])

[0034] (2) thermal oxidation. (See image 3 .[2])

[0035] (3) Photoresist protection on the back side, cantilever beam pattern photolithography on the front side, and slow-release hydrofluoric acid (BOE) corroding the silicon dioxide in the forming groove [8] around the beam. (See image 3 .[3])

[0036](4) LPCVD deposited silicon nitride film [5], the thickness of which is 0.9 to 1.2 times the thickness of the silicon dioxide layer [3]. For backside photoresist protection, use the same mask to etch the cantilever beam pattern on the front side, and etch away the silicon nitride film [5] in the forming groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com