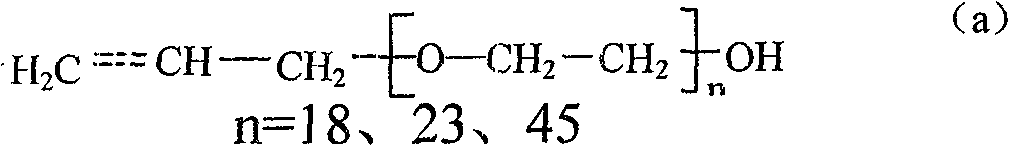

Method for synthesizing allyl polyether-type high-performance water reducing agent

A technology of allyl polyether and synthesis method, which is applied in the field of preparing high-performance concrete water-reducers, can solve the problems of long production cycle, high cost, complicated preparation process of polycarboxylate water-reducers, etc., and achieves simple operation and excellent performance Unaffected, Stable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

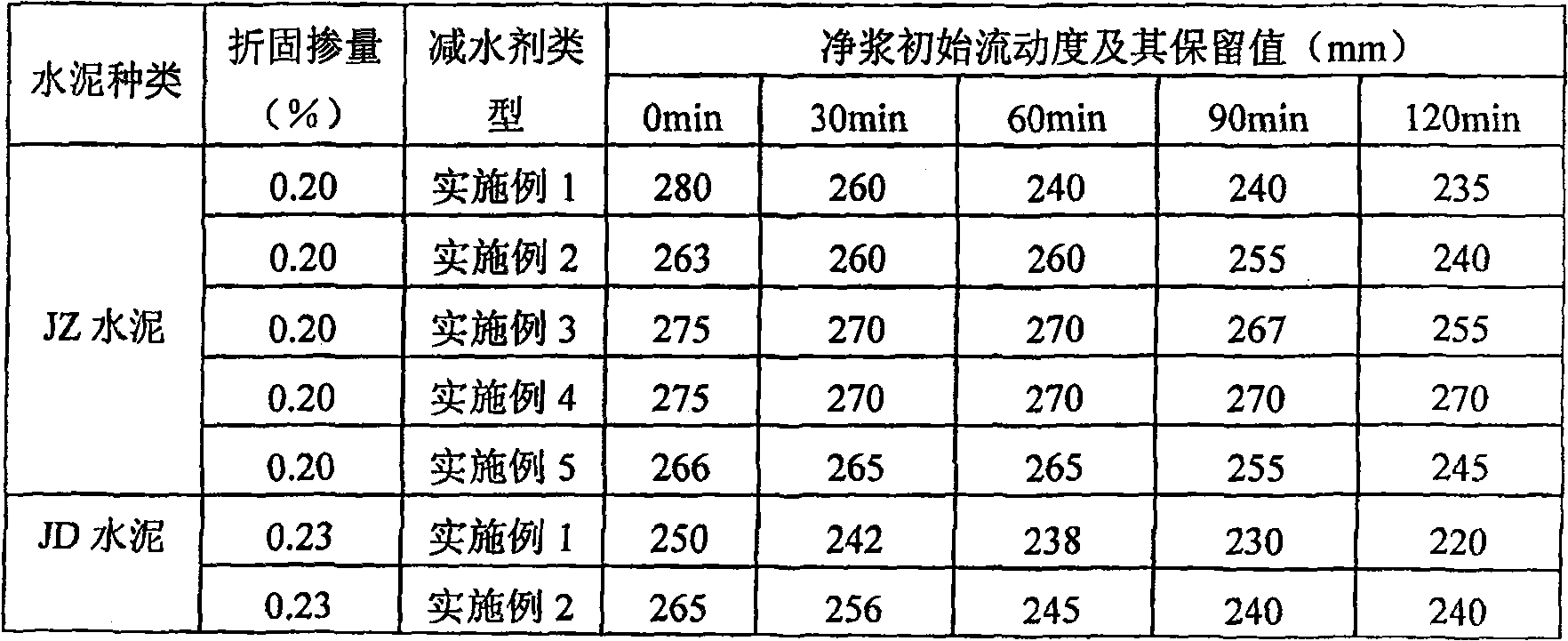

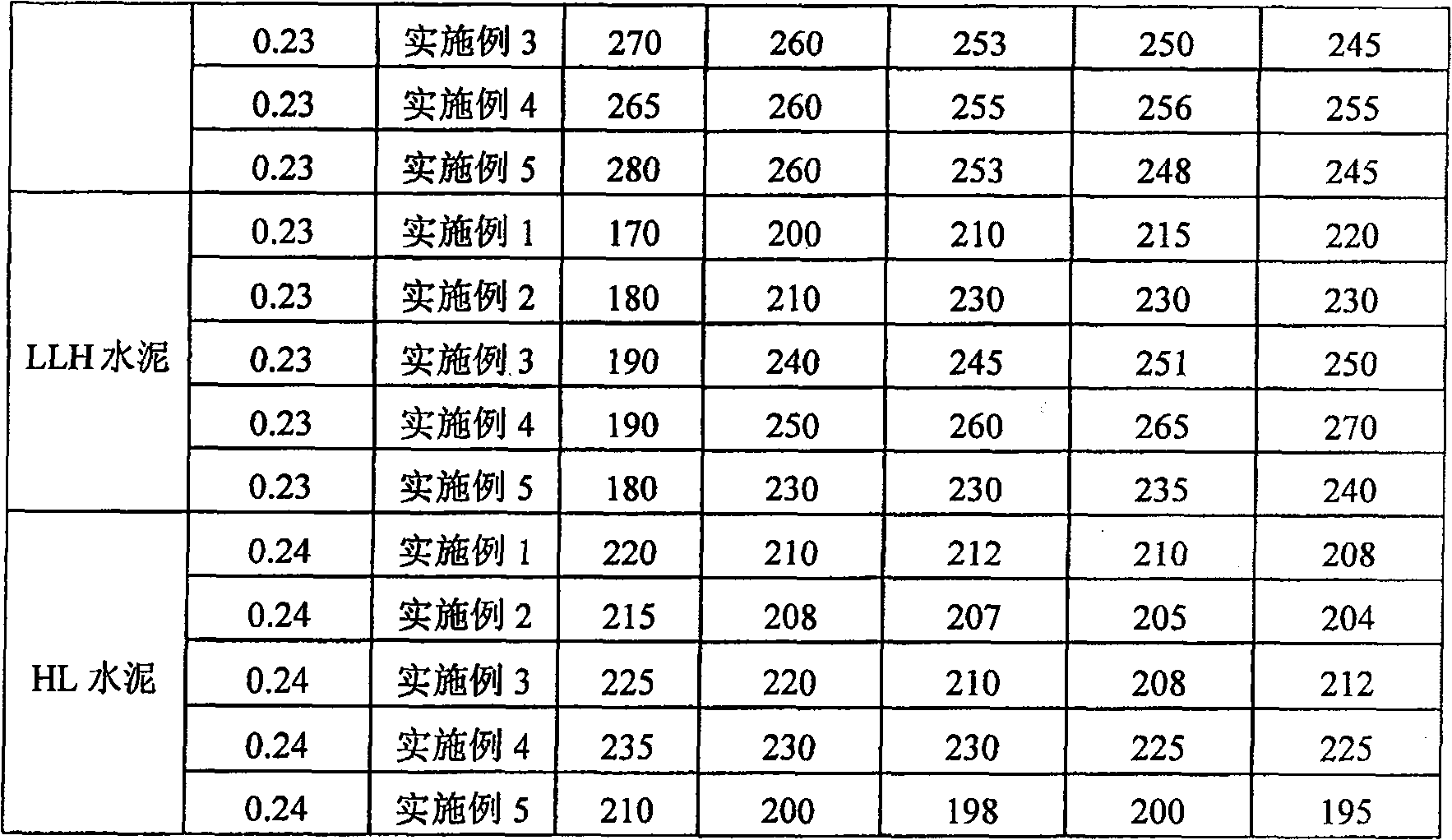

Examples

Embodiment 1

[0026]Add 16 parts of water to the reaction vessel equipped with stirring, condensation, and effluent reflux. When the temperature is at 40°C, add 1.5 parts of maleic anhydride, and add 0.3 parts of sodium hydroxide solution with a mass percentage concentration of 50%. Perform pre-neutralization. Dissolve 0.25 parts of acrylic acid, 0.05 parts of 2-acrylamide-2-methylpropanesulfonic acid, and 1 part of allyl polyethylene glycol ether (n=18) into 25 parts of water in sequence, and stir well to form a light yellow transparent Monomer mixed solution. Dissolve 0.063 parts of ammonium persulfate in 35 parts of water, raise the temperature to 70°C, and add the monomer mixed solution and initiator aqueous solution dropwise, respectively. The monomer mixed solution was added dropwise in 45 minutes, and the initiator aqueous solution was added dropwise in 60 minutes. Keep the blocking reaction at 70°C for 1 hour. Dissolve 0.027 parts of ammonium persulfate into 15 parts of water, st...

Embodiment 2

[0028] Add 13.4 parts of water to the reaction vessel equipped with stirring, condensation, and effluent reflux, add 2 parts of maleic anhydride at a temperature of 45°C, add 1 part of sodium hydroxide solution with a mass percentage concentration of 30%, and pre-neutralize the maleic anhydride. and processing. 1 part of allyl polyglycol ether (n=23) was added. Dissolve 0.15 parts of acrylic acid, 0.15 parts of acrylamide, and 0.05 parts of sodium (meth)allyl sulfonate into 22.3 parts of water, and stir evenly to obtain a transparent solution. Dissolve 0.147 parts of ammonium persulfate in 46.7 parts of water, raise the temperature to 80°C, and add the monomer solution and the aqueous initiator solution dropwise, respectively. The monomer mixed solution was added dropwise in 90 minutes, and the initiator aqueous solution was added dropwise in 90 minutes. Keep at 80°C to block the reaction for 2 hours. Dissolve 0.063 parts of ammonium persulfate into 20 parts of water, stir ...

Embodiment 3

[0030] Add 8.9 parts of water to the reaction vessel equipped with stirring, condensation, and effluent reflux. When the temperature is at 50°C, add 3.5 parts of maleic anhydride, and add 1.2 parts of sodium hydroxide solution with a mass percentage concentration of 50%. Anhydrides are pre-neutralized. Dissolve 0.5 parts of acrylic acid, 0.05 parts of 2-acrylamide-2-methylpropanesulfonic acid, and 1 part of allyl polyglycol ether (n=45) into 15.6 parts of water in sequence, and stir well to form a light yellow transparent Monomer mixed solution. Dissolve 0.13 parts of ammonium persulfate in 31.2 parts of water, raise the temperature to 85°C, and add the monomer mixed solution and initiator aqueous solution dropwise, respectively. The monomer mixed solution was added dropwise in 150 minutes, and the initiator aqueous solution was added dropwise in 180 minutes. Keep the blocking reaction at 85°C for 1 hour. Dissolve 0.06 parts of ammonium persulfate into 13.4 parts of water, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com