Nitrogen-containing ordered mesopore carbon and its synthesis method

A synthesis method and technology of mesoporous carbon, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of cumbersome preparation process and long cycle, and achieve the effects of broad application prospects, low cost, and simple and easy preparation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0045] The preparation of soluble resin precursor solution, 8.00g phenol is put in three-necked flask, 42 ℃ of water-bath heatings, make phenol be transparent liquid, prepare 20% sodium hydroxide solution (take by weighing 0.34gNaOH, add 1.36g distilled water), Slowly drop into the phenol liquid. After 10 minutes, 14.16 g of formaldehyde solution with a mass percentage of 37% was added, refluxed at 70° C. for 1 hour, cooled to room temperature, and adjusted to neutral pH with 2 mol / L hydrochloric acid. Distill under reduced pressure at 45°C to 50°C, cool to room temperature, and prepare 20% ethanol or ether solution.

example 2

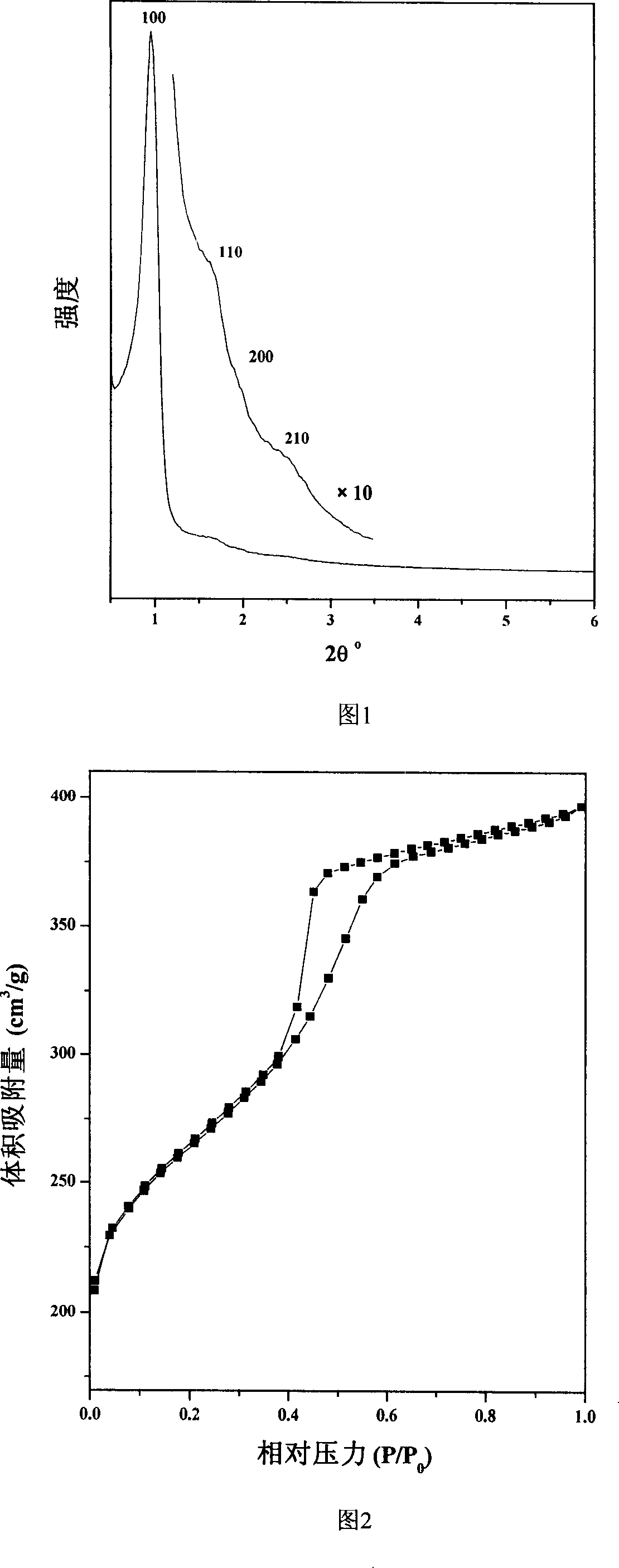

[0047] 0.02 g of m-aminophenol was dissolved in 5.00 g of the soluble resin precursor obtained in Example 1, and the solution A was obtained after stirring for 2 hours. Dissolve 0.61g of F127 in 8.00g of absolute ethanol and stir for 10 minutes to obtain solution B. Mix solutions A and B and stir for 30 minutes. Then spread the mixed solution evenly in a petri dish, leave it at room temperature for 7 hours, and finally transfer it to an oven at 100°C. After 24 hours, the product was baked at 350°C for 5 hours under a nitrogen atmosphere to obtain a nitrogen-containing mesoporous polymer, and then 900 ℃ roasting for 5 hours to obtain nitrogen-containing mesoporous carbon material, as shown in Figure 1, the XRD spectrum proves that the material has a two-dimensional hexagonal structure (space group p6mm), the pore diameter is 4.3nm, and the pore volume is 0.63cm 3 / g, the specific surface area is 1177m 2 / g, its N 2 The adsorption-desorption isotherms belong to type IV (as sh...

example 3

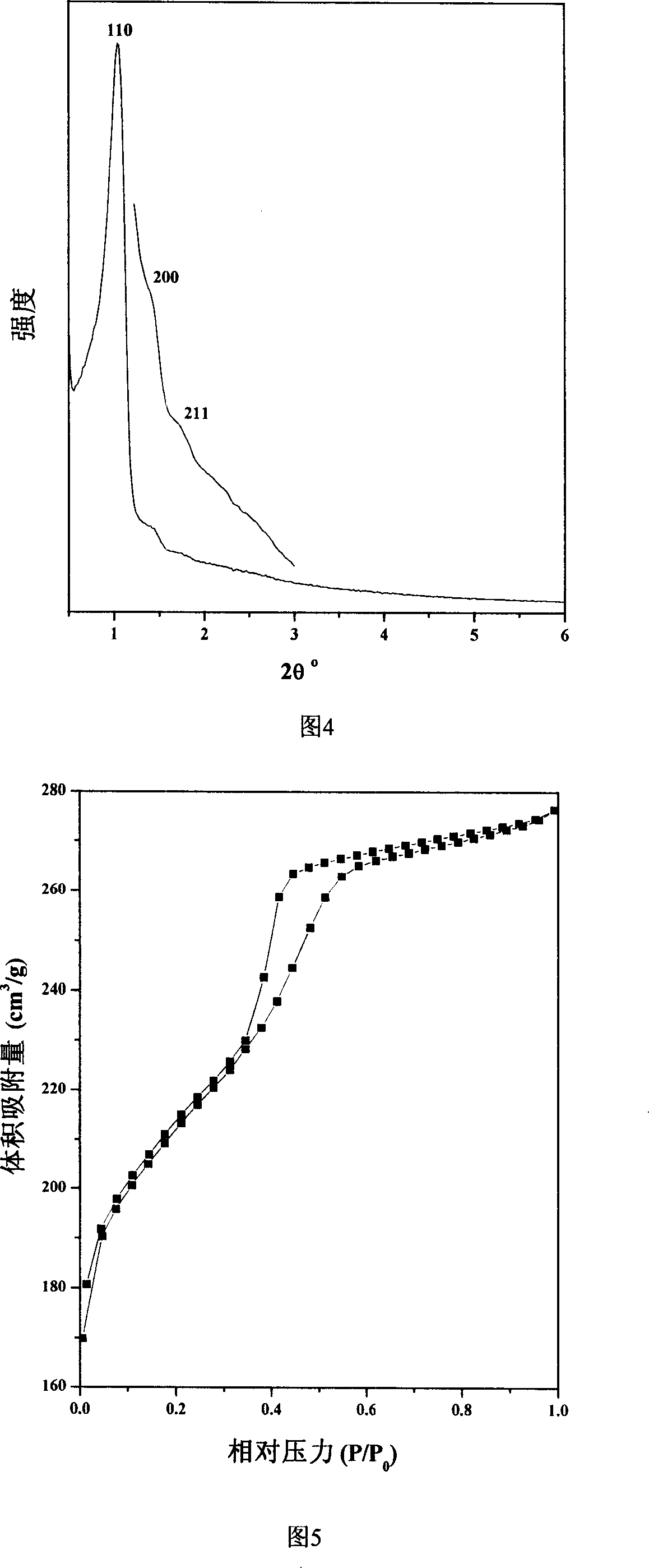

[0049] 0.05g m-aminophenol was dissolved in the ether solution of the soluble resin obtained in 5.00g Example 1, and after stirring for 2 hours, A solution was obtained. Dissolve 0.61g of F127 in 8.00g of ether and stir for 10 minutes to obtain solution B. Mix solutions A and B and stir for 60 minutes. Then spread the mixture evenly in a petri dish, leave it at room temperature for 7 hours, and finally transfer it to an oven at 120°C. After 24 hours, the product is baked at 600°C and 900°C under the protection of nitrogen for 6 hours respectively to obtain nitrogen-containing mesoporous cells. Carbon materials, all have a two-dimensional hexagonal structure (space group p6mm), the pore diameters are 5.2nm and 4.0nm, and the pore volumes are 0.42cm 3 / g and 0.43cm 3 / g, the specific surface area is 705m 2 / g and 890m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com