Method of preparing citronellol

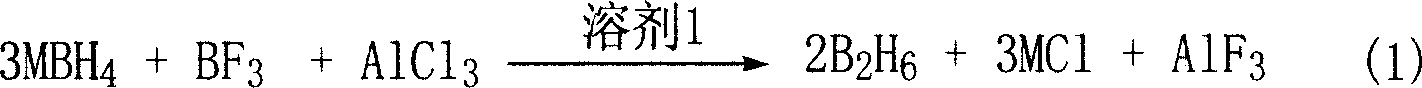

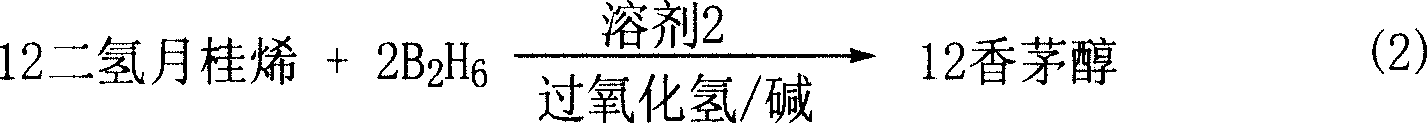

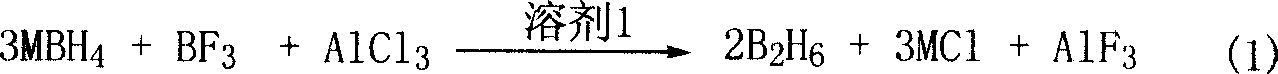

A technology of citronellol and equation, applied in the field of preparing citronellol, can solve the problems of low efficiency of borane, poor selectivity, impossible to realize industrialization and the like, and achieve the effects of high purity, reduced preparation cost and simple process route

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: In a dry three-necked flask equipped with 10ml2.0mol / L boron trifluoride triglyme solution under the protection of a nitrogen atmosphere, 30ml2.0mol / L sodium borohydride triglyme was added dropwise under stirring. Glyme solution and 10ml2.0mol / L aluminum trichloride triglyme solution, the borane produced is introduced into the bottom of the hydroboration reaction bottle through the catheter, and connected to a circular aperture with a diameter of 0.2 The gas disperser of mm is connected, and the drop rate of the reaction liquid is preferably absorbed so that the generated borane can be basically absorbed.

[0030] A mixture of 8 ml of dichloromethane and 25 ml of 85% dihydromyrcene was added to the hydroboration reaction bottle, cooled to 0° C., and the borane produced above was introduced.

[0031] After adding the sodium borohydride solution, after the speed of borane generation slows down, slowly introduce nitrogen gas into the system for 5-20 minutes, put...

Embodiment 2

[0033] Embodiment 2: the difference with Example 1 is that the borohydride used is potassium borohydride, and the end of the bottom gas conduit that imports the borohydrolysis bottle does not have a microporous gas disperser, and the temperature of the borohydride reaction bottle is -14 °C, the reflux time after adding the sodium hydroxide and hydrogen peroxide solution was 2.0 h, and the yield of citronellol was 38%.

Embodiment 3

[0034] Embodiment 3: the difference with Example 1 is that the 2.0mol / L sodium borohydride triglyme solution added in the borane production process is 35ml, and the micropore diameter of the gas disperser used is 0.08mm, in the hydroboration reaction bottle Add a mixed solution of 10ml of dichloromethane and 35ml of 85% dihydromyrcene, the temperature of the hydroboration reaction bottle is -16°C, the reflux time after adding the sodium hydroxide and hydrogen peroxide solution is 2.0h, the citronellol The yield was 87%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com