Method for preparing corrosion resistance rare earth permanent-magnetic material

A rare-earth permanent magnet and corrosion-resistant technology, which is applied in the fields of magnetic materials, inorganic material magnetism, inductor/transformer/magnet manufacturing, etc., can solve the problems of corrosion resistance constraints, easy corrosion, and limited improvement space, and achieve improved corrosion resistance , reduced weight loss, superior corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

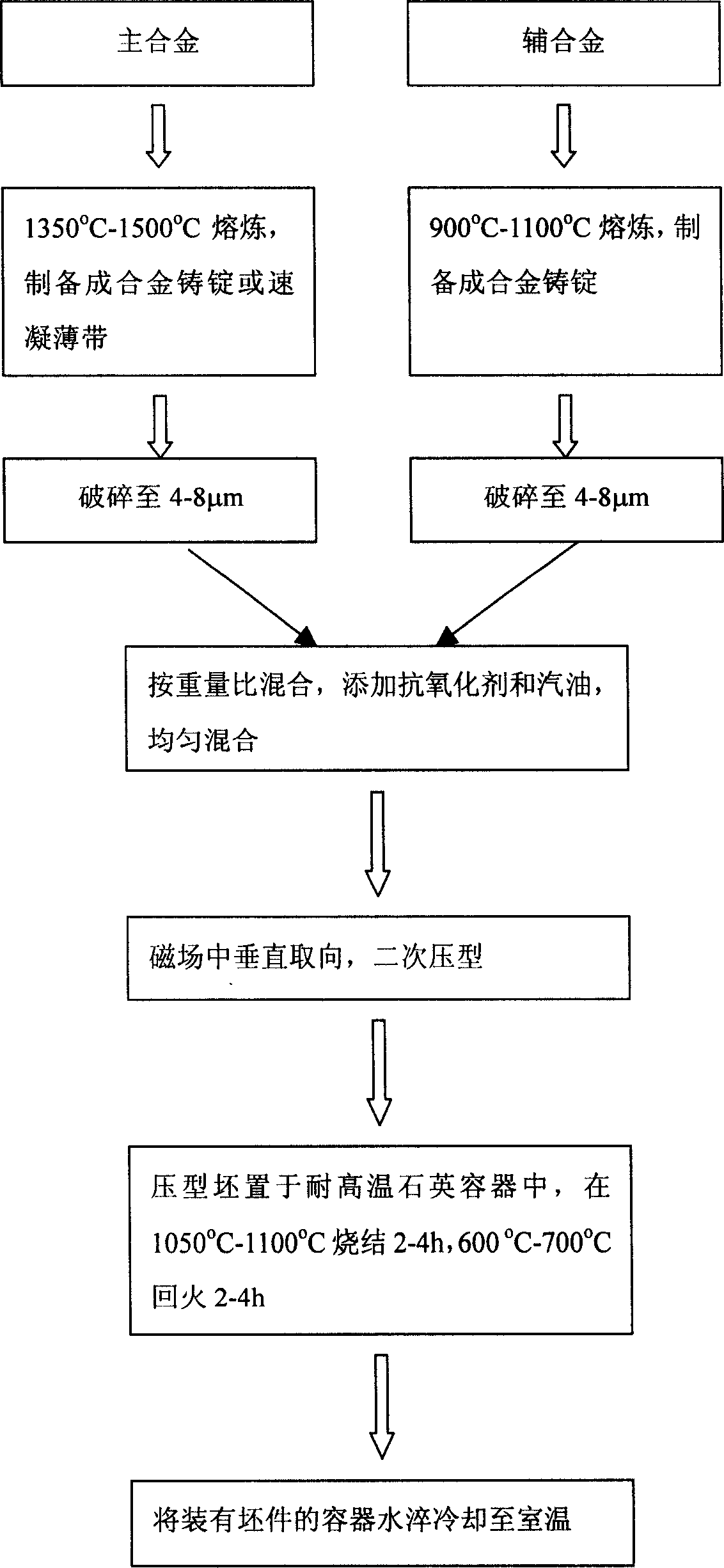

Method used

Image

Examples

Embodiment 1

[0016] 1) Prepare the main and auxiliary alloy ingots respectively, the atomic percentage composition of the main alloy is Nd: 9.5%, Dy: 1.5%,

[0017] Fe: 81.5%, B: 5.5%, Al: 2%, the atomic percentage composition of the auxiliary alloy is Nd: 59.9%, Co:

[0018] 29.9%, Al: 9.9%, Dy: 0.1%, Fe: 0.1%, Cu: 0.1%.

[0019] 2) The main and auxiliary alloys are powdered separately, and the average particle diameter is made by primary and secondary fine crushing under the protection of nitrogen atmosphere.

[0020] It is about 6.5μm powder.

[0021] 3) The main and auxiliary alloy powders are mixed according to the weight ratio of 9:1, and at the same time, 3% of the total weight of the alloy is added.

[0022] Ethylene oxide alkyl ether and 1% gasoline are uniformly mixed into a mixed powder in a mixer.

[0023] 4) The mixed powder is first pressed under a pressure of 8MPa and an orientation magnetic field of 1.7T by a magnetic field orientation forming press

[0024] Forming, an...

Embodiment 2

[0030] 1) Prepare the main and auxiliary alloy ingots respectively. The atomic percentage composition of the main alloy is Nd: 9%, Dy: 1%, Pr: 1%, Tb: 1%, Fe: 78%, Co: 4%, B: 6%, the atomic percentage composition of the auxiliary alloy is Nd: 30%, Pr: 10%, Dy: 10%, Co: 29.9%, Fe: 0.1%, Al: 10%, Cu: 5%, Ga: 5%.

[0031] 2) Powder the main and auxiliary alloys separately. Through primary and secondary fine crushing under the protection of nitrogen atmosphere, powder with an average particle diameter of about 6.5 μm is produced.

[0032] 3) The main and auxiliary alloy powders are mixed according to the weight ratio of 9:1, and the antioxidant polyethylene oxide alkyl ether accounting for 3% of the total weight of the alloy powder and the gasoline accounting for 1% of the total weight of the alloy powder are added at the same time. Mix evenly into a mixed powder.

[0033] 4) The mixed powder is first pressed and formed by a magnetic field orientation forming press under a press...

Embodiment 3

[0037] 1) Prepare the main and auxiliary alloy ingots respectively. The atomic percentage composition of the main alloy is Nd: 7%, Dy: 3%, Tb: 2%, Fe: 78%, Co: 4%, B: 6%, and the auxiliary alloy The atomic percent composition is Nd: 40%, Pr: 15%, Fe: 5%, Co: 25%, Al: 10%, Cu: 2%, Ga: 2%, Nb: 1%.

[0038] 2) Powder the main and auxiliary alloys separately. Through primary and secondary fine crushing under the protection of nitrogen atmosphere, powder with an average particle diameter of about 5.5 μm is produced.

[0039] 3) The main and auxiliary alloy powders are mixed according to the weight ratio of 88:12, and the antioxidant polyethylene oxide alkyl ether accounting for 3% of the total weight of the alloy powder and the gasoline accounting for 1% of the total weight of the alloy powder are added at the same time. Mix evenly into a mixed powder.

[0040] 4) The mixed powder is first pressed and formed by a magnetic field orientation forming press under a pressure of 8 MPa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com