Substance and method for splitting induced dry-cell to cartilage

A stem cell differentiation and stem cell technology, which is applied in the fields of medicine and biomedical engineering, can solve the problems of disease transmission and insufficient source of autologous chondrocytes, and achieve the effect of sufficient source, easy large-scale promotion and application, and easy acquisition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0078] The preparation method of inducer

[0079] Separating (such as filtering or centrifuging) the culture solution obtained by culturing chondrocytes or cartilage tissues in vitro to remove the chondrocytes and cartilage tissues, so as to obtain a solution free of cells and cell debris.

[0080] A preferred method is to separate the culture fluid obtained by culturing chondrocytes or cartilage tissues in vitro by centrifugation to remove the chondrocytes and cartilage tissues, thereby obtaining a filtrate free of cells and cell debris.

[0081] The culture medium is the culture medium obtained during culturing chondrocytes or cartilage tissues for 1-200 days; more preferably, the time for culturing chondrocytes is 1 day-90 days, and the time for cultivating tissue-engineered cartilage constructed by chondrocytes is 3 days - 180 days.

[0082] The culture fluid is the culture fluid obtained during 24 hours to 150 hours after the liquid change; more preferably, when the cult...

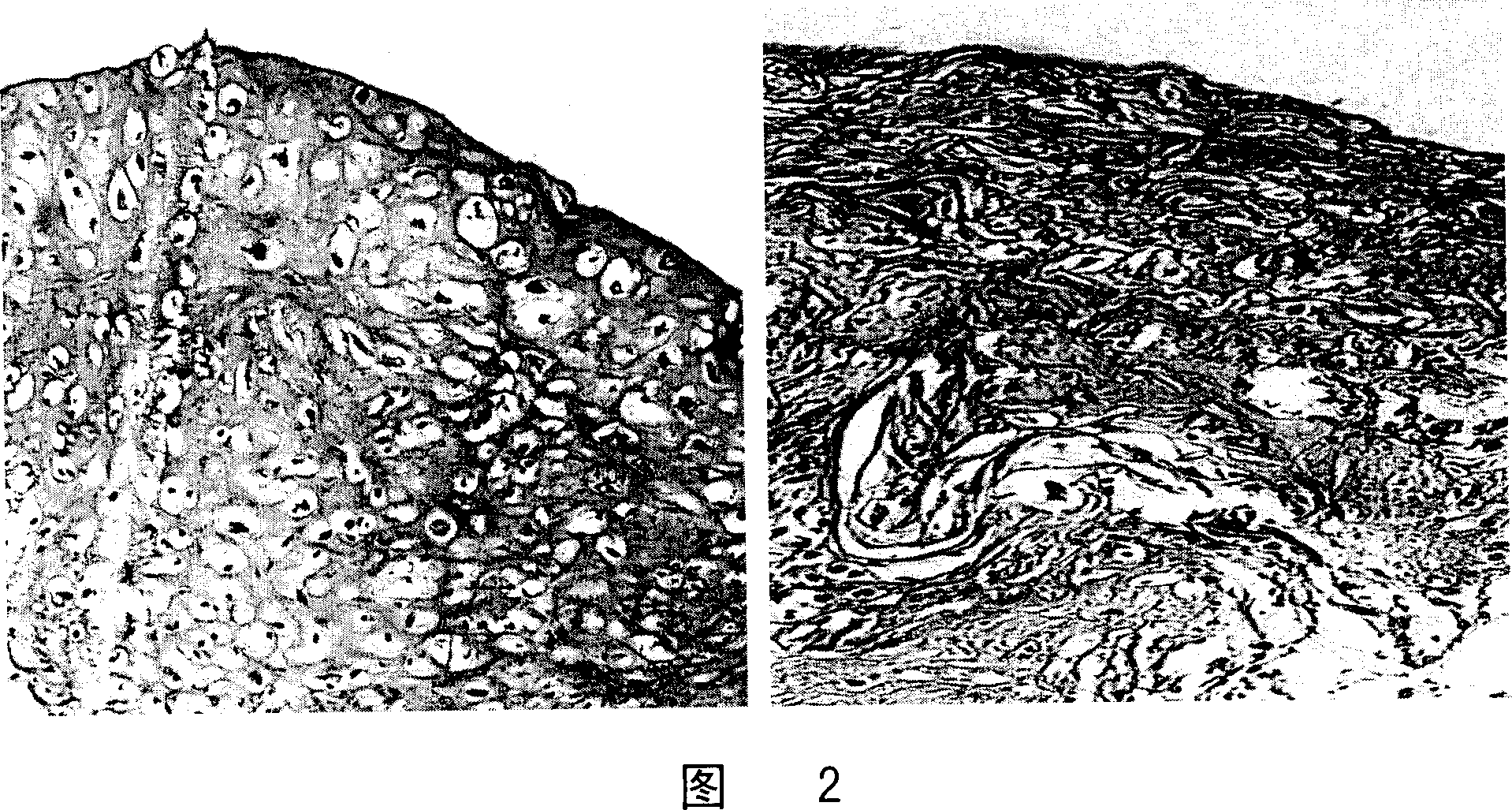

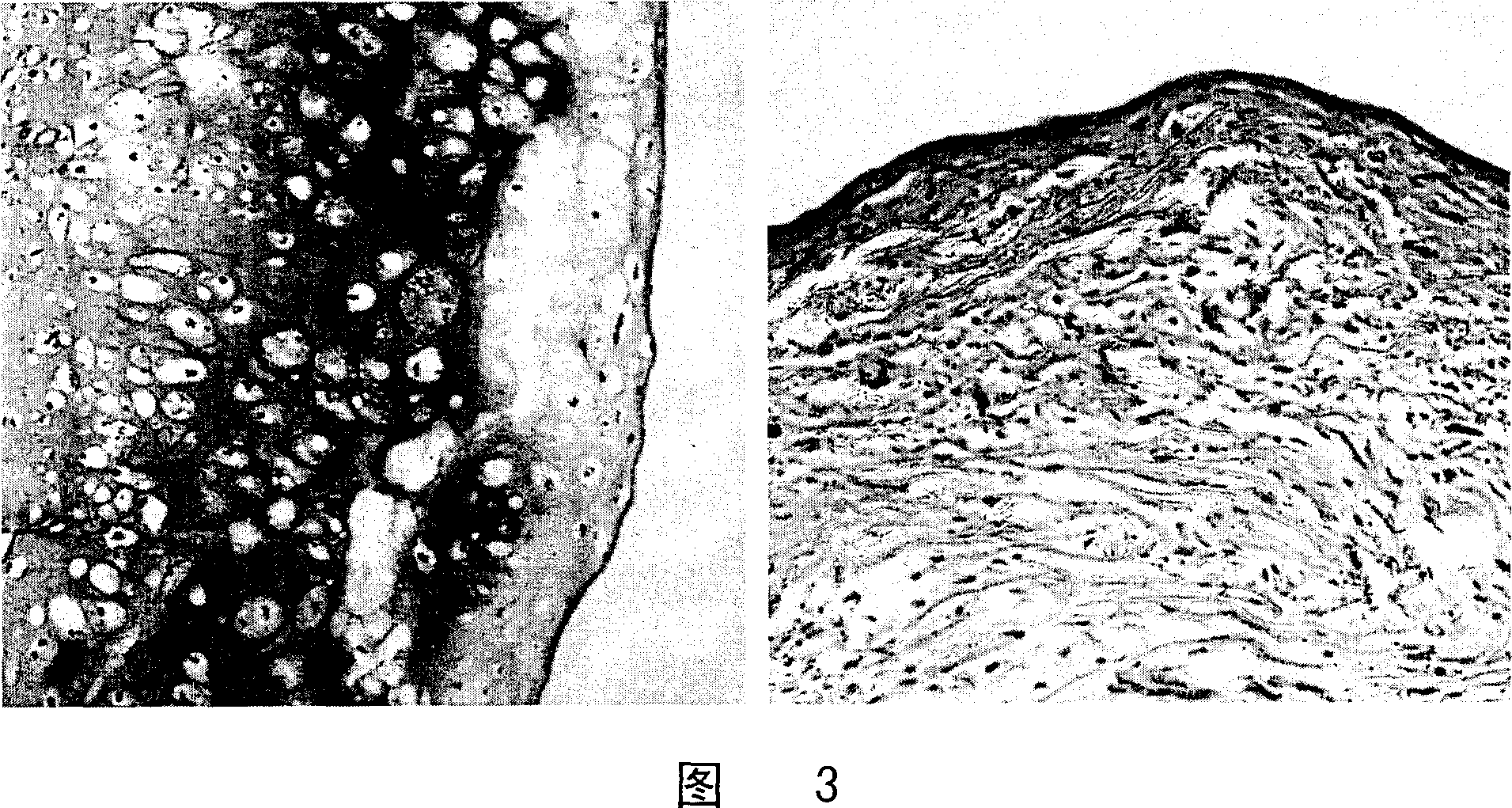

Embodiment 1

[0109] Preparation of inducer I for inducing stem cells to differentiate into cartilage

[0110] 1. Isolation and culture of chondrocytes

[0111] Experimental animals:

[0112] 5 young pigs, weighing about 10kg, male or female.

[0113] experimental method:

[0114] 1. Animals were anesthetized with ketamine 10-20 mg / kg and atropine 0.5-1 mg intramuscularly to induce and inhibit glandular secretion, and slowly push 1 ml / kg of chloral hydrate (10%) or sodium pentobarbital ( 2.5%) 1ml / kg anesthetized;

[0115]2. Routinely disinfect the drape, aseptically cut the knee articular cartilage tissue, cut it into 2mm×3mm pieces, and wash it twice with phosphate buffer;

[0116] 3. According to the modified Klagsbrun method, add 5 times the volume of 1 mg / ml type II collagenase (Worthington, Freehold, NJ, USA), place it in a constant temperature shaker at 37°C for 8-12 hours, filter, and centrifuge;

[0117] 4. The precipitated cells were washed twice with PBS, and the cell suspen...

Embodiment 2

[0125] Preparation of Inducer II for Inducing Stem Cell Differentiation to Cartilage

[0126] 1. Chondrocyte-material composite construction

[0127] (1) Preparation of polyglycolic acid (PGA) three-dimensional scaffold

[0128] Non-woven PGA fibers were purchased from Albany Company (Albany, NY, USA) and stored in vacuum. The fiber diameter is 13-15μm, and the PGA fiber is accurately weighed to 20mg / piece, and is pressed into small cylindrical pieces with a diameter of 13mm and a thickness of 2mm with a special mold. After the shape is fixed, the material support is completely immersed in 75% ethanol Disinfect for 30 minutes. Rinse with PBS 3 times, then soak in DMEM medium containing 10% fetal bovine serum for 10 minutes, blot dry and prepare to inoculate cells.

[0129] (2) Construction of chondrocyte-material complex

[0130] 1. When the first-generation chondrocytes cultured in monolayer reached 90% confluence, they were digested with 0.25% trypsin + 0.02% EDTA, colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com