Method of inhibiting hydrochloric acid from generating during recycling of waste plastic

A technology of recycling and waste plastics, applied in plastic recycling, products, reagents, etc., can solve the problems of loss of stabilizer, rust of manufacturing machinery, etc., to reduce storage area, improve mechanical strength, and achieve the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Hereinafter, an embodiment of the present invention having the above configuration will be described. The evaluation of the acidity test was performed as follows.

[0039] Magnesium oxide (MgO ) 1% by weight, 0.1% by weight, and 0.01% by weight were mixed with a drum to prepare three kinds of sample materials. In addition, CD and polypropylene (PP) without adding an acid acceptor were prepared as comparative materials. Next, each of the aforementioned sample materials and comparative materials was molded at 220° C. using a 50 t injection molding machine to prepare five types of test samples.

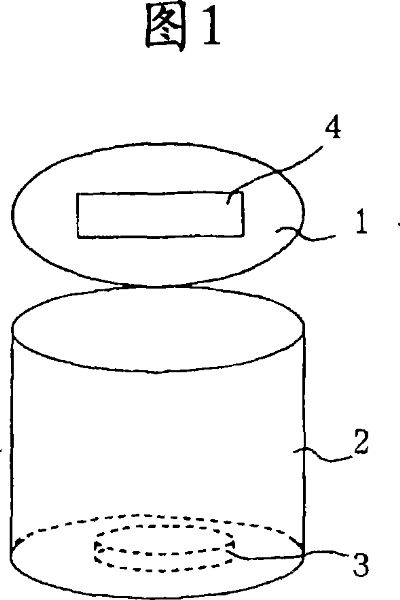

[0040] The acidity of the above samples was measured. As shown in FIG. 1 , for a can body 2 with an opening and closing lid 1 , the aforementioned injected sample 3 was immediately put into the can body 2 , the lid 1 was closed, and left at room temperature for more than 8 hours. A reagent 4 for measuring pH such as litmus paper is pasted on the inside of the aforementioned co...

Embodiment 2

[0045] Hereinafter, in order to measure the acidity more accurately, a case where ion chromatography is used will be described. The acid acceptor is generally in the form of a powder. Therefore, various powders of magnesium oxide, hydrotalcite, calcium carbonate, magnesium carbonate, calcium hydroxide, and magnesium silicate are used as the acid acceptor.

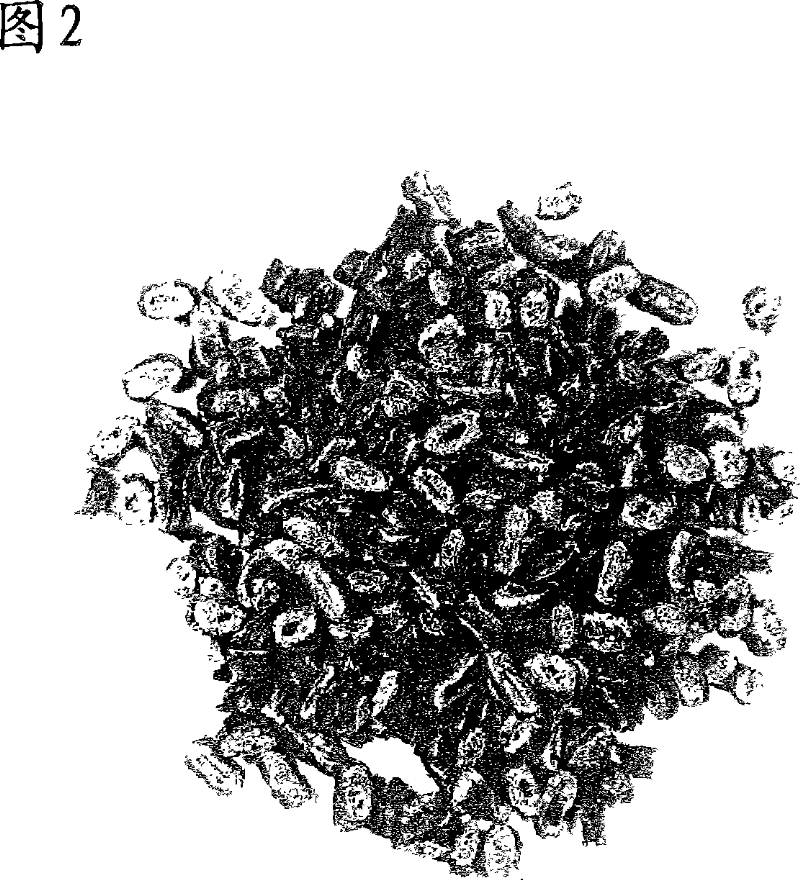

[0046] However, when tumble mixing is performed in a powder state, the dispersibility is poor due to high powder aggregation. In addition, the bulk specific gravity of the powder is small and the volume is large, so it is not good for recycling plastic materials. CDs are mixed with various materials such as low-density polyethylene (LDPE), polypropylene (PP), polyethylene terephthalate (PET), nylon, and polyvinyl chloride (PVC).

[0047] That is, materials with different melting points are mixed in the CD. PVC is included in these mixed materials, and PVC is considered to be the cause of hydrochloric acid generation. Co...

Embodiment 3

[0066] In embodiment 3, adopt correct method to carry out the mensuration of hydrochloric acid again. In this example, evaluation was performed on the case of using magnesia powder and hydrotalcite powder alone as the acid acceptor and the case of using them in combination.

[0067] (Evaluation sample preparation method)

[0068] First, as the raw material before granulation, the loose matter was washed, centrifugally dehydrated, and dried in a drying oven at 50°C for 10 minutes, 20 minutes, and 30 minutes. As the acid acceptor, magnesia powder, hydrotalcite powder or a mixture thereof were used alone, and the base resin was made of low-density polyethylene (LDPE) as a masterbatch.

[0069] (test methods)

[0070] The aforementioned dried raw materials were put into a twin-screw extruder (diameter 50 mm, co-rotating twin-screw type, L / D-28), and the concentration of hydrochloric acid in the gas generated at the extrusion outlet was measured. The barrel temperature of the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com