Hydrogen storage material of coordinated alanate, and preparation method

A technology for hydrogen storage material and aluminum hydride, which is applied in the field of preparation of hydrogen storage material, can solve problems such as capacity loss and harm, and achieve the effects of reducing particles, avoiding impurity gas pollution, and reducing dispersed catalysts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

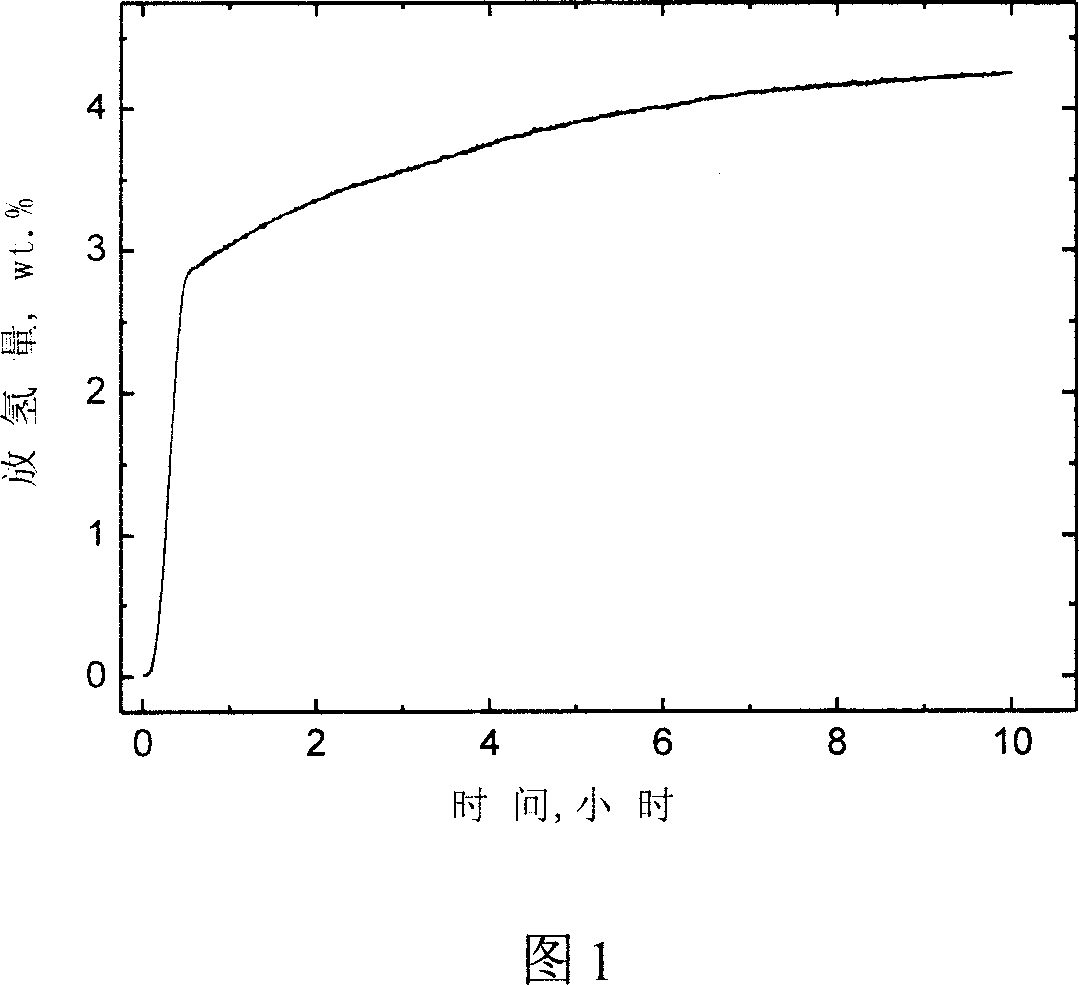

[0034] Preparation of Ti-doped NaAlH with NaH and Al powders as matrix and Ti powder as dopant 4 Hydrogen storage material.

[0035] The raw materials used are: NaH (purity 95%, ~200 mesh), Al powder (purity greater than 99.95%, ~200 mesh), and Ti powder (purity 99.98%, ~325 mesh). Raw materials are used directly without treatment. In an argon atmosphere glove box, first put the raw material mixture in the molar ratio of NaH+0.04Ti into a stainless steel ball mill jar, and grind it on a Fritsch 7 planetary ball mill for 10 hours. The average catalyst grain size is about 500 nanometers. The ball milling atmosphere is high-purity hydrogen (purity 99.999%), and the initial pressure is about 8 atmospheres. The ball to material (mass) ratio is 40:1. Then open the stainless steel ball mill tank in the glove box, add Al powder (molar ratio NaH:Al=1:1) and ball mill for another 10 hours under the same conditions, the average particle size of the matrix material is less than 1 micro...

Embodiment 2

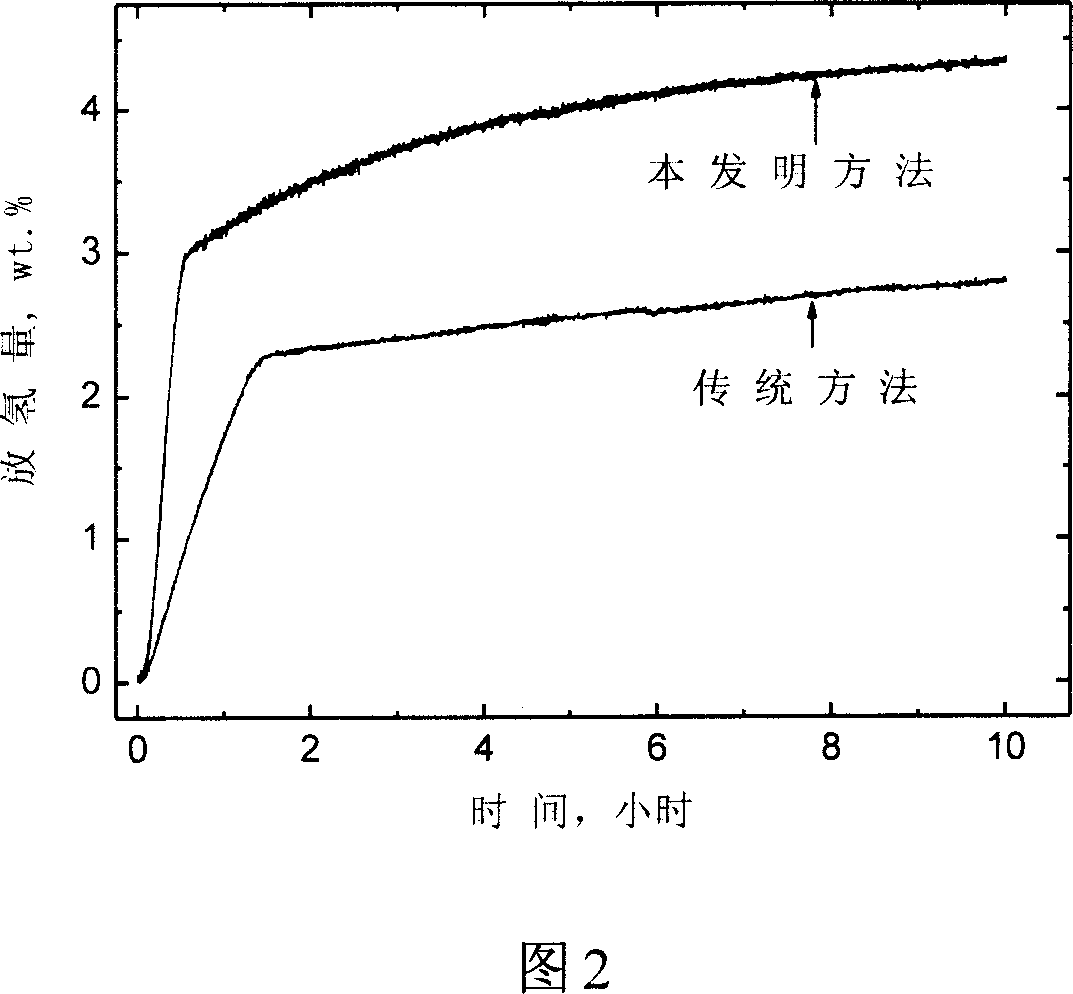

[0039]Preparation of Ti-doped NaAlH with NaH and Al powders as matrix and Ti powder as dopant 4 Hydrogen storage material.

[0040] The raw materials used are: NaH (purity 95%, ~200 mesh), Al powder (purity greater than 99.95%, ~200 mesh), and Ti powder (purity 99.98%, ~325 mesh). Raw materials are used directly without treatment. In an argon atmosphere glove box, first put the raw material mixture in the molar ratio of NaH+0.04Ti into a stainless steel ball mill jar, and grind it on a Fritsch 7 planetary ball mill for 10 hours. The average catalyst grain size is about 500 nanometers. The ball milling atmosphere is Ar atmosphere. The ball-to-material ratio is 40:1. Then open the stainless steel ball mill tank in the glove box, add Al powder (NaH:Al=1:1) and ball mill for another 10 hours under the same conditions, the average particle size of the matrix material is less than 1 micron.

[0041] In order to compare with the material prepared by the traditional direct synthes...

Embodiment 3

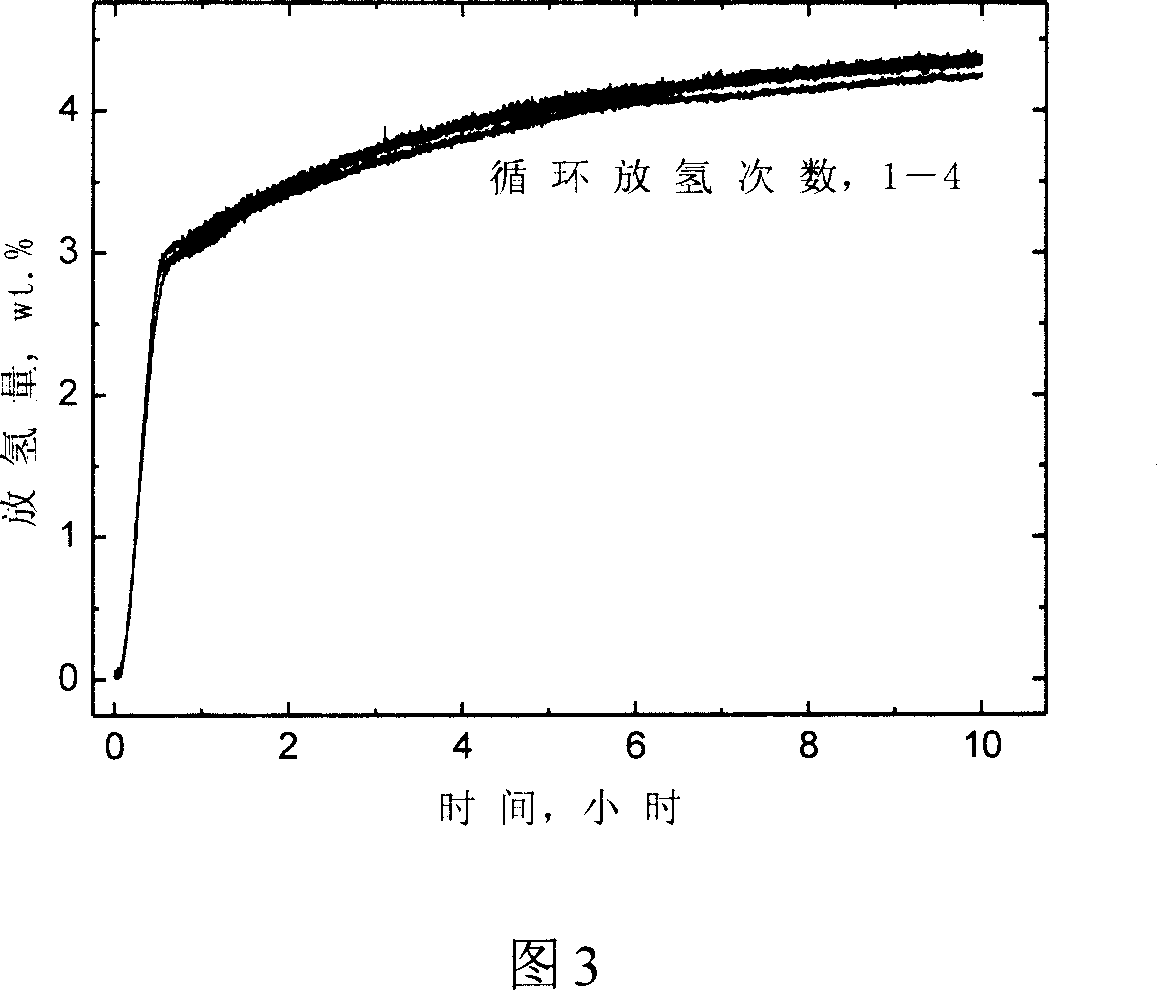

[0046] With NaH, Al powder as the matrix, TiH 2 Preparation of Ti-doped NaAlH as a dopant 4 Hydrogen storage material.

[0047] The raw materials used are: NaH (purity 95%, ~200 mesh), Al powder (purity greater than 99.95%, ~200 mesh), and TiH 2 powder (98% purity, ~325 mesh). Raw materials are used directly without treatment. Put molar ratio NaH+0.04TiH in the argon atmosphere glove box 2 The proportioned raw material mixture was put into a stainless steel ball mill jar, and ground on a Fritsch 7 planetary ball mill for 10 hours, and the average catalyst grain size was about 500 nanometers. The ball milling atmosphere is Ar atmosphere. The ball-to-material ratio is 40:1. Then open the stainless steel ball mill tank in the glove box, add Al powder (NaH:Al=1:1) and ball mill for another 10 hours under the same conditions, the average particle size of the matrix material is less than 1 micron.

[0048] The hydrogen absorption and desorption properties of the materials wer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com