Method for preparing Nano zinc oxide film with different appearances through solution technique

A zinc oxide thin film, solution method technology, applied in zinc oxide/zinc hydroxide, nanotechnology, nanotechnology and other directions, can solve the problems of high temperature requirements, poor controllability, high cost, unsuitable for large-scale production, etc. Good orientation, low cost and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] (1) 0.025mol / L of Zn(NO 3 ) 2 and 0.025mol / L (CH 2 ) 6 N 4 The solutions are mixed in equimolar numbers, and the pH value of the solution is adjusted with nitric acid to make pH=2.6, and fully stirred;

[0022] (2) Put the conductive glass with the zinc oxide seed bottom obtained by thermal decomposition face down into the above solution, heat to 85° C., reflux, keep the temperature at constant temperature for 6 hours, and then cool naturally.

[0023] (3) The substrate was taken out, rinsed with distilled water, and dried in an oven at 60° C. for 1 hour.

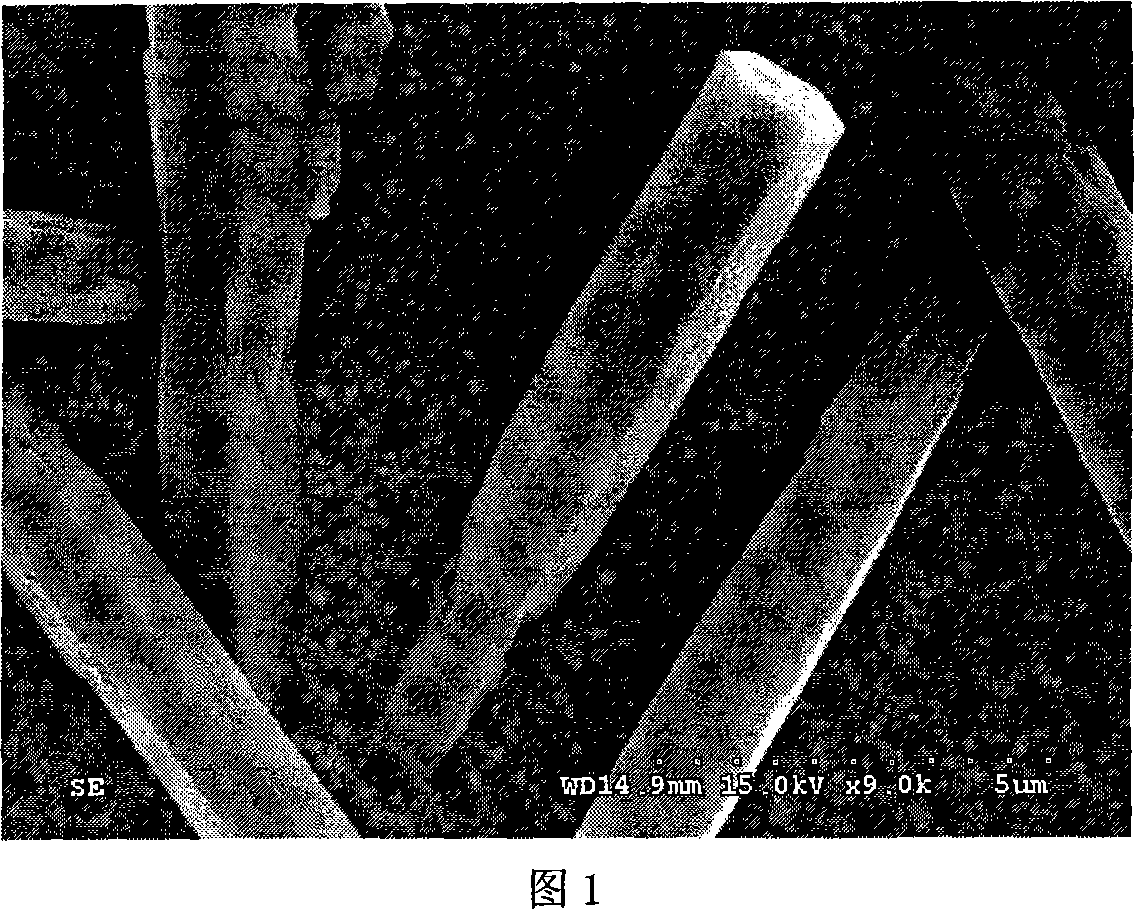

[0024] A pencil-like one-dimensional ZnO rod with a diameter of about 1.8 μm and a length of 10 μm was obtained.

Embodiment 2

[0026] 1) Add 0.025mol / L of Zn(NO 3 ) 2 and 0.025mol / L (CH 2 ) 6 N 4 The solutions are mixed in equimolar numbers, and the pH value of the solution is adjusted with hydrochloric acid to make pH=2.62, and fully stirred;

[0027] (2) Put the conductive glass with the zinc oxide seed bottom obtained by thermal decomposition face down into the above solution, heat to 90°C, reflux and keep the temperature for 6 hours, then cool naturally;

[0028] (3) The substrate was taken out, rinsed with distilled water, and dried in an oven at 60° C. for 1.5 hours.

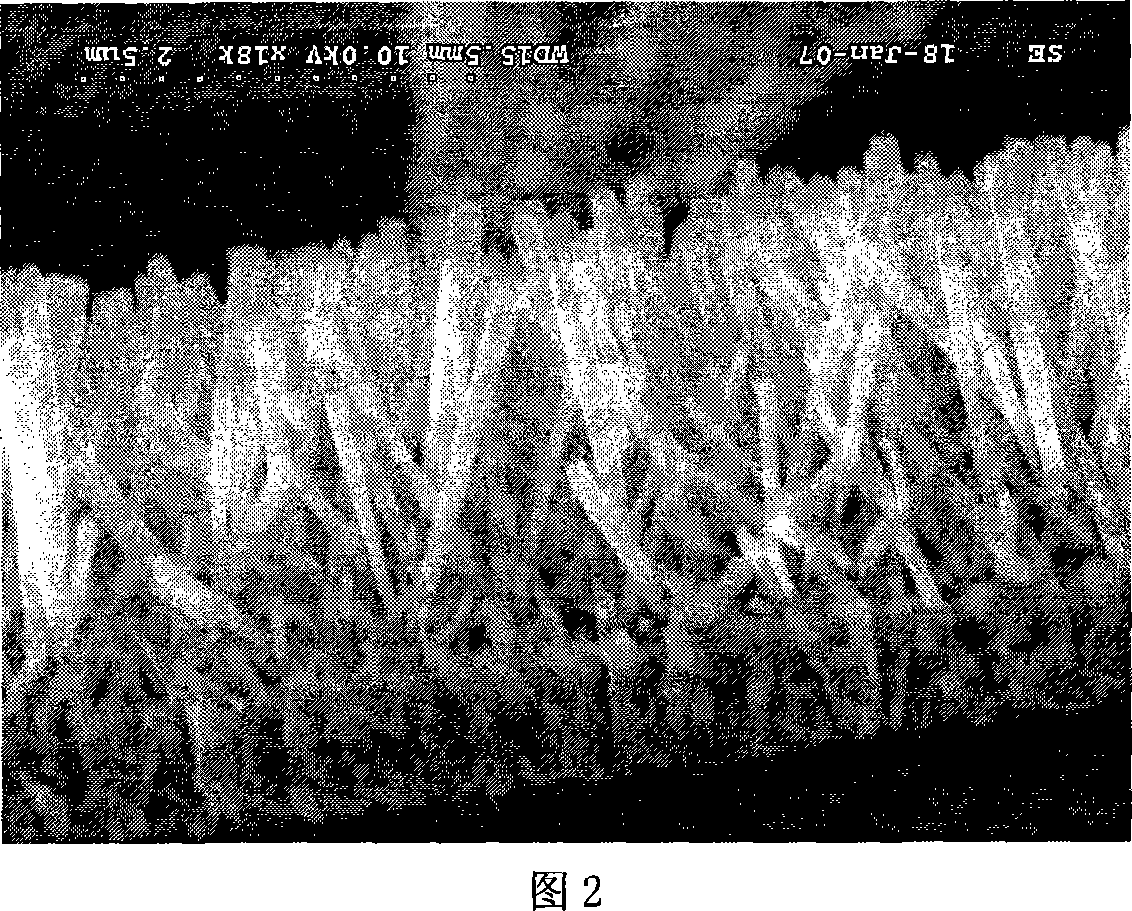

[0029] Hexagonal one-dimensional zinc oxide with a diameter of 2.5 μm and a length of 5 μm was prepared.

Embodiment 3

[0031] (1) 0.025mol / L of Zn(NO 3 ) 2 and 0.025mol / L (CH 2 ) 6 N 4 The solutions are mixed in equimolar numbers, and the pH value of the solution is adjusted with hydrochloric acid to make pH=4, and fully stirred;

[0032] (2) Put the conductive glass with the zinc oxide seed bottom obtained by thermal decomposition face down into the above solution, heat to 88°C, reflux and keep the temperature for 6 hours, then cool naturally;

[0033] (3) The substrate was taken out, rinsed with distilled water, and dried in an oven at 60° C. for 1 hour.

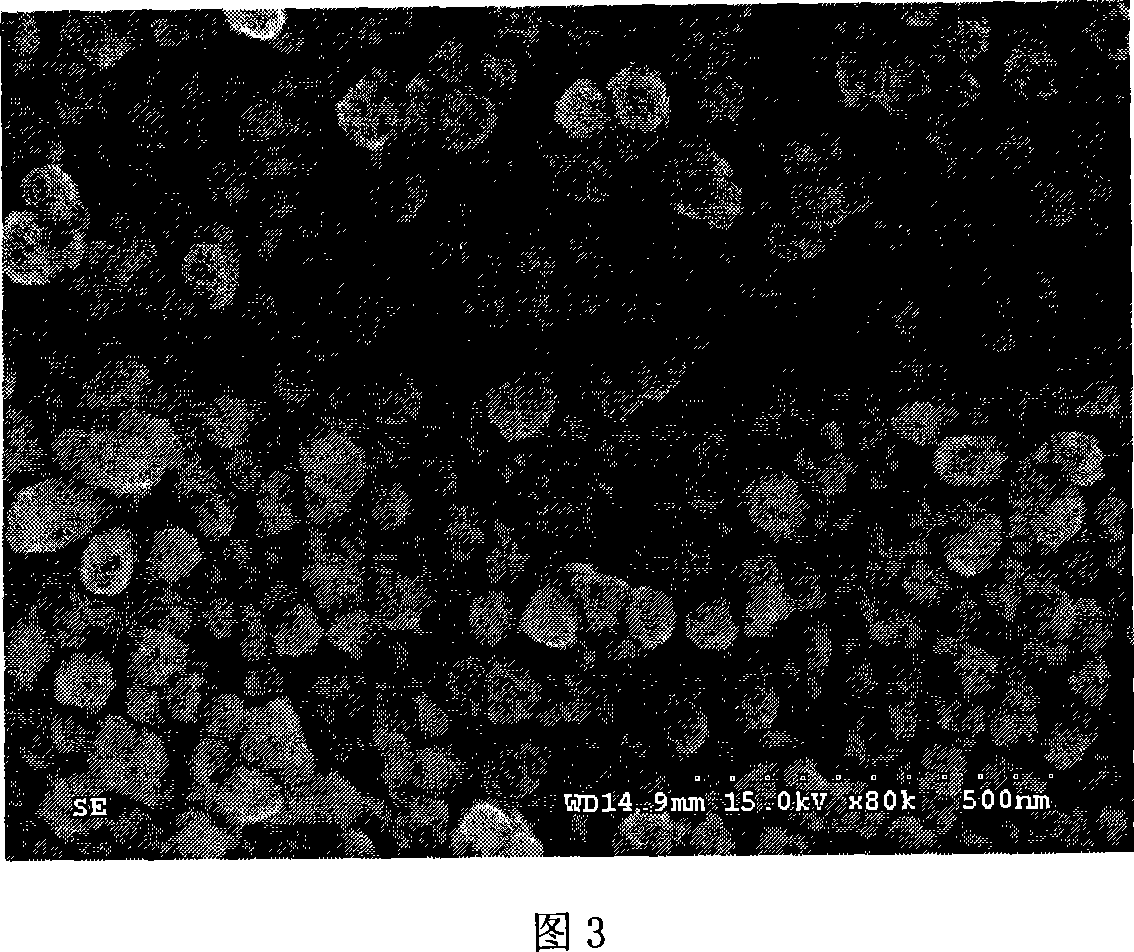

[0034] One-dimensional zinc oxide with a diameter of 700 nm and a length of 6.5 μm was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com