Method for synthesizing sludge dewatering agent of positive ions

A technology of sludge dehydrating agent and synthesis method, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., to achieve the effects of reducing production costs, no secondary pollution, and less reaction components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

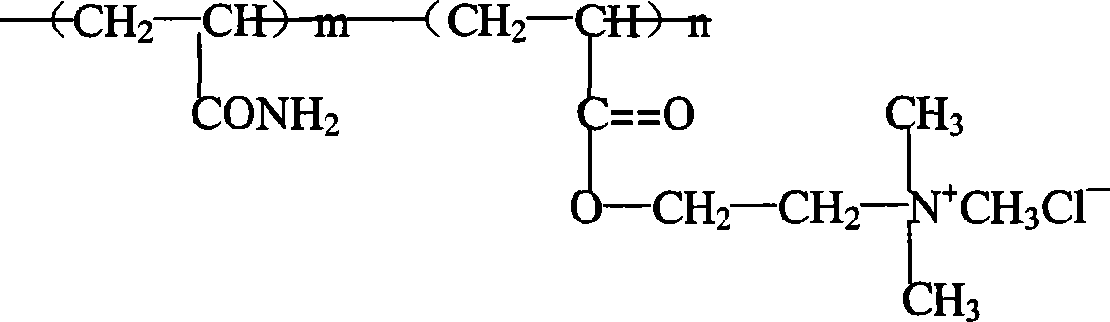

Image

Examples

Embodiment 1

[0030] The concrete steps of a kind of synthetic method of cationic sludge dewatering agent are as follows:

[0031] (1) Dosing in sequence and stirring evenly

[0032] Under normal pressure, in a device equipped with stirring equipment and constant temperature equipment and at least three feeding ports, the following operations are performed in sequence:

[0033] ①Under the conditions of a constant temperature water bath with an initiation temperature of 25°C, first add deionized water, monomer acrylamide (AM), and acryloyloxyethyltrimethylammonium chloride (DAC) aqueous solution, and stir evenly to prepare the total The mass concentration of the monomer (referring to the percentage of the monomer mass in the total mass of the system) is 35% monomer aqueous solution. The molar ratio of the two monomers acrylamide and acryloyloxyethyltrimethylammonium chloride is 4:1.

[0034] ② After step (1)-① is completed, add buffer solution to the monomer aqueous solution prepared in st...

Embodiment 2

[0044] The concrete steps of a kind of synthetic method of cationic sludge dewatering agent are as follows:

[0045] (1) Dosing in sequence and stirring evenly

[0046] Under normal pressure, in a device equipped with stirring equipment and constant temperature equipment and at least three feeding ports, the following operations are performed in sequence:

[0047] ①Under the conditions of a constant temperature water bath with an initiation temperature of 35°C, first add deionized water, monomer acrylamide (AM), and acryloyloxyethyltrimethylammonium chloride (DAC) aqueous solution, and stir evenly to prepare the total The mass concentration of the monomer (referring to the percentage of the monomer mass in the total system mass) is 20% monomer aqueous solution. The molar ratio of the two monomers acrylamide and acryloyloxyethyltrimethylammonium chloride is 2:1.

[0048] ② After step (1)-① is completed, add buffer solution to the monomer aqueous solution prepared in step (1)-...

Embodiment 3

[0058] The concrete steps of a kind of synthetic method of cationic sludge dewatering agent are as follows:

[0059] (1) Dosing in sequence and stirring evenly

[0060] Under normal pressure, in a device equipped with stirring equipment and constant temperature equipment and at least three feeding ports, the following operations are performed in sequence:

[0061] ①Under the conditions of a constant temperature water bath with an initiation temperature of 40°C, first add deionized water, monomer acrylamide (AM), and acryloyloxyethyltrimethylammonium chloride (DAC) aqueous solution, and stir evenly to prepare the total The mass concentration of the monomer (referring to the percentage of the monomer mass in the total system mass) is 10% monomer aqueous solution. The molar ratio of the two monomers acrylamide and acryloyloxyethyltrimethylammonium chloride is 7:1.

[0062] ② After step (1)-① is completed, add buffer solution to the monomer aqueous solution prepared in step (1)-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com