Mineral floating collecting agent and its prepn process

A technology of collectors and cationic collectors, applied in flotation, solid separation, etc., can solve problems such as inability to obtain qualified concentrates, and achieve the effects of good selectivity, good biodegradability, and less foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The method for preparing the collector for the above-mentioned mineral flotation provided by the present invention is as follows: first react fatty alcohol with sodium hydroxide or potassium hydroxide under anhydrous conditions to prepare sodium alkoxide or potassium alkoxide; Potassium alkoxide is used as a catalyst to polymerize acrylonitrile and aliphatic alcohol to form ether nitrile, and the ether nitrile is hydrogenated under the action of an amorphous metal catalyst, cooled and discharged, and then the intermediate is used as a raw material to react with acrylonitrile , and then under the action of an amorphous catalyst, hydrogenation changes the nitrile group into an amine group, and undergoes multiple polymerization hydrogenation, thereby obtaining the collector for the mineral flotation.

[0023] According to different purposes, the present invention controls the number of times of polymerization and hydrogenation; first polymerization and hydrogenation obtains...

Embodiment 1

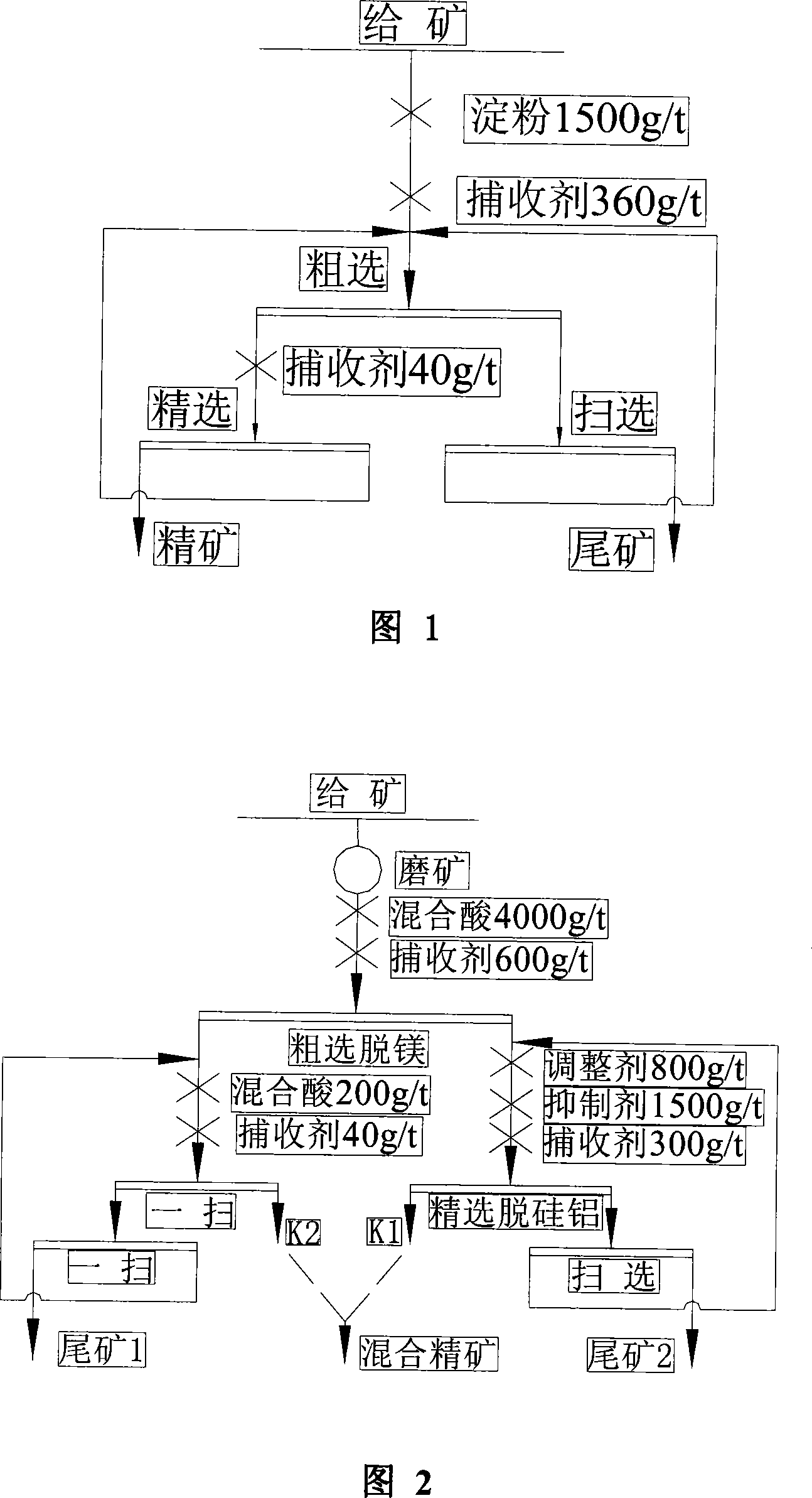

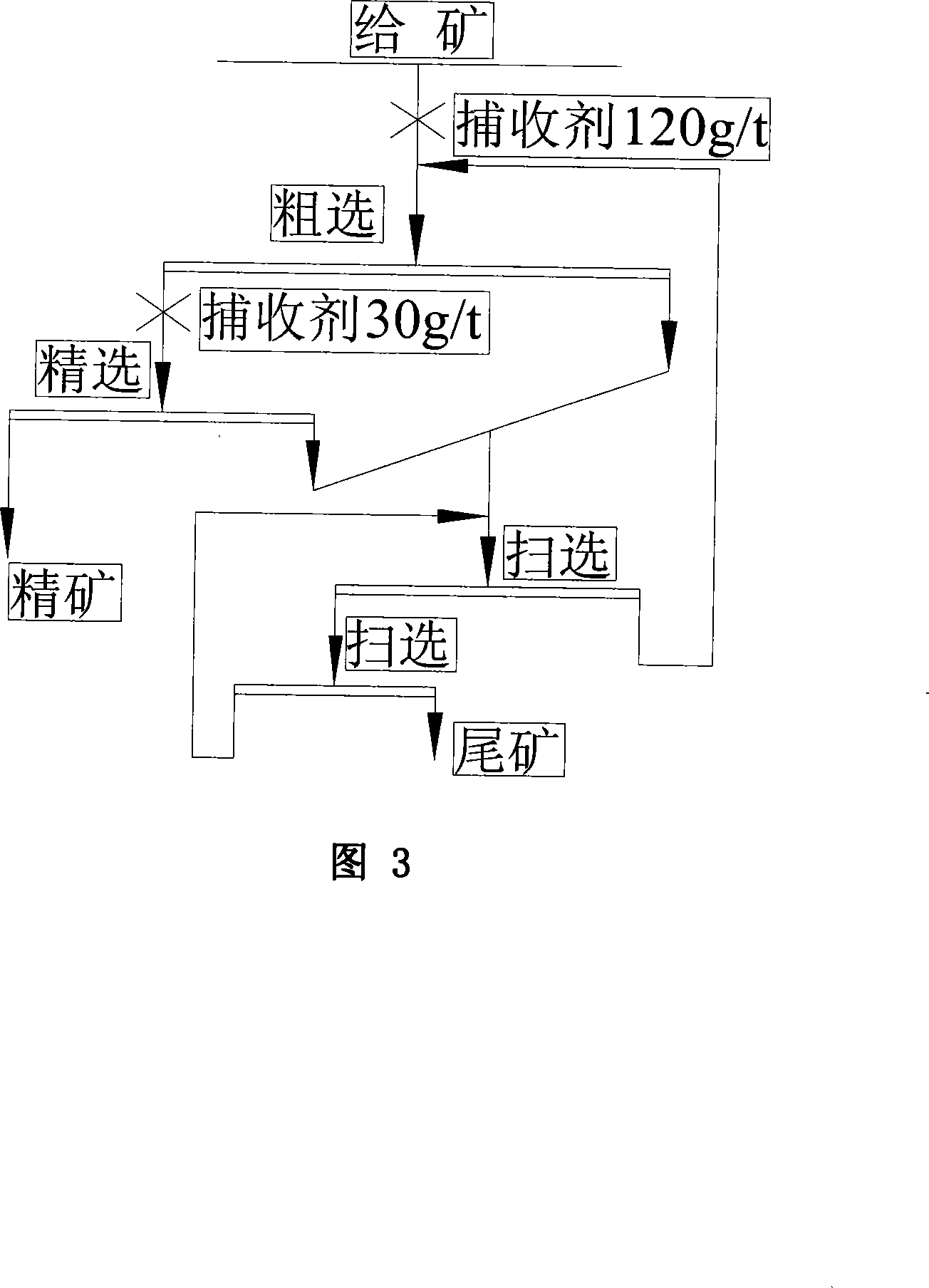

[0033] Embodiment 1: be used for the collector of hematite reverse flotation

[0034] The process of drug synthesis is: first use 10% of the amount of C 12 ~C 14 Fatty alcohol reacts with 3-5% NaOH, the reaction temperature is 80±5°C, and the reaction time is 0.5-1.0 hours, thereby preparing sodium alkoxide. Use this material as a catalyst, in the reactor, first add C 12 ~C 14 Fatty alcohol, add the same mole of acrylonitrile dropwise, control the reaction temperature at 40-50°C, and the reaction time for 2.5-3.0 hours, take samples to analyze the completion of the polymerization reaction, when the polymerization reaction rate reaches 95%, it means the reaction is complete, and the polymer is obtained by filtration. Feed the polymer into the autoclave, add an amorphous metal alloy catalyst, control the reaction conditions for hydrogenation, pressure 2.0-3.0MPa, temperature 140-180°C, hydrogenation reaction for 2 hours, sample and analyze the content of the finished product,...

Embodiment 2

[0036] Example 2: Collector for reverse flotation and desilication of phosphate rock

[0037] The synthesis steps of the medicament are: first use 10% C 10 ~C 14 Fatty alcohol reacts with 3-5% NaOH, the reaction temperature is 80±5°C, and the reaction time is 0.5-1.0 hours to prepare sodium alkoxide. Using sodium alkoxide as a catalyst, in the reactor, first add C 10 ~C 14 Fatty alcohol, add the same mole number of acrylonitrile dropwise, control the reaction temperature at 40-50°C, and the reaction time for 2.5-3.0 hours, take samples to analyze the completion of the polymerization reaction, stop the reaction when the polymerization reaction rate reaches 95%, and filter the product. The clear liquid is fed into the autoclave, an amorphous metal nickel alloy catalyst is added, and the reaction conditions are controlled for hydrogenation. The conditions are: pressure 2.0-3.0MPa, temperature 140-180°C, hydrogenation reaction for 2 hours, sampling and analysis of finished pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com