An environmental protective wet towel and preparation method

A technology for wet wipes and environmental protection, applied in the direction of melt spinning, cardboard products, etc., can solve the problems of complex production process, difficult recycling, difficult decomposition, etc., and achieve the effect of low price, no irritation to the skin, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

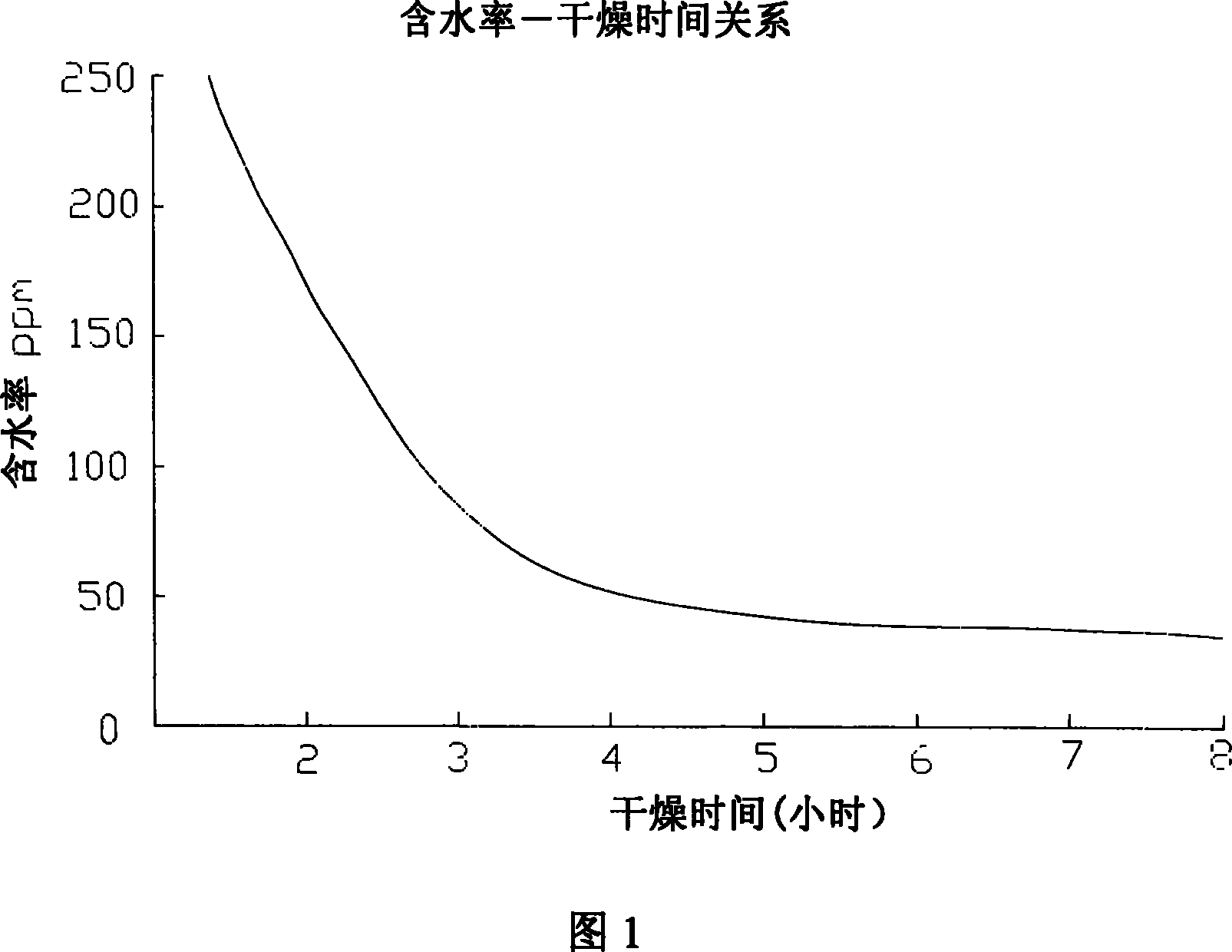

[0043] Using poly-L-lactic acid with a melt index of about 30 and no moisture as raw material, first dry the air with a dew point lower than -30°C in an environment of 80°C to a temperature higher than 0.015m 3 / min flow rate for drying for 6 hours, until the moisture content is below 50ppm, and then conveying;

[0044] A screw extruder with a length-to-diameter ratio of 24 and a compression ratio of 3 is used. The spinning screw adopts four-stage heating, and the temperature of each stage is as follows: feeding section 25°C, zone 1 200°C, zone 2 220°C, zone 3 230°C, four zones 235°C, spinning pump temperature 235°C;

[0045] After the polylactic acid resin is extruded and melted, remove impurities; the degree of pre-filtration for removing impurities should reach 20 microns, and the filter screen of the fine filter should be 400-mesh filter screen;

[0046] During spinning, the aperture of the spinneret is 0.2mm, the aspect ratio is 2, and the temperature of the spinning hea...

Embodiment 2

[0054] Using poly-L-lactic acid with a melt index of about 30 and no moisture as raw material, first dry the air with a dew point below minus 30°C in an environment of 80°C to a temperature higher than 0.015m 3 / min flow rate for drying for 6 hours, until the moisture content is below 50ppm, and then conveying;

[0055] A screw extruder with a length-to-diameter ratio of 28 and a compression ratio of 3 is used. The spinning screw adopts four-stage heating, and the temperature of each stage is as follows: feeding section 25°C, zone 1 195°C, zone 2 215°C, zone 3 225°C, 230°C in the fourth zone, 235°C spinning pump temperature;

[0056] After the polylactic acid resin is extruded and melted, remove impurities; the degree of pre-filtration for removing impurities should reach 20 microns, and the filter screen of the fine filter should be 300-mesh filter screen;

[0057] During spinning, the aperture of the spinneret is 0.35mm, the aspect ratio is 2, and the temperature of the spi...

Embodiment 3

[0066] Using poly L-lactic acid with a melt index of about 30 as the raw material, first dry the air with a dew point below minus 30°C in an environment of 85°C at a temperature of 0.03m 3 / min flow rate for drying for 6 hours, until the moisture content is below 50ppm, and then conveying;

[0067] A screw extruder with a length-to-diameter ratio of 26 and a compression ratio of 3 is used. The spinning screw adopts four-stage heating, and the temperature of each stage is as follows: feeding section 25°C, zone 1 200°C, zone 2 225°C, zone 3 235°C, four zones 235°C, spinning pump temperature 237°C;

[0068] After the polylactic acid resin is extruded and melted, remove impurities; the degree of pre-filtration for removing impurities should reach 20 microns, and the filter screen of the fine filter should be 300-mesh filter screen;

[0069] During spinning, the aperture of the spinneret is 0.25 mm, the aspect ratio is 2, and the temperature of the spinning head is 237°C, which is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| aspect ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com