Method for preparing silicon-fluorine modified acrylic ester emulsion based on macromolecule organic silicon and fluorine-containing monomer

A technology of acrylate and silicone, which is applied in the field of preparing silicon-fluorine modified acrylate emulsion, which can solve the problems of design control, no molecular chain and latex particle type, etc., and achieve the effect of convenient operation, low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

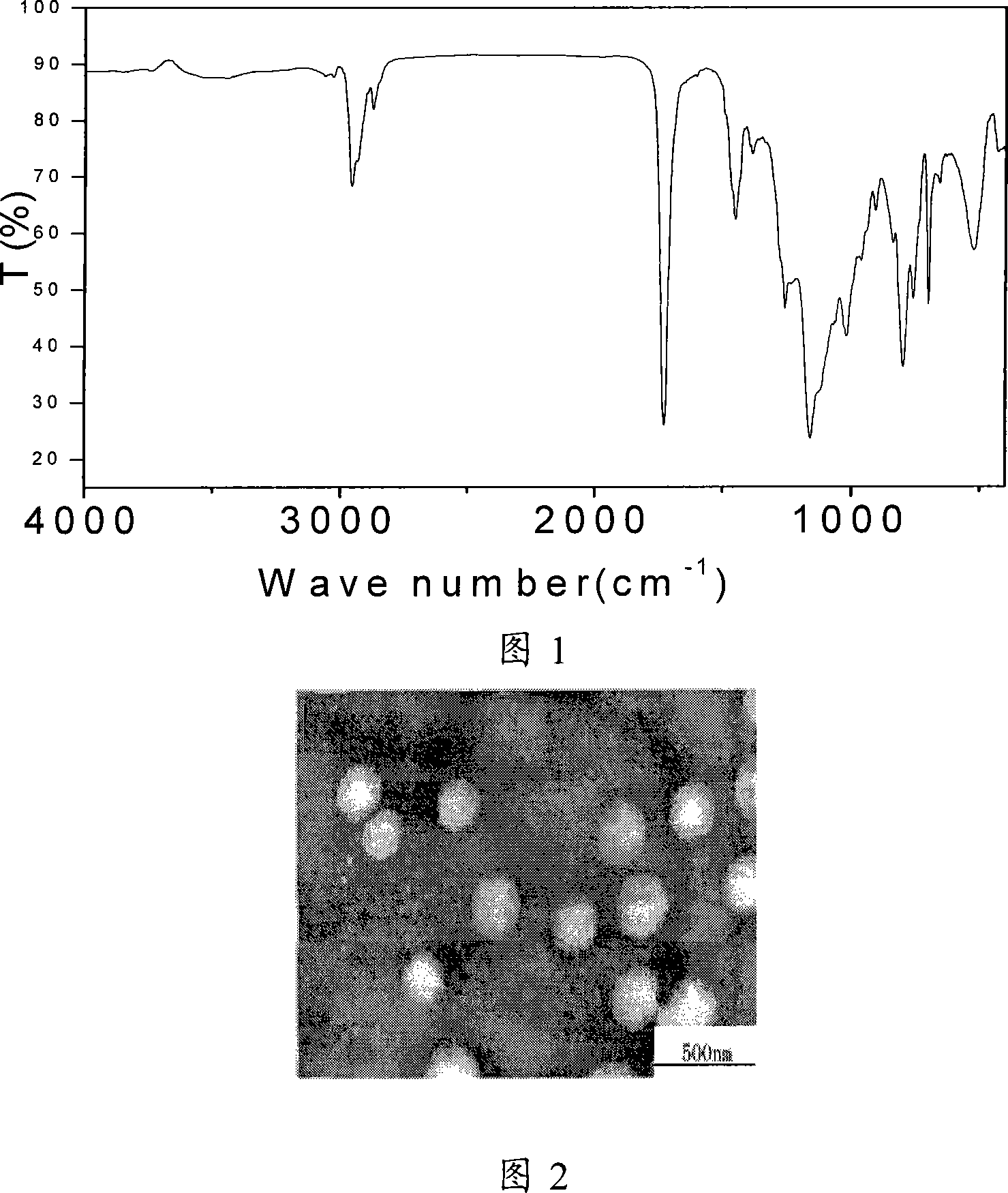

Image

Examples

Embodiment 1

[0034] ①Preparation of base liquid A: Add 35.0 parts of deionized water, 0.5 parts of sodium dodecylbenzenesulfonate, 0.5 parts of polyoxyethylene alkyl Phenyl ether. .

[0035] ②Pre-emulsion B: Add 21.0 parts of methyl methacrylate, 21.0 parts of n-butyl acrylate main monomer, 0.5 parts of sodium dodecylbenzenesulfonate, and 1.0 parts of polyoxyethylene alkylphenyl ether to 43.0 parts part deionized water, stirred and emulsified for 20 minutes;

[0036] ③When the temperature of the water bath reaches 83±2°C, add 0.20 parts of ammonium persulfate to A, and take half of B and add it dropwise to the base liquid A to obtain the core layer emulsion C. Add 7.0 parts of hydroxyl silicone oil and 5.0 parts of trifluoroethyl methacrylate to the remaining half of B, and continue to stir and emulsify to obtain pre-emulsion D; after the core layer is polymerized, add D dropwise to C to complete the verification reaction ;

[0037]④Add 1.0 parts of vinyltriethoxysilane coupling agent ...

Embodiment 2

[0040] ①Preparation of base liquid A: Add 40.0 parts of deionized water, 0.7 parts of dialkyl sodium succinate, 0.7 parts of polyoxyethylene dodecyl to the reactor with agitator, condenser and dropping device ether.

[0041] ②Pre-emulsion B: Add 18.0 parts of methyl methacrylate, 27.0 parts of octyl acrylate, 0.7 parts of sodium dialkyl succinate, and 1.4 parts of polyoxyethylene lauryl ether into 45.0 parts of deionized water, and stir Emulsify for 20 minutes;

[0042] ③When the temperature of the water bath reaches 58±2°C, add 0.05 parts of hydrogen peroxide and 0.05 parts of ferrous chloride to A, and take half of B and add it dropwise to base liquid A to obtain core layer emulsion C. Add 5.0 parts of hydroxyl silicone oil and 5.0 parts of dodecafluoroheptyl acrylate to the remaining half of B, and continue to stir and emulsify to obtain pre-emulsion D; after the core layer is polymerized, add D dropwise to C to complete the review reaction;

[0043] ④Add 1.0 parts of vin...

Embodiment 3

[0046] ①Preparation of base liquid A: Add 40.0 parts of deionized water, 0.3 parts of sodium dodecylbenzenesulfonate, 0.3 parts of polyoxyethylene sorbose to the reactor with agitator, condenser and dropping device Alcohol octanoate.

[0047] ②Pre-emulsion B: Add 18.0 parts of methyl methacrylate, 27.0 parts of octyl acrylate, 0.7 parts of sodium dodecylbenzenesulfonate, and 1.4 parts of polyoxyethylene sorbitol caprylate to 45.0 parts of deionized In water, stir and emulsify for 20 minutes;

[0048] ③When the temperature of the water bath reaches 37±2°C, add 0.05 parts of sodium persulfate and 0.15 parts of cuprous chloride to A, and take half of B and add it dropwise to the base liquid A to obtain the core layer emulsion C. Add 5.0 parts of hydroxyl silicone oil and 5.0 parts of dodecafluoroheptyl acrylate to the remaining half of B, and continue to stir and emulsify to obtain pre-emulsion D; after the core layer is polymerized, add D dropwise to C to complete the review re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface energy | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com