Method for preparing anatase type bentonite-base porous titanium dioxide nano material

A technology of porous titanium dioxide and nanomaterials, which is applied in the fields of titanium dioxide, nanostructure manufacturing, chemical instruments and methods, etc., can solve the problems of difficult control of the operation process, damage to the bentonite structure, corrosion of equipment, etc. The effect of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 100 g of bentonite was mixed with 1000 mL of 0.1084 mol / L cetyltrimethylammonium bromide aqueous solution to prepare organobentonite. Mix the organobentonite after vacuum drying for 12 hours at room temperature according to organobentonite: butyl titanate (mass ratio) = 1:5, stir and react at 50°C for 4 hours; seal the container and wrap it with tin foil to prevent the butyl titanate from being exposed to light. Esterolysis. Separation of solid and liquid, drying of the solid part at 20°C, and finally raising the temperature to 550°C at a rate of 3°C / min in an air atmosphere, and roasting for 6 hours to remove surfactants and adsorbed organic pollutants.

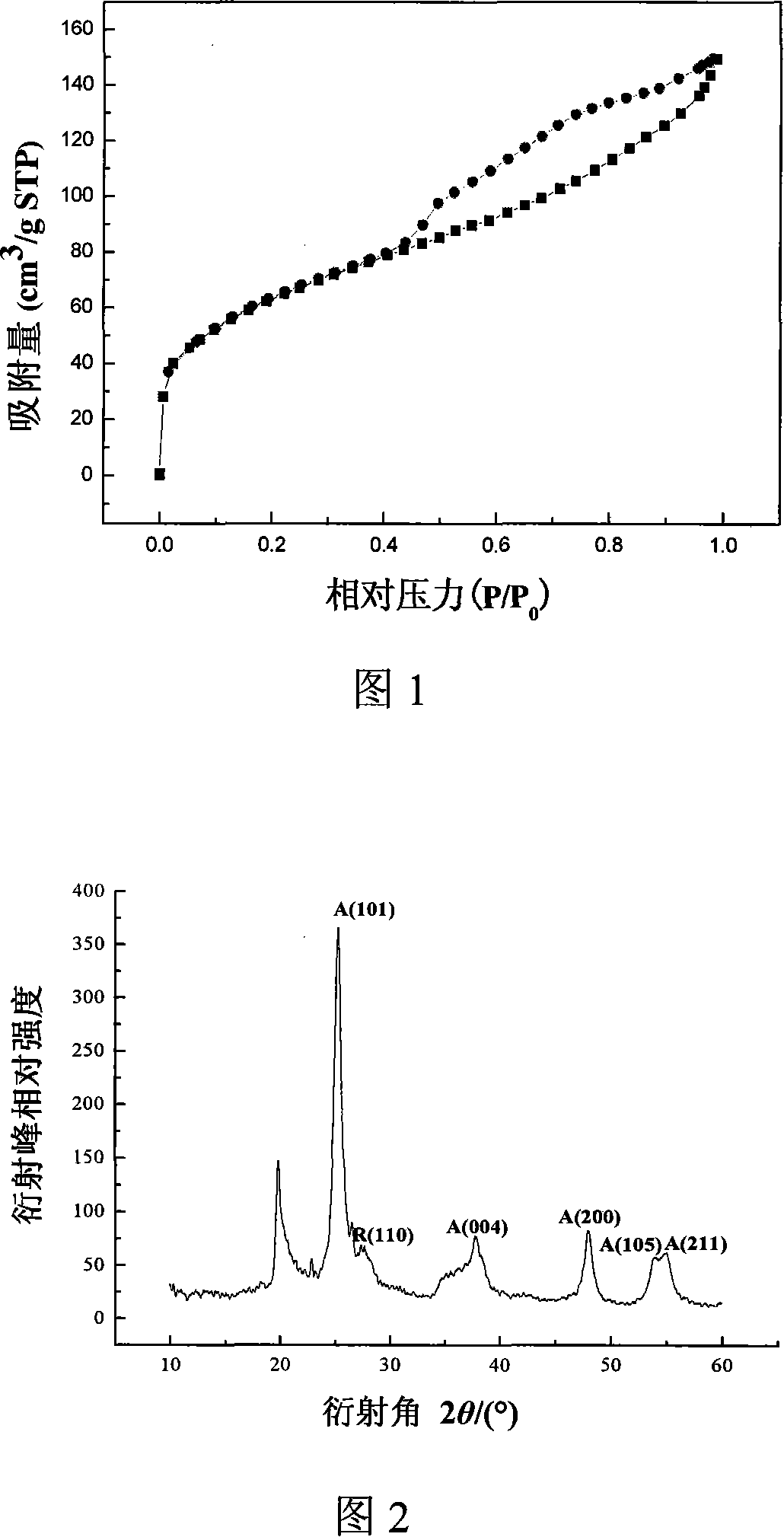

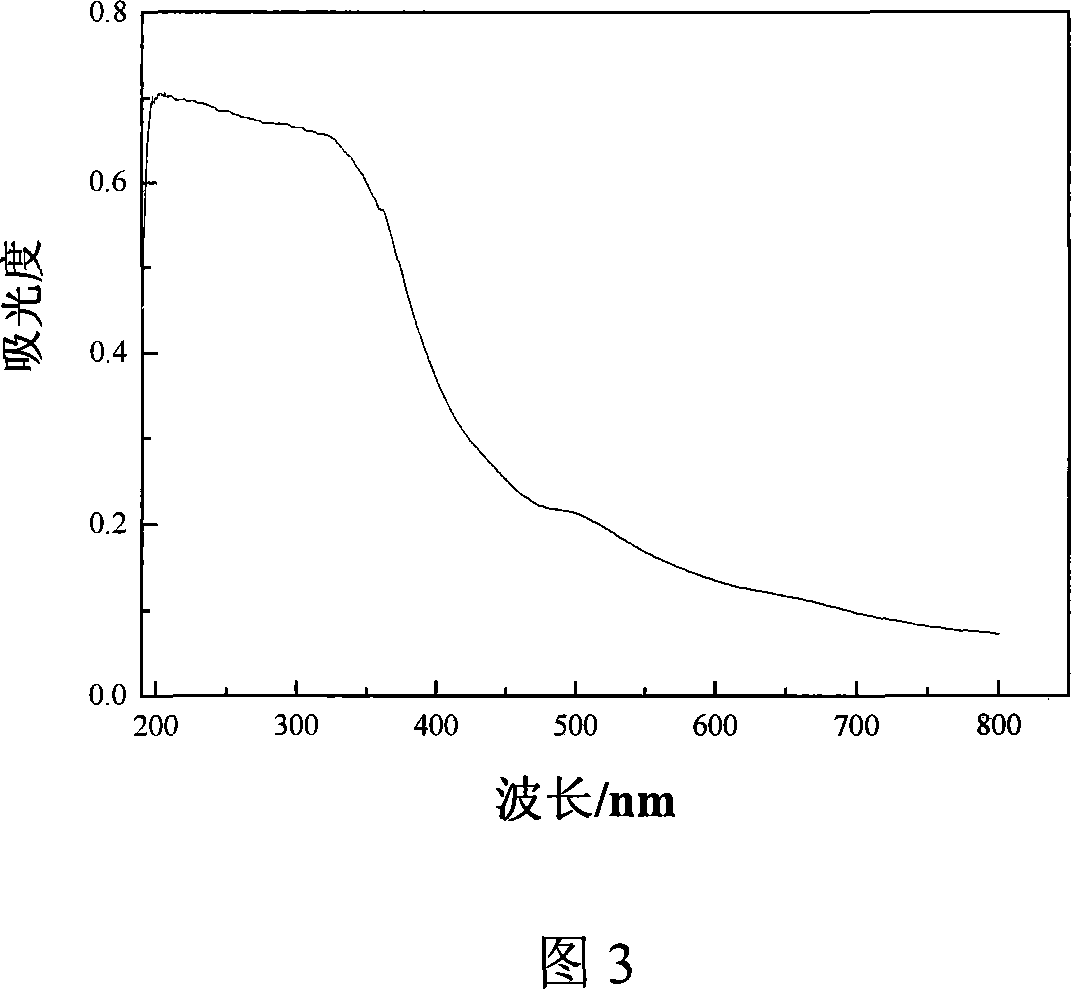

[0024] Sample test description: the product is mainly anatase type, with a particle size of 12.2nm (Figure 1); the specific surface area of the product is 241.25m 2 / g (multi-point BET method), the pore volume is 0.2391cm 3 / g, the average pore size is 3.964nm (Figure 2); the product has a strong ultraviolet effec...

Embodiment 2

[0026] 100 g of bentonite was mixed with 500 mL of 0.1084 mol / L cetyltrimethylammonium bromide aqueous solution to prepare organobentonite. The organobentonite after vacuum drying for 48 hours is first used to adsorb and treat waste water containing 2000mg / L p-nitrophenol. The adsorption capacity of organobentonite to p-nitrophenol is 122mg / g. After the organic bentonite of phenol is dried, mix according to organic bentonite: isopropyl titanate (mass ratio) = 1:22, stir and react at 20° C. for 8 hours; seal the container and wrap it with tin foil to prevent the decomposition of isopropyl titanate under light. Separation of solid and liquid, drying of the solid part at 80°C, and finally raising the temperature to 550°C at a rate of 2°C / min in an air atmosphere, and roasting for 6 hours to remove surfactants and adsorbed organic substances.

[0027] Sample test description: The product is mainly anatase, with a particle size of 14.4nm; the specific surface area of the product ...

Embodiment 3

[0029] 100 g of bentonite was mixed with 1000 mL of 0.1084 mol / L cetyltrimethylammonium bromide aqueous solution to prepare organobentonite. Mix organic bentonite and co-surfactant after vacuum drying for 2 hours according to organic bentonite: dodecylamine = 1: 0.5 (mass ratio), stir and react at 50°C for 30 minutes; (Mass ratio) = 1:5 mixed, stirred and reacted at 20° C. for 8 hours; airtight container, wrapped with tin foil to prevent decomposition of butyl titanate under light. Separation of solid and liquid, drying of the solid part at 100°C, and finally raising the temperature to 700°C at a rate of 3°C / min in an air atmosphere, and roasting for 2 hours to remove surfactants and adsorbed organic pollutants.

[0030] Sample test description: The product is mainly anatase, with a particle size of 9.7nm; the specific surface area of the product is 169.94m 2 / g (multi-point BET method), the pore volume is 0.2956cm 3 / g, the average pore size is 7.082nm; the product has a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com