Catalyzer for liquid-phase catalytic oxidation producing of chlorobenzaldehyde by using p-chlorotoluene

A technology of p-chlorobenzaldehyde and liquid phase catalysis, which is applied in the direction of hydrocarbon oxidation to prepare oxygenates, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., which can solve the problem of long reaction time and conversion rate low, the catalyst cannot be reused, etc., to achieve the effect of low reaction temperature, high reaction yield, and simple catalyst separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

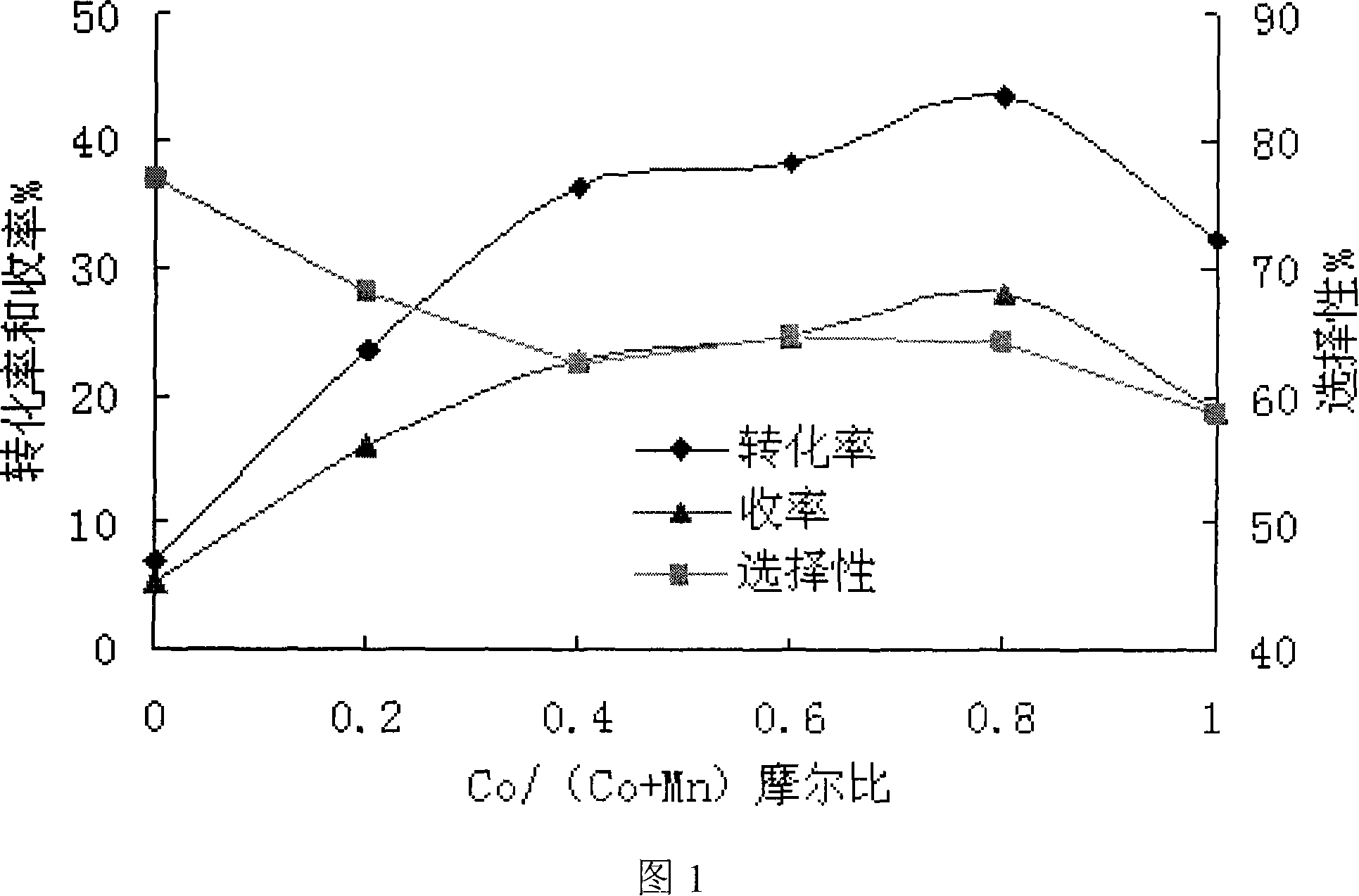

[0029] Embodiment 1: the evaluation of preparation and activity of catalyst A

[0030] 2.391g (0.0096mol) Co(OAc) 2 4H 2 O, 0.588g (0.0024mol) Mn(OAc) 2 4H 2 O and 0.714g (0.0060mol) KBr were dissolved in 50ml deionized water, heated and stirred to dissolve completely; 10.0g γ-Al 2 o 3 The carrier was poured into the above solution, evaporated to dryness at 65°C; then dried at 120°C for 3 hours, and calcined in a muffle furnace at 500°C for 3 hours. Get a catalyst.

[0031] Put 2.0g of catalyst in a 50ml three-necked flask, measure 10ml of p-chlorotoluene and 30ml of acetic acid into the three-necked flask with a pipette, and put them into a magnet; start stirring, condense and reflux (the upper end of the condenser tube is sealed with concentrated sulfuric acid liquid) ), heated to 110°C; kept at a constant temperature, fed oxygen (30ml / min), reacted for 6h, and cooled to room temperature after the reaction. Catalyst, p-chlorobenzoic acid and filtrate are separated by ...

Embodiment 2

[0032] Embodiment 2: catalyst is the same as A

[0033] Activity evaluation was the same as in Example 1 except that the reaction temperature was 100°C. The conversion rate of p-chlorotoluene is 36.6%, the selectivity of p-chlorobenzyl alcohol is 4.4%, the selectivity of p-chlorobenzaldehyde is 61.8%, the selectivity of p-chlorobenzoic acid is 33.8%, and the yield of p-chlorobenzaldehyde is 22.7%.

Embodiment 3

[0034] Embodiment 3: catalyst is the same as A

[0035] The activity evaluation was the same as in Example 1 except that the solvent acetic acid was 20 ml. The conversion rate of p-chlorotoluene is 43.7%, the selectivity of p-chlorobenzyl alcohol is 7.4%, the selectivity of p-chlorobenzaldehyde is 64.3%, the selectivity of p-chlorobenzoic acid is 28.3%, and the yield of p-chlorobenzaldehyde is 28.1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com