High heat-conductive diamond-copper composite encapsulating material and method for making same

A technology for encapsulating materials and diamonds, which is applied in chemical instruments and methods, and other chemical processes, etc. It can solve the problems that the detailed preparation process is not disclosed, affect the structure and performance of materials, and achieve simple and reliable preparation methods, improve wettability, and increase strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

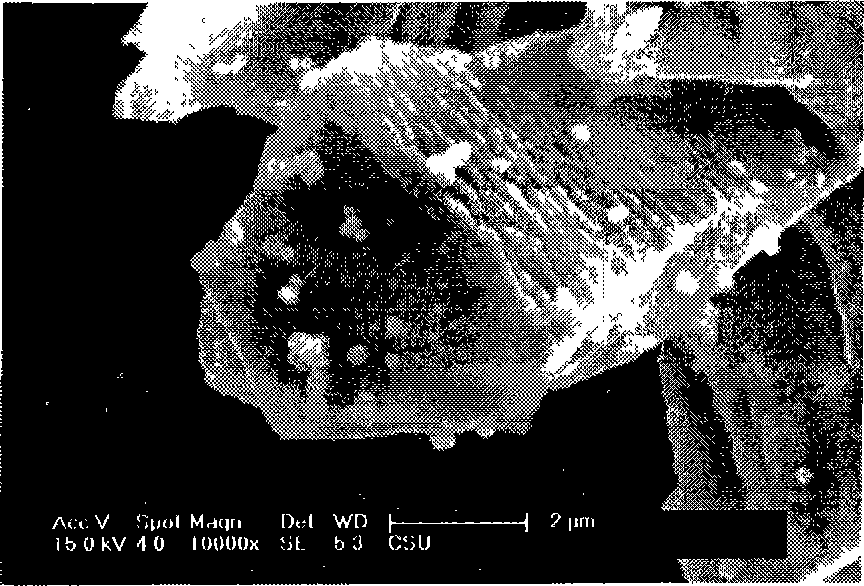

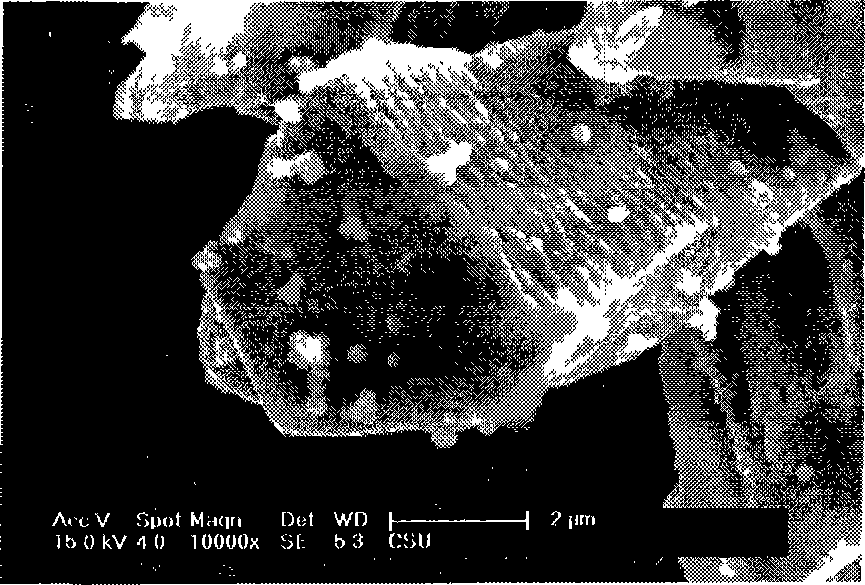

[0032] ①Firstly, the raw material is pretreated, copper powder (-200 mesh) reduction treatment: the copper powder raw material is reduced with hydrogen in a reduction furnace, the reduction temperature is 500 ° C, and the time is 2 hours; the surface of the diamond particles (average particle size 5 μm) is electroless Ni-plated -W, the coating thickness is 0.8 μm, the electroless plating process conditions are shown in Table 1, and the SEM photo of diamond particles after Ni-W electroless plating is shown in Figure 1;

[0033] ② Mixing: Weigh 95g of the pretreated copper powder, add it together with 5g of electroless Ni-W-plated diamond particles into a polyurethane ball mill tank, mix in a three-dimensional mixer, and mix for 3 hours;

[0034] ③Hot-press sintering: put the mixture into a hot-pressed graphite mold, put it into a vacuum hot-pressed sintering furnace, sintering temperature is 750°C, pressing pressure is 20MPa, and sintering time is 1 hour;

[0035] ④Material pro...

Embodiment 2

[0037] ①Firstly, pre-treat the raw materials, copper powder (-200 mesh) reduction treatment: reduce the copper powder raw material with hydrogen in a reduction furnace, the reduction temperature is 300 ° C, and the time is 3 hours;

[0038] ② Mixing: Weigh 94g of pretreated copper powder, 5g of diamond powder (10μm), and 1g of tungsten powder (0.1μm) into a polyurethane ball mill tank, mix in a three-dimensional mixer, and mix for 5 hours;

[0039] ③Hot-press sintering: put the mixture into a hot-pressed graphite mold, put it into a vacuum hot-pressed sintering furnace, sintering temperature is 500°C, pressing pressure is 5MPa, and sintering time is 3 hours;

[0040] ④Material processing: Wire cutting was used to process the hot-pressed sintered product into the required size for analysis and testing. The test results are shown in Table 2, and the metallographic photos (634 times) are shown in Figure 3.

Embodiment 3

[0042] ① First, pre-treat the raw materials, copper powder (-200 mesh) reduction treatment: reduce the copper powder raw material with hydrogen in a reduction furnace, the reduction temperature is 700 ° C, and the time is 0.5 hours;

[0043] ② Mixing: Weigh 60g of pretreated copper powder, 30g of diamond powder (1.0μm), 5g of iron powder (2.0μm), and 5g of molybdenum powder (1.0μm) and add them to the polyurethane ball mill tank together. Mixing, mixing time 5 hours;

[0044] ③Hot-press sintering: put the mixture into a hot-pressed graphite mold, put it into a vacuum hot-pressed sintering furnace, sintering temperature is 950°C, pressing pressure is 30MPa, and sintering time is 0.5 hours;

[0045] ④Material processing: The hot-pressed sintered product was processed into the required size by wire cutting for analysis and testing. The testing results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com