Method for separating and modifying biomass cracking oil to modified biological oil

A technology of biomass pyrolysis oil and bio-oil, which is applied in the field of separation and modification of pyrolysis oil, can solve the problem of not effectively improving the oxygen content, water content, calorific value and combustion performance of bio-oil, and the corrosion and catalytic effects of emulsified oil on engines. Problems such as the complexity of hydrogenation equipment, to achieve the effect of increasing heat utilization, increasing the rate of esterification reaction, and improving storage stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

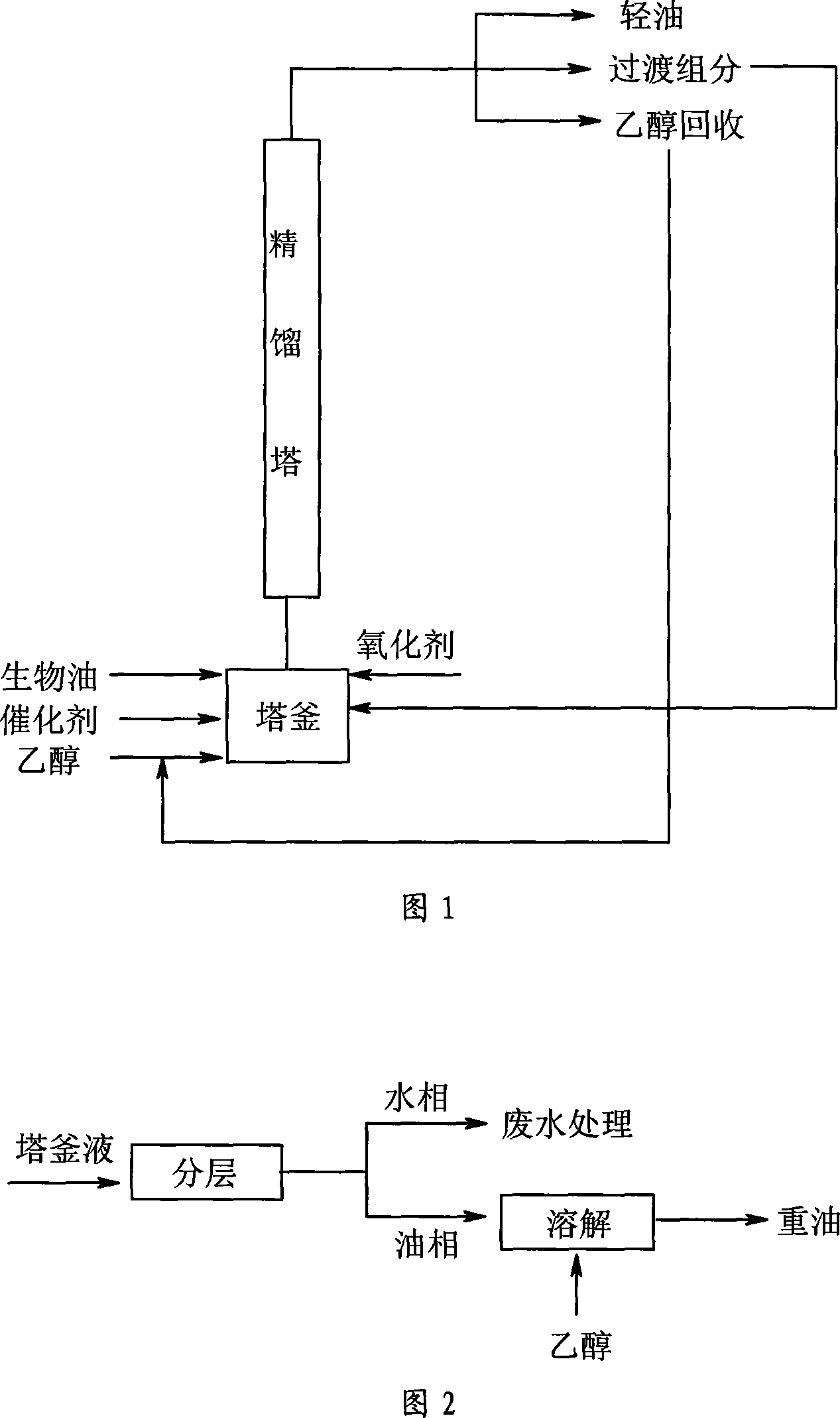

Embodiment 1

[0018] Add 50g of biomass pyrolysis oil, 30g of absolute ethanol, and 1g of concentrated sulfuric acid into the still of a rectification tower with an inner diameter of Ф24mm and a filling height of 600mm, and heat to reflux. At this time, the temperature of the tower is about 80-85°C , the temperature at the top of the tower is about 70-75°C. Using a dropping funnel, 20g of hydrogen peroxide solution with a mass fraction of 30% is added dropwise to the reactor at a rate of 10ml / min. When it reached 47°C, it was fully refluxed for 2 hours. When the temperature at the top of the rectification tower is less than 55°C, use the reflux ratio of 1:1 to extract 12.4 grams of light oil, 10.2 grams of transition components at 55-78°C, and recover ethanol at 78-79°C 22.7 grams. The liquid in the tower kettle was cooled, and the phases were separated to obtain 13.4 grams of an oil phase, which was dissolved in 7 grams of ethanol to obtain a heavy oil.

Embodiment 2

[0020] Add 50g of biomass pyrolysis oil, 100g of absolute ethanol, and 1g of concentrated sulfuric acid into the still of a rectification tower with an inner diameter of Ф24mm and a filling height of 1000mm, heat to reflux, and use a dropping funnel to dissolve 30% of the mass fraction 20g of hydrogen peroxide solution was added dropwise to the reaction kettle at a rate of 10ml / min, and the total reflux was performed for 15 minutes after the dropwise addition, and the total reflux was performed for 2 hours when the tower top temperature reached 47°C. When the temperature at the top of the rectification tower is less than 55°C, use the reflux ratio of 1:1 to extract 10.3 grams of light oil, 12.3 grams of transition components at 55-78°C, and recover ethanol at 78-79°C 88.2 grams. The liquid in the tower kettle was cooled, and the phases were separated to obtain 13.7 grams of oil phase, which was dissolved in 7 grams of ethanol to obtain heavy oil.

Embodiment 3

[0022] Add 50g of biomass pyrolysis oil, 60g of absolute ethanol, and 1g of concentrated sulfuric acid into the still of a rectification tower with an inner diameter of Ф24mm and a filling height of 800mm, heat to reflux, and use a dropping funnel to dissolve 30% of the mass fraction of 20g of hydrogen peroxide solution was added dropwise to the reactor at a rate of 10ml / min, and refluxed for 15min after the dropwise addition was completed. When the temperature at the top of the rectification tower is less than 55°C, use the reflux ratio of 1:1 to extract 11.3 grams of light oil, 11.4 grams of transition components at 55-78°C, and recover ethanol at 78-79°C 48.5 grams. The liquid in the tower kettle was cooled, and the phases were separated to obtain 13.6 grams of oil phase, which was dissolved in 7 grams of ethanol to obtain heavy oil.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com