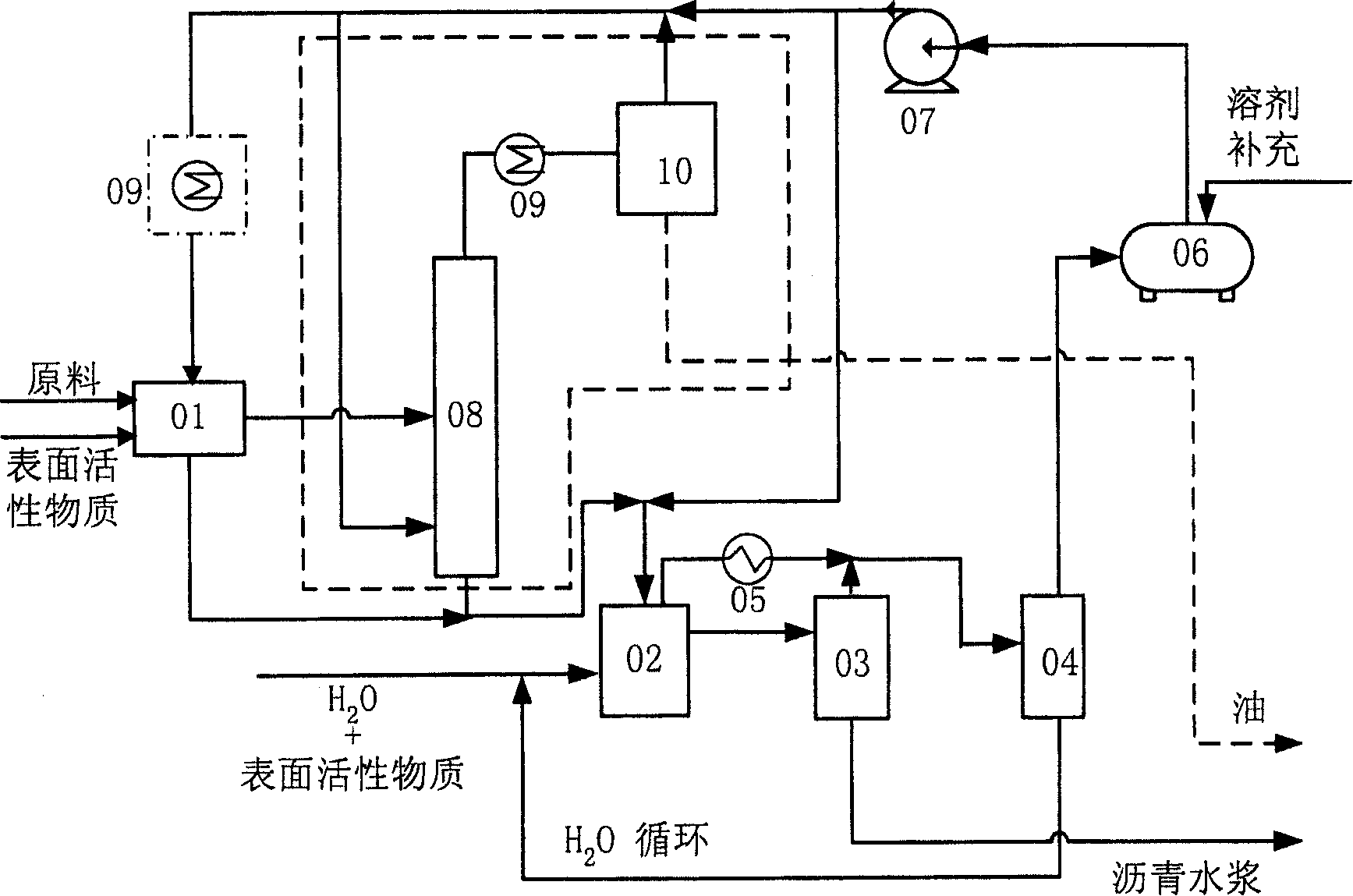

Method for preparing asphalt water slurry by granulation of petroleum series and coal series asphalt residue

A technology for asphalt residue and oil sand asphalt, which is applied in the processing of tar asphalt/petroleum asphalt/natural asphalt, petroleum industry, tar processing, etc. Raw materials and other issues, to achieve the effect of convenient recovery, simplified recovery methods, and efficient recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The tailings of coal high-pressure hydrogenation liquefaction with a softening point of 150°C are used as raw materials, and benzene is used as a solvent to directly mix and granulate the raw materials at 300°C and 5.0 MPa. The flow rate of the liquefied residue is 1.0kg / h, and the quality of the solvent and raw materials is adjusted. The mixing ratio is 1:1, and the obtained coal liquefaction tailings (bituminous phase) are mixed with the enhanced dispersion solvent (benzene), and then enter the prilling tower. The ratio of the enhanced dispersion solvent to the liquefaction residue is 0.1:1. First pass into water, the water contains a dispersed emulsifier, and the emulsifier is composed of alkylphenol polyoxyethylene ether (R(C 6 h 5 )O(CH 2 CH 2 O) n H, R=C 9 h 19 , n=10): sodium lignosulfonate: NaHCO 3 =4:4:2 (mass ratio), its content in water is 0.3m%, the addition of water is 0.3kg / h, and the water temperature is 25°C. The temperature of the prilling tower ...

Embodiment 2

[0051] The tailings of coal high-pressure hydrogenation liquefaction with a softening point of 120°C are used as raw materials, the flow rate of the liquefied residue is 10kg / h, and toluene is used as a solvent, and the flow rate is 20kg / h. At 320°C, 6.0MPa is mixed with the raw material and enters the extraction and separation tower. The mass mixing ratio of the main solvent and the raw material is 2:1, 48.2m% of the oil is extracted and separated in the separation tower, and the raffinate residue is then mixed with the enhanced dispersion solvent (toluene) and then enters the water of the prilling tower for dispersing and granulating. The ratio of dispersion solvent and raffinate residue is 0.2: 1, and dispersion emulsifier is added in water, and emulsifier is composed of polyoxyethylene (20) sorbitan monolaurate (Tween-20, C 58 h 114 o 26): sodium petroleum sulfonate (molecular weight is 500): NaOH=5: 4: 1, its add-on in water is 0.5m%, the add-on of water is 1.7kg / h, wate...

Embodiment 3

[0054] The suspension bed hydrogenation tail oil of Liaohe heavy oil with residue reduction is used as raw material, n-hexane is used as solvent, and its critical temperature is 222.0°C. The oil is first separated through the extraction tower. The solvent ratio is 0.5:1, the temperature of the extraction tower is 190° C., and the pressure is 4.0 MPa, and 75% of the oil is extracted. The raffinate residue is then mixed with an intensified dispersion solvent (n-hexane), and enters the prilling tower. The ratio of the intensified dispersion solvent to the raffinate residue is 0.15:1. Add a dispersing emulsifier in the water, and the emulsifier is composed of polyoxyethylene (20) sorbitan monostearate (Tween-60, C 64 h 126 o 26 ): sodium petroleum sulfonate (molecular weight is 500): NaOH=5: 4: 1, and its addition is 0.75m% of raw material (above-mentioned raffinate residue). The amount of water added is 7.0kg / h, and the water temperature is 30°C. The temperature of the prilli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com