Production method for tin-copper-cobalt ternary alloy cathode material of lithium ion battery

A technology for lithium ion batteries and negative electrode materials, which is applied in battery electrodes, electrical components, circuits, etc., can solve the problems of affecting the charge-discharge cycle stability of electrodes, unsatisfactory cycle stability performance, and damage to the structure of alloy negative electrodes, and achieve large-scale applications. value, improving cycle stability, and the effect of not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Accurately weigh 1g of SnO, 0.1476g of CuO, 0.1391g of CoO, and 0.1338g of activated carbon as initial raw materials (the molar ratio of raw materials is 4:1:1:10, equivalent to the atomic ratio of Sn / Cu / Co being 4:1:1), After grinding the mixture evenly, place it in a flowing nitrogen atmosphere and raise the temperature to 1000°C at a rate of 10°C / min, keep it warm for 3 hours, then turn off the power, and cool naturally to room temperature to obtain a tin-copper-cobalt alloy.

Embodiment 2

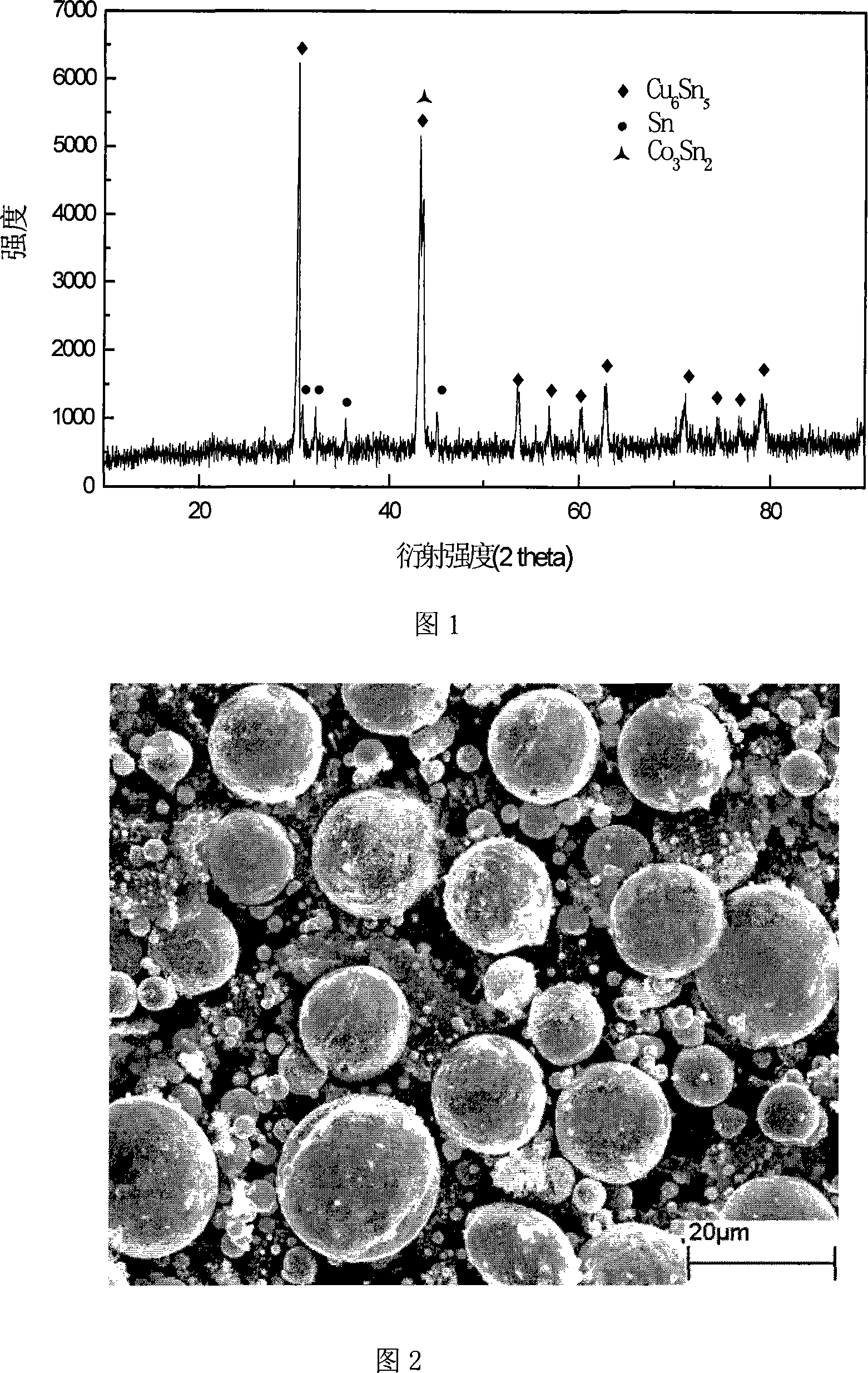

[0023] Accurately weigh 1g SnO 2 , 0.5279g CuO, 0.1065gCo 3 o 4 , and 0.2604g activated carbon as the initial raw material (raw material molar ratio 15: 15: 1: 49, equivalent to the atomic ratio of Sn / Cu / Co is 5: 5: 1), after the mixture is ground evenly, it is placed in flowing argon Raise the temperature to 900°C at a rate of 5°C / min in an air atmosphere, keep it warm for 2 hours, then turn off the power, and cool naturally to room temperature to obtain a tin-copper-cobalt alloy. The XRD phase analysis result of gained sample shows that the synthetic product is Cu 6 sn 5 , Sn and Co 3 sn 2 Alloy composite without any oxide impurity phase.

[0024] Add 10wt% conductive agent acetylene black and 10wt% binder PVDF to the synthesized material to make a slurry, apply it evenly on the copper foil, and after drying, stick it into a circular pole piece. The lithium sheet is used as the negative electrode, and the resulting pole piece is used as the positive electrode. The ele...

Embodiment 3

[0026] Accurately weigh 1g SnO 2 , 0.2374g Cu 2 O, 0.2486gCoO, and 0.2192g carbon black are used as initial raw materials (the molar ratio of raw materials is 4:1:2:11, the atomic ratio equivalent to Sn / Cu / Co is 2:1:1), after the mixture is ground evenly, set Raise the temperature to 800°C at a rate of 2°C / min in a flowing argon atmosphere, keep it warm for 2 hours, then turn off the power, and cool naturally to room temperature to obtain a tin-copper-cobalt alloy. The XRD phase analysis result of gained sample shows that the synthetic product is Cu6 sn 5 and Co 3 sn 2 Alloy composite without any oxide impurity phase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com