Industrial preparation method of rhamnolipid biological fermentation liquor

A rhamnolipid and bio-fermentation technology, which is applied in biochemical equipment and methods, microorganism-based methods, fermentation, etc., can solve the problems of no preparation method, high cost, and low efficiency in the industrialized large-scale production stage, and achieve a short cycle , improved recovery and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

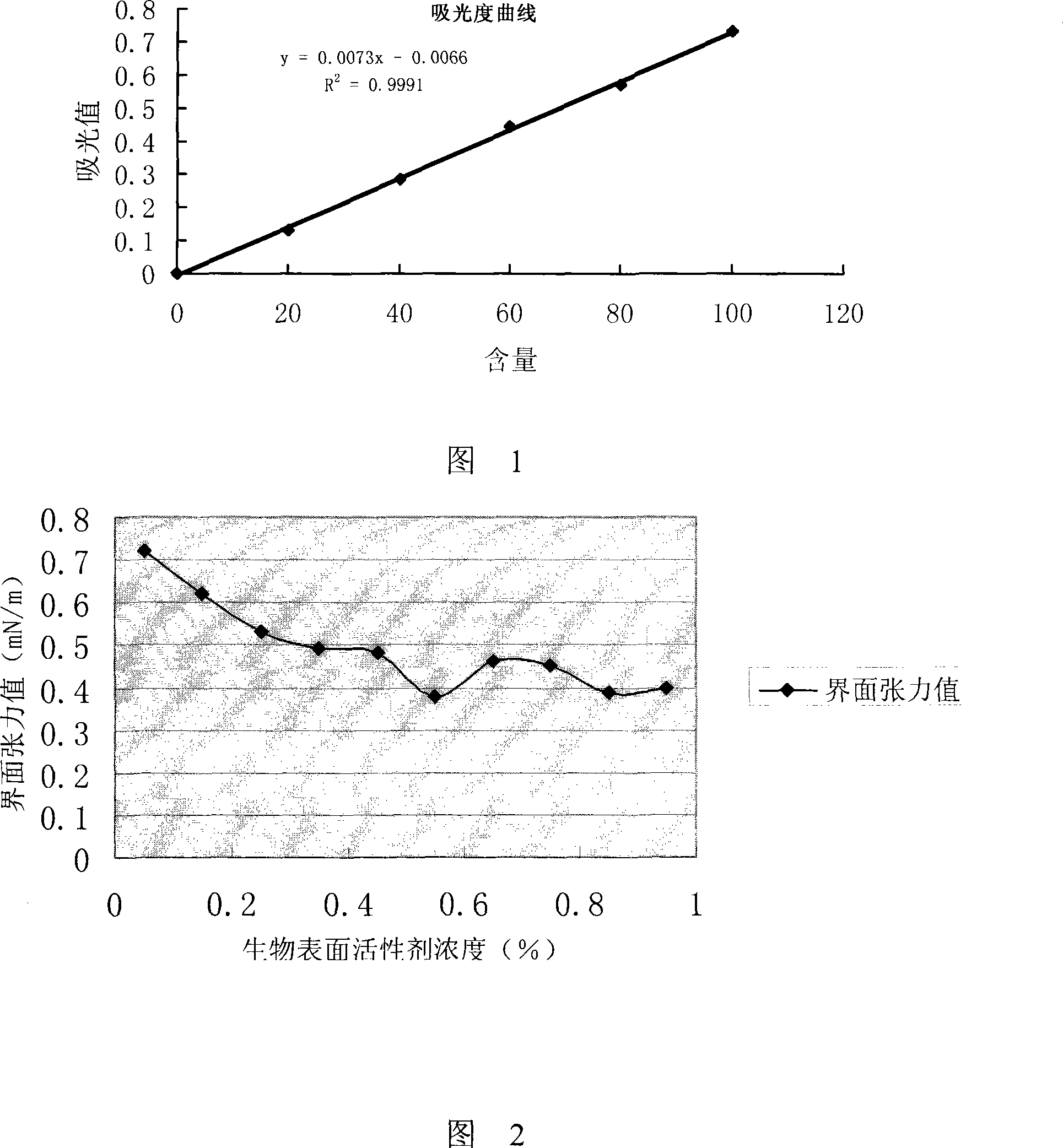

Image

Examples

Embodiment 1

[0010] Embodiment 1, chemical mutagenesis screening high-yield strains:

[0011] The medium used in the following experiments is as follows: Enrichment medium: 3g of beef extract, 10g of peptone, 5g of NaCl, 1000mL of double distilled water and 20g of agar, pH7.0~7.2. Blood agar plate medium: this medium was purchased from Beijing Yide Yihua Technology Co., Ltd.; blue agar plate medium: ammonium sulfate 0.1%, sodium nitrate 0.2%, magnesium sulfate 0.03%, potassium dihydrogen phosphate 1%, hydrogen phosphate Disodium 0.4%, yeast powder 0.05% and the rest of water, pH 7.0-7.2, coarse filter paper soaked in crude oil.

[0012] Screening steps:

[0013] 1. Enrichment culture of bacterial strains:

[0014] Weigh 1g of soil contaminated by crude oil for a long time and dissolve it in 100ml of sterile water, draw 1mL into the enrichment medium, and place it in a constant temperature shaking incubator at 37°C for 24 hours.

[0015] 2. Separation and purification:

[0016] Take 0.2...

Embodiment 2

[0044] Embodiment 2, industrialized method produces rhamnolipid biological fermentation liquid:

[0045] Shake flask and fermenter medium formulations are: corn oil 2%, urea 1%, molasses 15%, KCl 0.1%, KH 2 PO 4 0.05%, K 2 HPO 4 0.3%, yeast extract 0.005%, composite trace elements 0.008%, the rest is water, pH is 6.5, the composite trace elements are Zn 1.5g / L, Cu 1.0g / L, Mn 1.0g / L, Se 1.5g / L, Co 1.0g / L and solvent water.

[0046] Shake flask and fermenter culture:

[0047] Utilize the slant bacterial classification of embodiment 1 gained, cultivate 30h, transfer into 5L shaking flask (fill 2L substratum), inoculum size 5% (bacteria solution concentration is in OD 600 =0.8~1.0), the temperature is 32±2°C, 120rpm cultivated for 14h, transferred to a 500-liter primary fermenter, the filling coefficient is 70%, the inoculum size is 5%, the temperature is 32±2°C, and the ventilation ratio is 1:1, pH 6.5-7.5, stirring speed 100rpm, culture for 12 hours, transfer to a 3.5-t...

Embodiment 3

[0048] Embodiment 3, industrialized method produces rhamnolipid biological fermentation liquid:

[0049] Shake flask and fermenter medium formulations are: corn oil 3%, urea 1.5%, molasses 17%, KCl 1.0%, KH 2 PO 4 0.2%, K 2 HPO 4 1.5%, yeast extract 0.02%, composite trace elements 0.01%, the rest is water, pH is 6.5, the composite trace elements are Zn 1.5g / L, Cu 1.0g / L, Mn 1.0g / L, Se 1.5g / L, Co 1.0g / L and solvent water.

[0050] Shake flask and fermenter culture:

[0051] Utilize the slant bacterial classification of embodiment 1 gained, cultivate 30h, transfer into 5L shaking flask (filling into 2L culture medium), inoculum size 5%, 32 ± 2 ℃, 120rpm cultivate 16h, transfer into 500 liters of primary fermentation tank, the filling coefficient is 67%, the inoculum size is 5%, the ventilation ratio is 1:1 at 32±2°C, the pH is 6.5-7.5, the stirring speed is 120rpm, and the stirring speed is 120rpm. The material coefficient is 67%, the inoculum size is 5%, 32±2°C, the ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com