Method for preparing photocatalyst doping with mesopore nanometer titanium oxide

A nano-titanium oxide and photocatalyst technology, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as differences in photocatalyst performance, and achieve increased practicability, effective doping, high The effect of catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

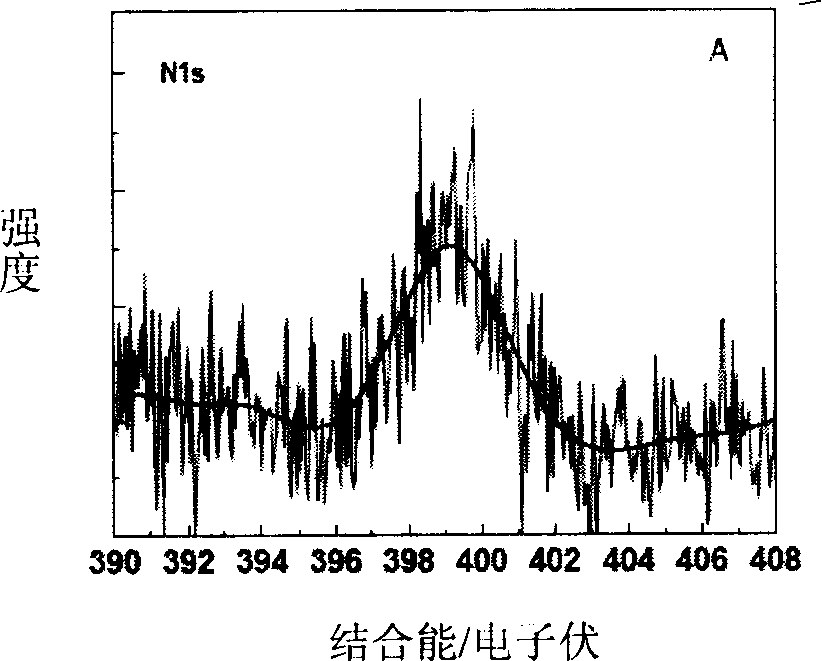

Embodiment 1

[0029] Dissolve 10ml of tetrabutyl titanate in 35ml of tetrabutanol, stir for 2 hours to form a uniformly dispersed solution; then add dropwise to 100ml of deionized water acidified with nitric acid (pH=3) for hydrolysis, and form a uniformly dispersed solution after stirring for 5 hours Emulsion, the resulting emulsion was transferred to a 250ml reactor for hydrothermal treatment at 100°C for 8h. Then 1g of hexamethylenetetramine was dissolved into the emulsion after hydrothermal treatment, and the solution was added dropwise to 50ml of aqueous solution in which 5g of P123 surfactant was dissolved. The whole dropping process was stirred and dropped in a water bath at 50°C, stirred for 2h (uniformly), then moved back into the reactor, and then hydrothermally treated at 130°C for 36h. Finally, the obtained emulsion was dried at 90°C and sintered at 500°C for 3 h (the heating rate was 3°C min -1 , with a cooling rate of 4°C min -1 ), to obtain nitrogen-doped mesoporous nanocry...

Embodiment 2

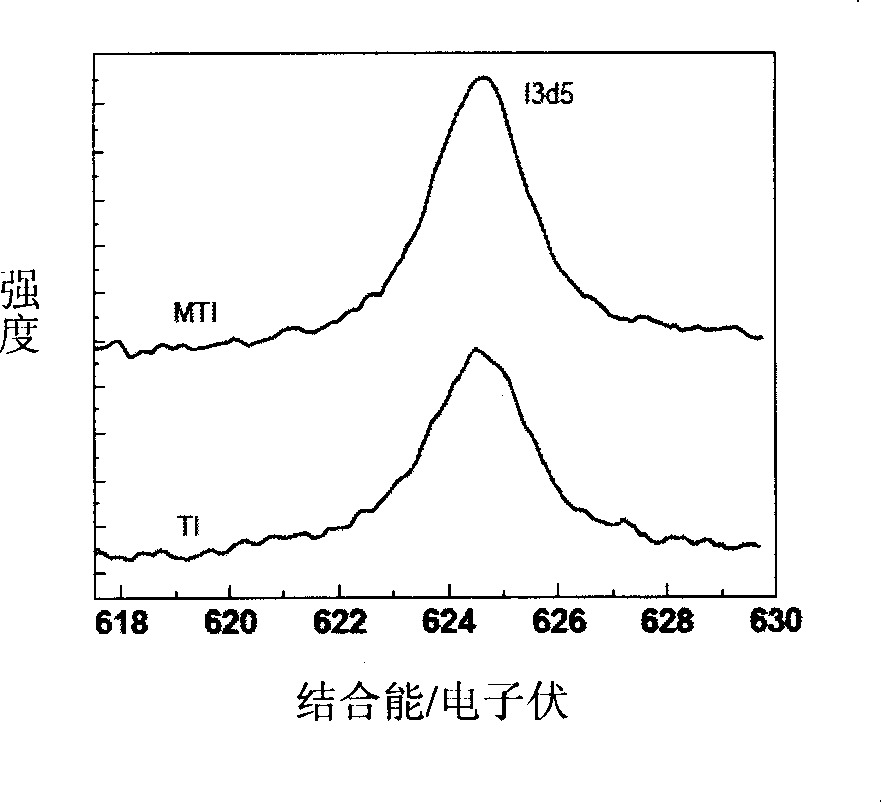

[0034]Dissolve 16ml of isopropyl titanate in 40ml of isopropanol, stir for 3 hours to form a uniformly dispersed solution; then add dropwise to 80ml of nitric acid acidified deionized water (pH=1) dissolved in 1g of iodic acid and 0.1g of iodine After hydrolysis and stirring for 3 hours, a uniformly dispersed emulsion was formed, and the resulting emulsion was transferred to a 250ml reactor for hydrothermal treatment at 70°C for 6 hours. Then 1g of iodic acid and 0.1g of iodine were dissolved into the emulsion after the hydrothermal treatment, and the solution was added dropwise to 70ml of an aqueous solution in which 6g of P123 surfactant was dissolved. The whole dropping process was stirred and dropped in a water bath at 50°C, stirred for 2h (uniformly), and then moved back into the reaction kettle for hydrothermal treatment at 150°C for 48h. Finally, the obtained emulsion was dried at 90°C and sintered at 400°C for 3 h (the heating rate was 3°C min -1 , with a cooling rate...

Embodiment 3

[0036] Dissolve 8ml of titanium tetrachloride in 20ml of ethylene glycol, stir for 3 hours to form a uniformly dispersed solution; then add dropwise to 80ml of deionized water acidified with hydrochloric acid (pH=5) for hydrolysis, and form a uniformly dispersed emulsion after stirring for 5 hours The resulting emulsion was transferred to a 250ml reactor for hydrothermal treatment at 120°C for 12h. Then 0.5g of thiourea and 0.8g of hexamethylenetetramine were dissolved into the hydrothermally treated emulsion, and the solution was added dropwise to 120ml of aqueous solution in which 5g of F123 surfactant was dissolved. The entire dropping process was stirred and dropped in a water bath at 60°C, stirred for 2h (uniformly), and then moved back into the reactor for hydrothermal treatment at 170°C for 36h. Finally, the obtained emulsion was dried at 90°C and sintered at 700°C for 5 h (the heating rate was 5°C min -1 , with a cooling rate of 4°C min -1 ), to obtain nitrogen-doped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com