Method for separating microorganism capable of producing ferulic acid esterase

A technology of ferulic acid esterase and ethyl ferulate, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as inability to intuitively judge, cumbersome steps, heavy workload, etc. High practical value, simplified screening process, shortened time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

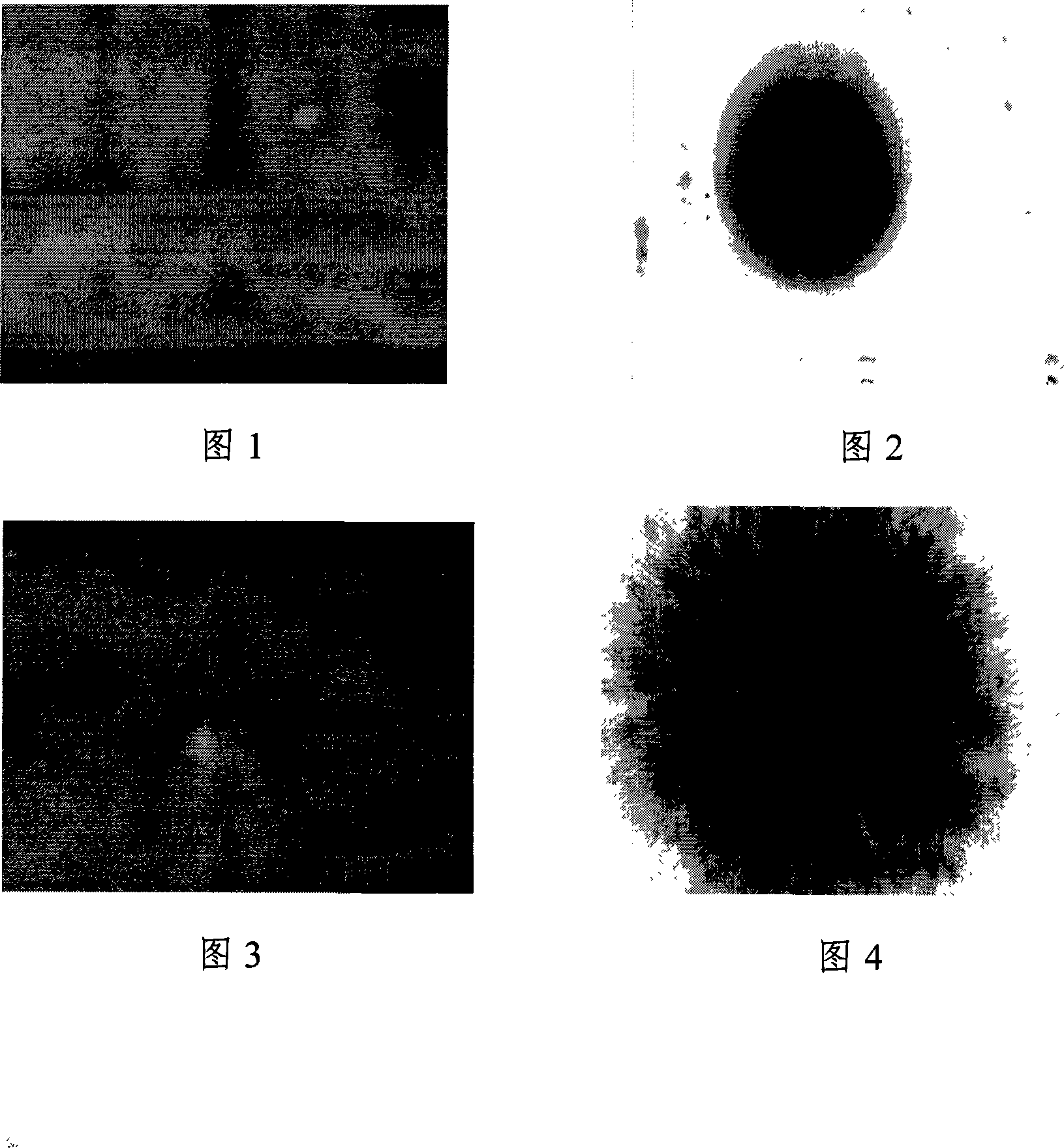

Image

Examples

Embodiment 1

[0027] Example 1 Preparation of Liquid Screening Medium

[0028] Add ethyl ferulate to conventional liquid selection medium without major carbon source (such as: glucose) to make the concentration of ethyl ferulate reach 2 μM. For example, the liquid screening medium with the following configuration is used, and each 1000ml contains: peptone 1.0g, yeast extract 1.0g, NaHCO 3 7.0g, crushed wheat straw 7g, solution I 165ml, solution II 165ml, cell-free rumen fluid 170ml, L-cysteine hydrochloride 1.7g, resazurin (0.1% w / v) 1.0ml, distilled water 500ml ; Solution I 1000ml contains: KH 2 PO 4 3g, (NH 4 ) 2 SO 4 3g, NaCl 6g, CaCl 2 2H 2 O 0.4g, MgSO 4 ·7H 2 O 0.6 g; solution II 1000ml contains: K 2 HPO 4 4g. Add penicillin (1600IU / mL) and streptomycin (2000IU / mL) before inoculation to inhibit bacteria.

Embodiment 2

[0029] Example 2 Preparation of solid screening medium

[0030] Add ethyl ferulate to conventional solid selection medium without major carbon source (such as: glucose) to make the concentration of ethyl ferulate reach 9 μM. For example, the solid screening medium with the following configuration is used, and each 1000ml contains: peptone 1.0g, yeast extract 1.0g, NaHCO 3 7.0g, 15g of agar, 165ml of solution I, 165ml of solution II, 170ml of cell-free rumen fluid, 1.7g of L-cysteine hydrochloride, 1.0ml of resazurin (0.1% w / v), 500ml of distilled water; solution I Contains in 1000ml: KH 2 PO 4 3g, (NH 4 ) 2 SO 4 3g, NaCl 6g, CaCl 2 2H 2 O 0.4g, MgSO 4 ·7H 2 O 0.6g; solution II 1000ml contains: K 2 HPO 4 4g. Add penicillin (1600IU / mL) and streptomycin (2000IU / mL) before inoculation to inhibit bacteria.

Embodiment 3

[0031] Example 3 Screening and isolation of anaerobic fungi producing ferulic acid esterase in bovine rumen microorganisms

[0032] 1) Collect fresh rumen fluid samples through ruminal fistula of cows, quickly inoculate 1 mL of it into a Heinz tube containing 9 mL of conventional liquid in vitro medium with a syringe, make gradient dilutions, and incubate at 39°C for 4 days;

[0033] 2) Inoculate the bacteria surviving in the Heinz tube with the highest dilution in a conventional liquid in vitro medium at a volume ratio of 1:9, and culture at 39°C for 4 days;

[0034] 3) Inoculate the bacterium into the liquid screening medium prepared in Example 1, and cultivate it at 39° C. for 3 days;

[0035] 4) Inoculate it into the solid screening medium prepared in Example 2, roll the tube on ice, and culture at 39°C for 2 days;

[0036] 5) Inoculate a single colony in the liquid screening medium prepared in Example 1, and culture at 39° C. for 3 days;

[0037]6) Repeat 4) and 5). Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com