Glutathione produced bacterial strain and construction method thereof

A technique for producing glutathione and bacterial strains, which is applied in the field of genetic engineering, can solve problems such as the inability to purposefully regulate cell expression, achieve high cell density, biotransformation rate, high bioaccumulation, and reduce synthetic production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

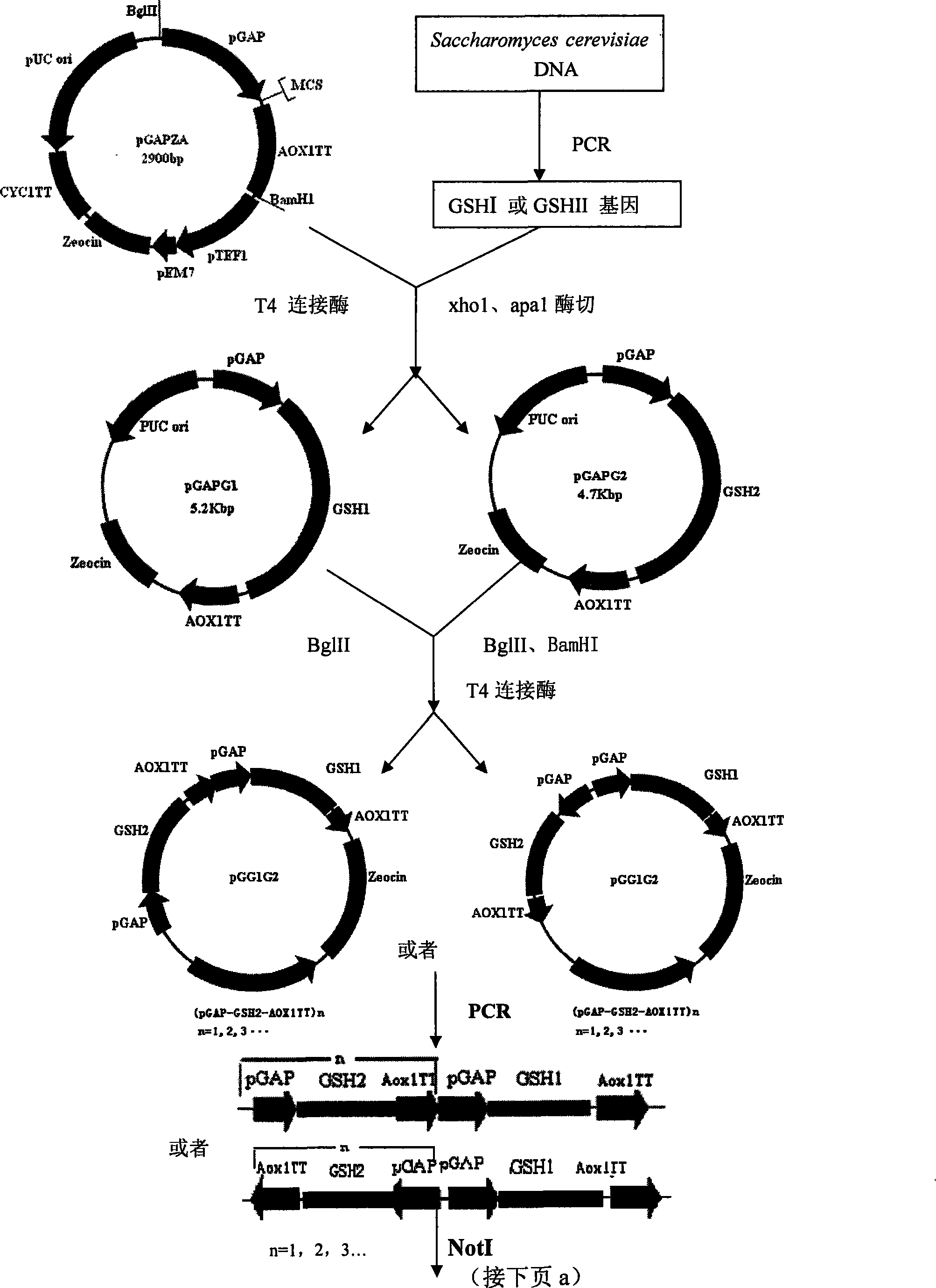

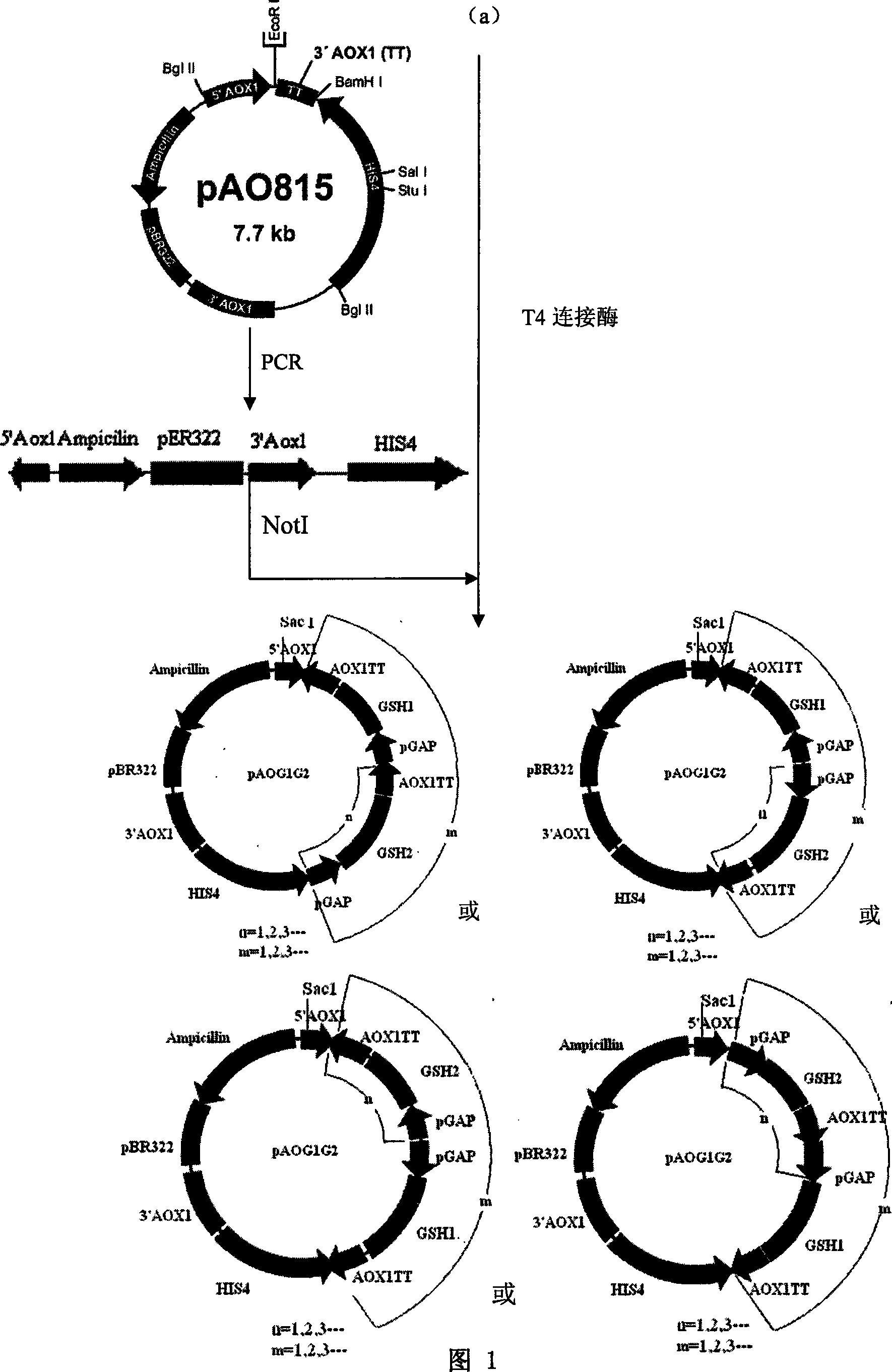

[0045] Example 1: Construction of recombinant GSH-related synthetase expression pAOG1G2 plasmid (scheme 1)

[0046] 1. Extraction of Saccharomyces cerevisiae genomic DNA

[0047] Saccharomyces cerevisiae genomic DNA was extracted according to the "Experimental Guide to Yeast Genetics Methods". Inoculate Saccharomyces cerevisiae S288c in 4ml of YPD medium (1% yeast extract, 2% peptone, 2% glucose), at 28-30°C for 16-18 hours. Take the culture solution and centrifuge the sedimented cells (3000rpm, 10min), then wash with cold, equal volume of sterile distilled water and centrifuge again, transfer the cell pellet to a 1.5ml centrifuge tube, in 200μl lysis buffer (2% (v / v) Triton X-100, 1% (v / v) SDS, 100mM NaCl, 10mM Tris base (pH8.0), 1mM EDTA (pH8.0)), then add about 300μl acid-washed glass beads and 200μl 1:1 phenol: chloroform mixture, vortexed for 1-2min, added 200μl of TE buffer (10mM Tris base (pH8.0), 1mM EDTA (pH8.0)), mixed by inversion 6-10 times. The samples were cen...

Embodiment 2

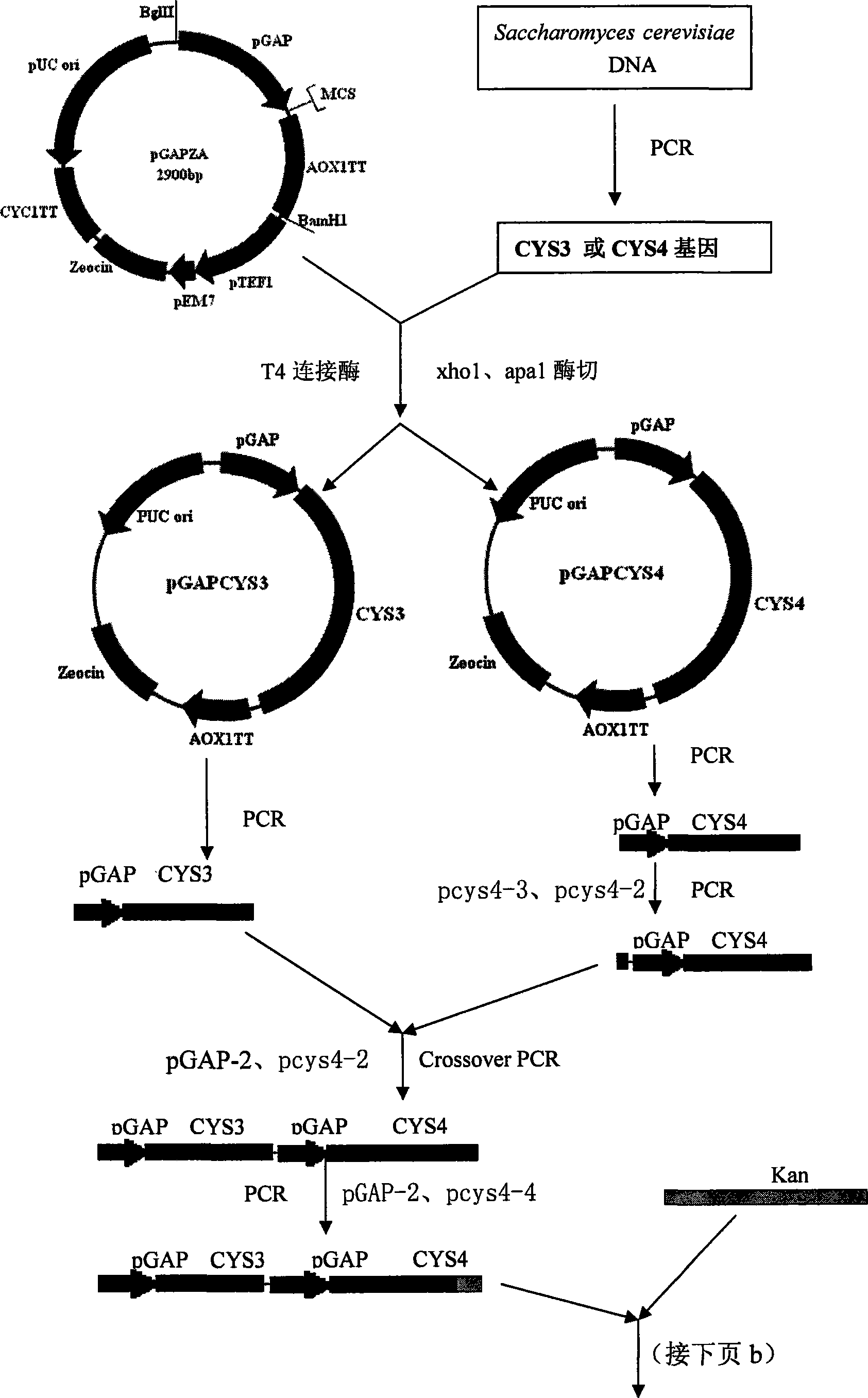

[0062] Embodiment 2: Construction of CYS3, CYS4 gene expression vector

[0063] 1. Extraction of the genome of the host strain Pichia pastoris GS115

[0064] The method is the same as the extraction of Saccharomyces cerevisiae genomic DNA in Example 1.

[0065] 2. Cloning of G418 resistance gene and CBS gene

[0066] The upstream and downstream primers were designed according to the plasmid pPIC3.5K, the upstream primer (5'sense primer) pkan-1TGAGGGAGCCACGGTTGATGAGAGC, the downstream primer (3'anti-sense primer) pkan-2GGGGTGTTATGAGCCATATTCAACG.

[0067] Using the plasmid pPIC3.5K as a template and the above primer pair as primers, Pyrobest polymerase was used to amplify the Kan fragment derived from the transposon Tn903 G418 resistance gene of Escherichia coli.

[0068] The upstream and downstream primers were designed according to the CBS gene of the GS115 strain genome (GenBank No.AF367364). The upstream primer (5′sense primer) pCBS-1 AGAAATACATACTATGTCAGACAACAACC, and the...

Embodiment 3

[0083] Example 3: Construction of recombinant cells expressing exogenous cystathionine synthase and cystathionine-γ-lyase genes

[0084] 1. Electroporation of Pichia pastoris cell preparation

[0085] Inoculate GS115 strain in 2ml YPD medium, culture at 30°C for 12-20 hours, inoculate in 100ml YPD medium at a ratio of 1:100, and culture at 30°C until OD 600 =1.3~1.5, 4°C, centrifuge at 1500g for 10min, suspend and wash the precipitate twice with pre-cooled sterile water, centrifuge at 1500g at 4°C for 10min, then suspend and wash the precipitate twice with pre-cooled 1mol / L D-sorbitol, After centrifugation at 1500 g for 10 min at 4°C, the obtained GS115 was resuspended in 0.3 ml of pre-cooled 1 mol / LD-sorbitol, and placed on ice until use.

[0086]2. Construction of recombinant cells expressing exogenous cystathionine synthase and cystathionine-γ-lyase genes

[0087] Use the PCR product gel recovery kit to extract about 10ug of the integrated expression vector PCR product of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com