Device and method for producing drinking ultra-light water

A production device and ultra-light water technology, applied in chemical instruments and methods, adsorption water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problems of low mineral content and inability to work for a long time, and improve the foundation Metabolism, enhance human immunity, enhance the effect of cellular immune function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

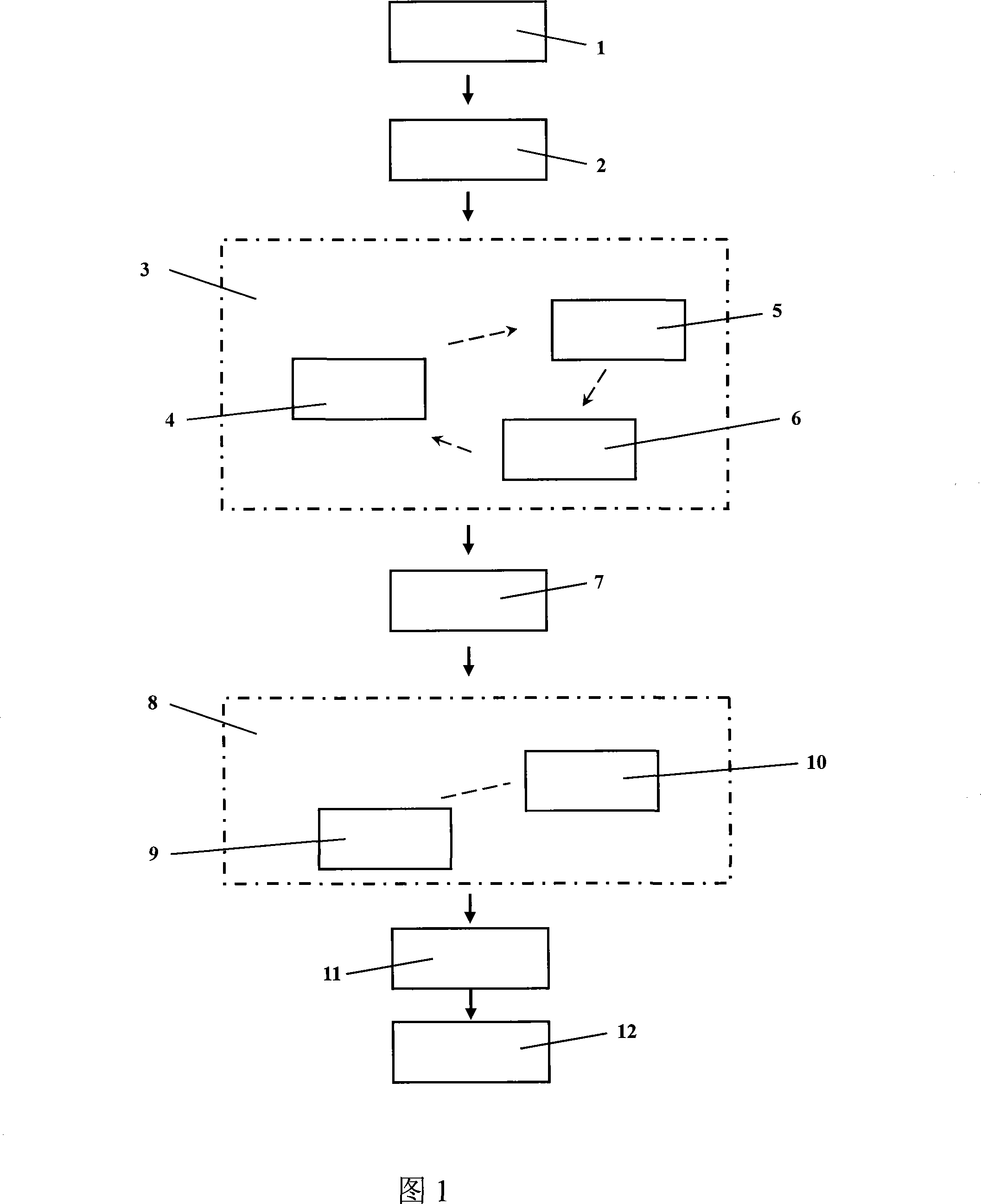

Method used

Image

Examples

Embodiment 1

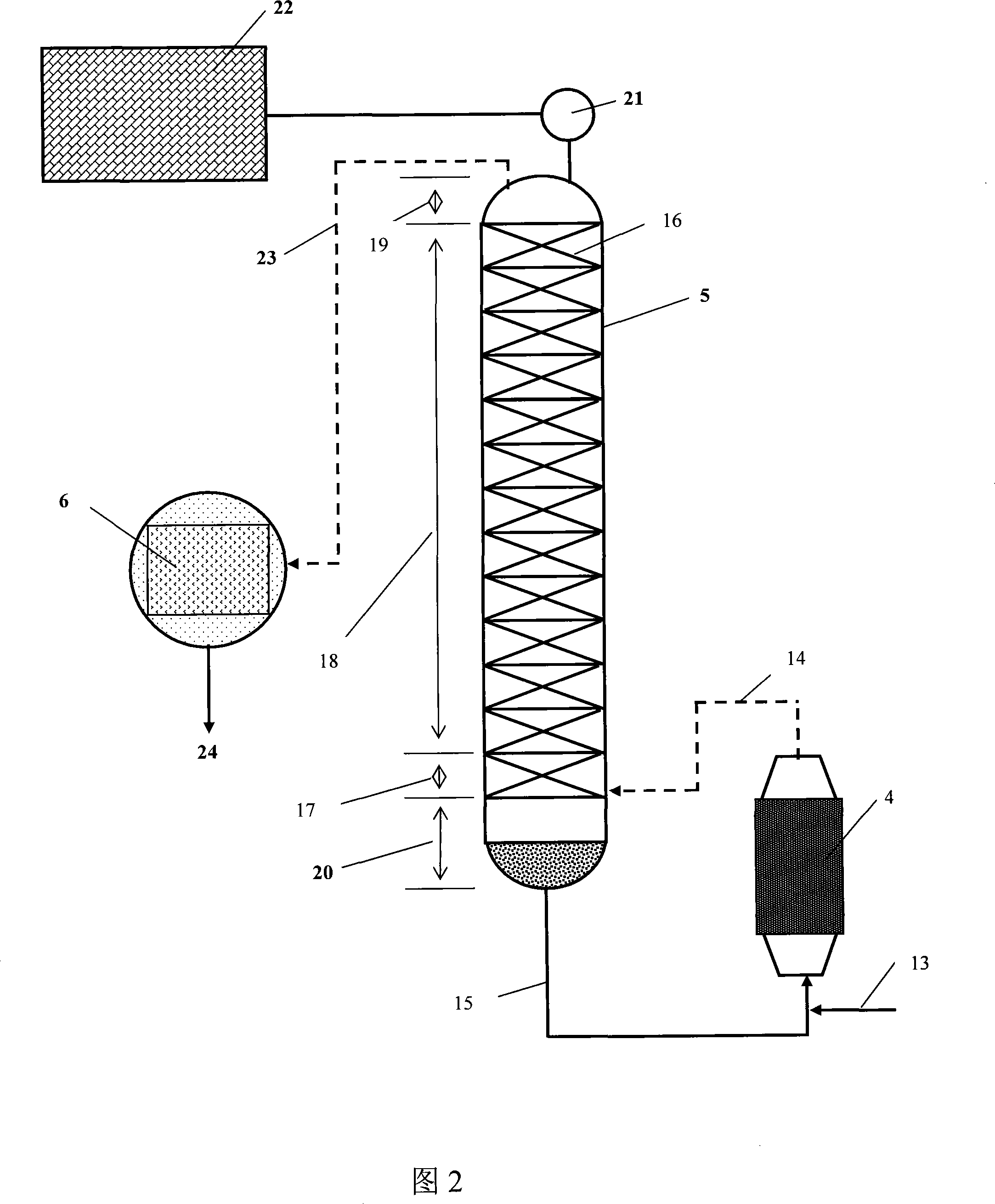

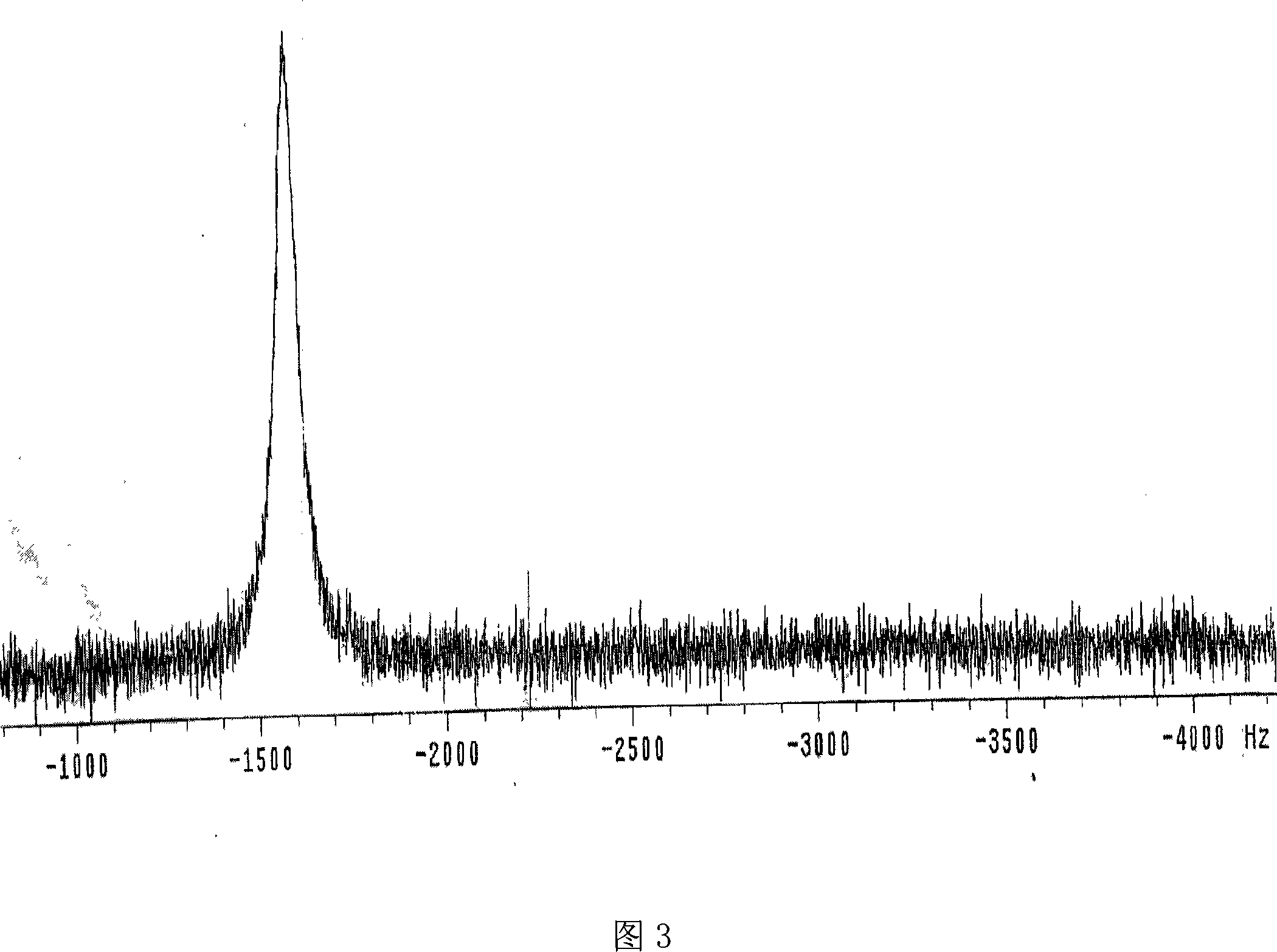

[0043] In the actual production process, the Yangtze River water is taken as the source water sample and pretreated by the hydraulic circulation clarifier and the ordinary fast filter to remove the large particle pollutants in the source water. Under the action of the pump, the pretreated source water enters the deuterium-depleted activation system at a flow rate of 2kg / h, undergoes a high-temperature reaction at 354.5K and a pressure of 1.06Mpa for 1 hour, and then is sent into the system at the original flow rate under the vacuum condition of the pump. Distillation device. Controlled vacuum distillation is carried out at an average of 72.3°C and 120mmHg vacuum pressure. Immediately after high-precision vacuum distillation, the water sample is subjected to high-speed centrifugation treatment, and the processing parameters are controlled at 10000r / min and 15.6bar. After high-speed centrifugation, the water sample part is circulated in the deuterium-depleted activation system,...

Embodiment 2

[0045] The water from the Yangtze River was taken as the source water sample, which was pretreated by polyaluminum chloride flocculation clarification and activated carbon filtration. The pretreated water sample enters the deuterium-depleted activation system at a flow rate of 3kg / h, and undergoes a high-temperature reaction for half an hour. The temperature and pressure conditions are controlled at 450K and 1.77Mp, respectively. After the reaction, the water sample enters the rectification device with a flow rate of 3kg / L by the pump under vacuum conditions. High-precision vacuum distillation is carried out at 87°C and 180mmHg. The water sample after rectification is subjected to high-speed centrifugation under the conditions of 20000r / min and 17bar. The water samples circulated in the deuterium-depleted activation system enter the comprehensive filtration system at a flow rate of 1.3kg / h. After being treated by the 30barM30 nanofiltration membrane, they are contacted and mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com