Method for preparing fluorescent rare earth complex compound silicon nano particles

A technology of silicon nanoparticles and complexes, which is applied in the field of preparation of fluorescent silicon nanoparticles, to achieve the effect of improving fluorescence intensity, easy realization, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

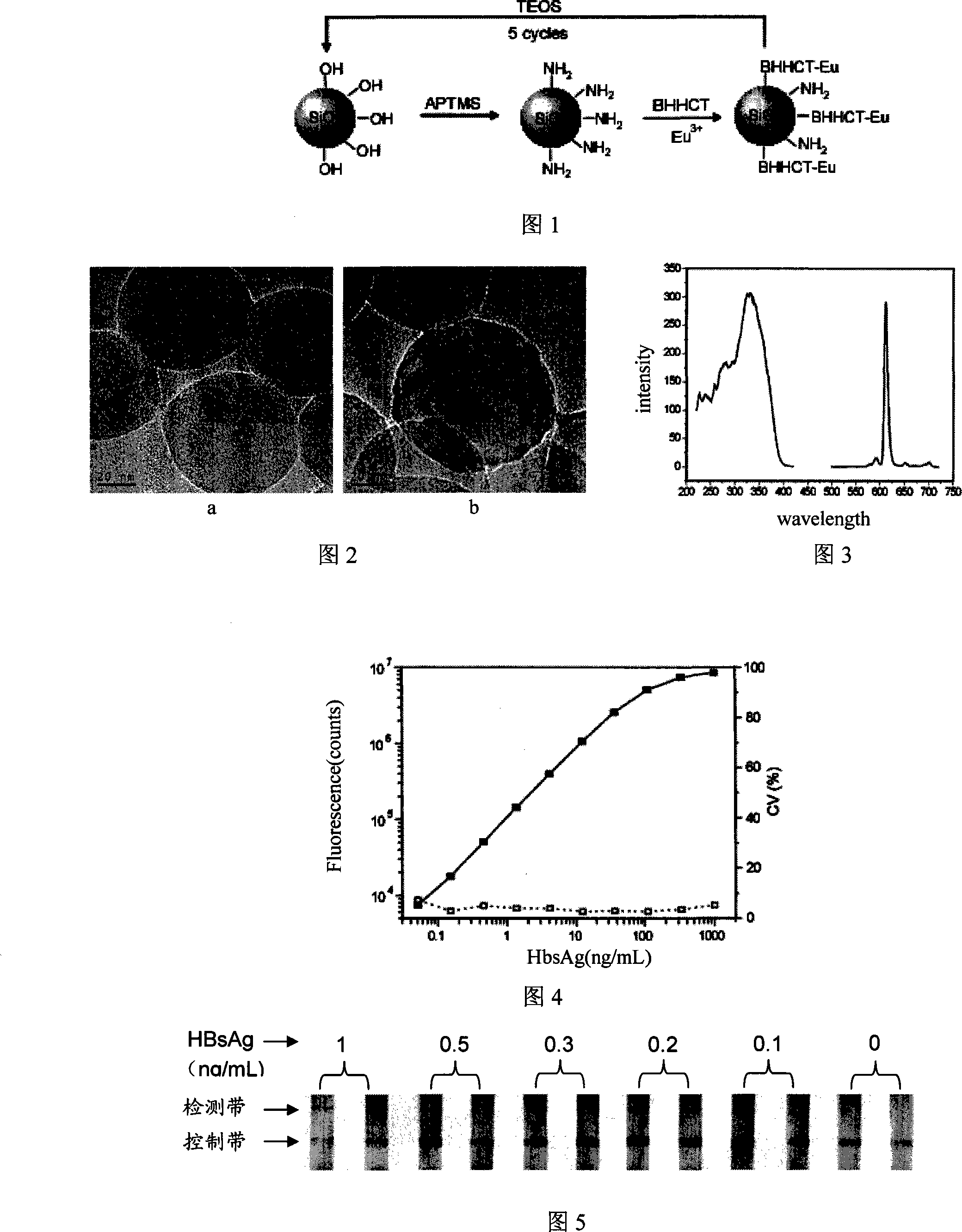

[0043] Embodiment 1: Preparation of BHHCT-Eu silicon nanoparticles

[0044] This example describes the preparation of silicon nanoparticle carriers by the inverse microemulsion method, using APTMS to modify amino groups on the surface of the particles, using BHHCT with sulfonyl chloride groups as the bonded rare earth ligands, and using Eu 3+ Preparation process of fluorescent rare earth complex silicon nanoparticles for rare earth ions.

[0045] (1) Preparation of silicon nanoparticle carrier: Take 30mL of cyclohexane, 10mL of Tx-100, and 10mL of n-hexanol into the Erlenmeyer flask, place it on a magnetic particle stirrer and stir, after stirring evenly, add 2mL of ultrapure water and 300μL of ammonia water in turn , 800μLTEOS, after stirring for 24 hours, add an equal volume of acetone, mix well, centrifuge to separate the particles, then wash the particles several times with ultrapure water and absolute ethanol to remove surfactants and other unreacted reagents, and finally...

Embodiment 2

[0051] Embodiment 2: Preparation of BC-EDTA-Eu silicon nanoparticles

[0052] This example describes the preparation of silicon nanoparticle carriers by the inverse microemulsion method, using APTMS to modify the amino group on the surface of the particles, using BC-EDTA as the bonding rare earth ligand, and using Eu 3+ Preparation process of fluorescent rare earth complex silicon nanoparticles for rare earth ions.

[0053] (1) Preparation of silicon nanoparticle carrier: Same as Example 1.

[0054] (2) Amination of the surface of silicon nanoparticles: same as in Example 1.

[0055] (3) Chemical bonding of fluorescent rare earth complexes: take 1 mL of silicon nanoparticles modified with amino groups on the surface, the concentration is 15 mg / mL, wash twice with 0.05 mol / L phosphate buffer saline (PBS), pH=6.8 , ultrasonically suspended in 1 mL of 0.05 mol / L PBS. Take another 3.4mg BC-EDTA (2,9-bis[N,N-bis(carboxymethyl)aminomethyl]-4,7-diphenyl-1,10-phenanthroline), 0.4mg...

Embodiment 3

[0059] Embodiment 3: Preparation of BBCAP-Eu silicon nanoparticles

[0060] This example describes the preparation of silicon nanoparticle carriers by the inverse microemulsion method, using APTMS to modify the amino groups on the surface of the particles, using BBCAP as a bonded rare earth ligand, and using Eu 3+ Preparation process of fluorescent rare earth complex silicon nanoparticles for rare earth ions.

[0061] (1) Preparation of silicon nanoparticle carrier: Same as Example 1.

[0062] (2) Amination of the surface of silicon nanoparticles: same as in Example 1.

[0063] (3) Chemical bonding of fluorescent rare earth complexes: Take 1 mL of silicon nanoparticles modified with amino groups on the surface, the concentration is 15 mg / mL, wash with 0.05 mol / L carbonate buffer (CB), pH=9.5, wash twice Repeatedly, ultrasonically suspend in 1 mL of 0.05 mol / L CB. Take another 2.6mg BBCAP (2,9-bis[N,N-bis(carboxymethyl)aminomethyl]-1,10-phenanthroline), 0.4mg NHS, 3.9mg EDC,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com