Precious metals smelting method for anode sludge or nonferrous smelting slag

A smelting method and anode slime technology, applied in the direction of improving process efficiency, etc., can solve the problems of difficult comprehensive recovery, high production cost, high pollution, etc., and achieve the effect of wide application range and pollution avoidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

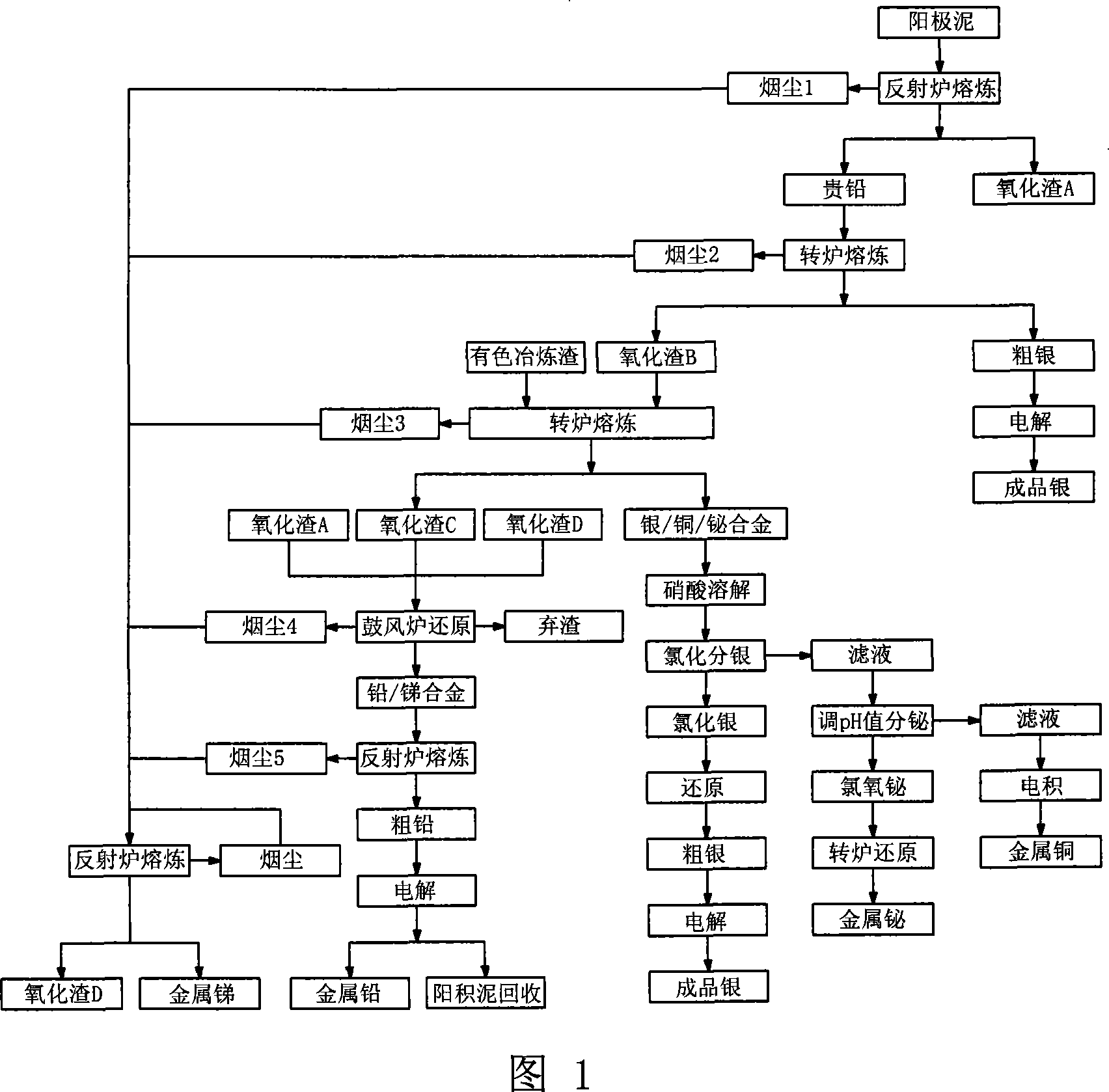

[0030] Precious metal smelting of lead anode slime

[0031] (1) Put the lead anode slime into the reverberatory furnace, complete the reduction smelting at 1000℃~1200℃, and then oxidize and blow most of the antimony at 700℃±200℃ to form noble lead rich in silver and mainly containing Lead (Pb) and antimony (Sb) oxide slag A, wherein the silver content in noble lead is about 8-15%.

[0032] (2) Put the precious lead obtained in step (1) into the converter, and oxidize and blow it at a temperature of 800-1200° C. to produce crude silver containing 90-98% silver and mainly containing lead (Pb), copper ( Cu), antimony (Sb), bismuth (Bi) oxide slag B, crude silver electrolysis output 1 # silver.

[0033] (3) Add the oxidized slag B produced in the previous step into the converter, melt it at a temperature of 1000°C to 1200°C through the converter, and oxidize it by blowing air on the surface of the melt. After the slag layer is formed, the slag is discharged, and after the slag i...

Embodiment 2

[0038] Precious metal smelting of copper anode slime

[0039] (1) Put the copper anode slime into the reverberatory furnace, reduce and smelt at 1000℃~1200℃, remove selenium at the same time, and then oxidize most of the antimony at 700℃±200℃ to form noble lead rich in silver And oxide slag A mainly containing lead (Pb) and bismuth (Bi), wherein the silver content in noble lead is about 8-15%.

[0040](2) Put the precious lead obtained in step (1) into the converter, and oxidize and blow it at a temperature of 800-1200°C until crude silver containing 90-98% of silver and mainly containing lead (Pb), copper ( Cu), antimony (Sb), bismuth (Bi) oxide slag B, crude silver electrolysis output 1 # silver.

[0041] (3) Put the oxide slag B containing lead (Pb), copper (Cu), antimony (Sb), and bismuth (Bi) into the converter, melt it at a temperature of 1000 ° C to 1200 ° C through the converter, and blow it to the surface of the melt for oxidation , After the slag layer is formed, ...

Embodiment 3

[0046] Precious metal smelting of copper slag

[0047] (1) Copper slag is oxidized and blown in a converter to produce silver-copper-bismuth alloy and oxide slag C mainly containing lead and antimony; the specific method is the same as step (3) in Example 1.

[0048] (2) The silver-copper-bismuth alloy obtained in step (1) is separated from various metals in the alloy by a wet method; the specific method is the same as step (4) in Example 1.

[0049] (3) The flue dust obtained in step (1) smelting in the intermediate converter is reduced by a reverberatory furnace to obtain metal antimony and oxide slag D mainly containing lead (Pb) and antimony (Sb).

[0050] (4) The oxidized slag C mainly containing lead and antimony obtained in step (1) is reduced into a lead-antimony alloy through a blast furnace together with the oxidized slag D, and the lead-antimony alloy is chased by a reverberatory furnace to obtain crude lead, and the crude lead is electrolyzed Metal lead and anode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com