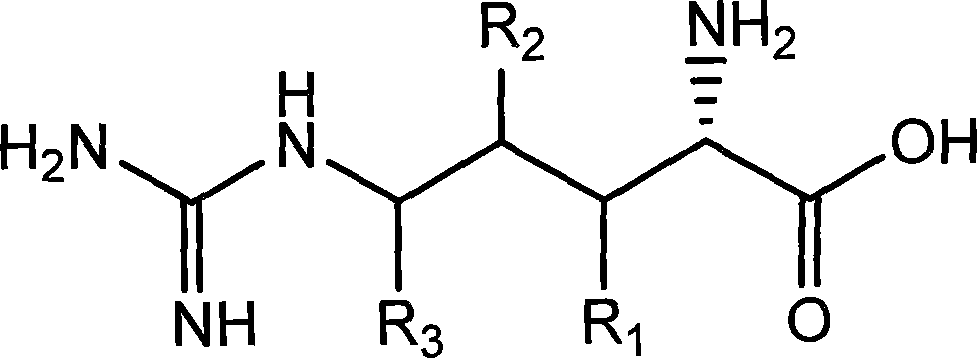

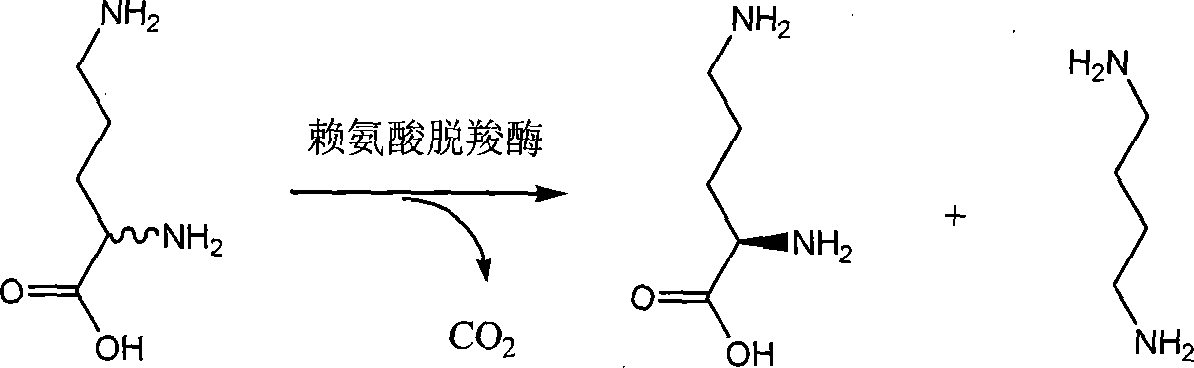

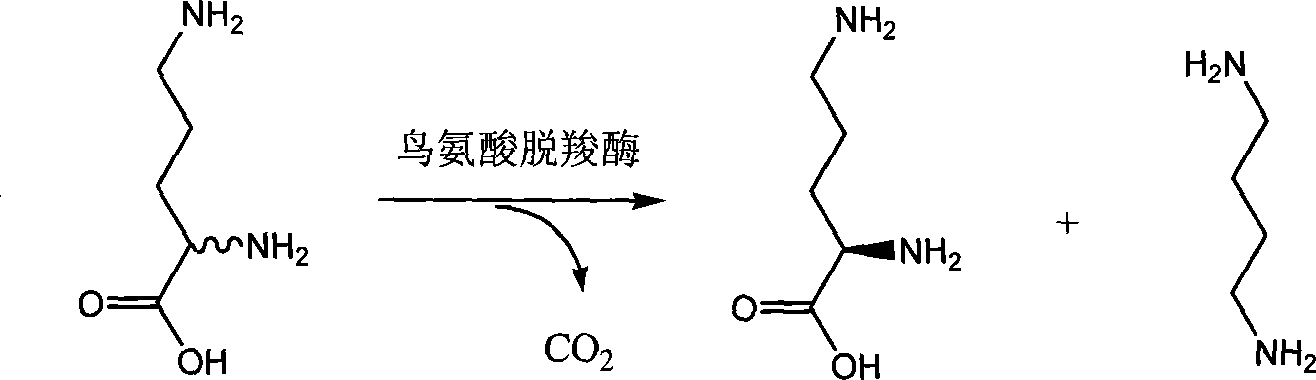

Chiral method for preparing D-ornithine and putrescine or derivatives thereof

A derivative, ornithine technology, applied in the field of biotransformation and separation of chiral compounds, can solve the problems of inconvenient to obtain polyamine compounds, inability to prepare D-ornithine, environmental pollution, etc., and achieves short conversion time and low price. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1. Put the Hafnia alvei AS 1.1009 bacterial strain in the following 1000mL culture medium: 2% sucrose, 1% peptone, 2% corn steep liquor, 0.1% yeast extract, (NH 4 ) 2 SO 4 0.1%, L-Lysine 1%. The fermentation conditions are as follows: temperature 35°C, inoculum size 6%, medium loading volume 100mL, fermentation time 14h. Wet cells were obtained by centrifugation at 4000rpm for 15min.

[0044] 2. Add cells to 600mL transformation solution containing 10% DL-ornithine obtained by racemization reaction, add 6mL 0.5% Tween-80 and 600mL pH8.0 phosphate buffer, and react at 37°C 24h. .

[0045] 3. Concentrate the conversion solution to 200 mL, add 2 g of activated carbon for decolorization. Continue to concentrate the decolorized solution to 100mL, add 200mL of 95% ethanol and stir evenly, cool and crystallize, filter and dry in vacuum to obtain a dry weight of 37.5g of crystals, [α] D 20 =-11.5 (C=5.5, H 2 (0), the gained mother liquor is adsorbed by JK008 cationic ...

Embodiment 2

[0047] 1. Select the Hafnia alvei AS 1.1009 bacterial strain, the seed culture and fermentation conditions are the same as in Example 1, and wet cells are obtained.

[0048] 2. Add the cells to 600mL transformation solution containing 10% DL-ornithine obtained by racemization reaction, add 6mL 0.1% cetyltrimethylammonium bromide and 600mL pH7.0 diphosphate Sodium hydrogen-citric acid buffer solution, react at 30°C for 36h.

[0049] 3. Concentrate the conversion solution to 200 mL, add 2 g of activated carbon for decolorization. Continue to concentrate the decolorized solution to 100mL, add 200mL of 95% ethanol and stir evenly, cool and crystallize, filter and dry in vacuo to obtain 30.1g of crystal dry weight, [α] D 20 =-10.8 (C=5.5, H 2 (0), the obtained mother liquor is adsorbed by JK008 cationic resin, eluted with 3% ammonia water, and the eluent is decolorized by activated carbon and then concentrated, and the concentrated solution is adjusted to pH 10 to obtain putresc...

Embodiment 3

[0051] 1. Put the Hafnia alvei AS 1.1009 strain in the following 1000mL medium: 2% glucose, 1% soybean cake hydrolyzate, 2% corn steep liquor, 0.1% yeast extract, (NH 4 ) 2 SO 4 0.1%, L-ornithine 0.5%. The fermentation conditions are as follows: a temperature of 35° C., an inoculum size of 5%, a culture medium loading capacity of 100 mL, and a fermentation time of 20 h. Wet cells were obtained by centrifugation at 4000rpm for 15min.

[0052] 2. Add the cells to 600mL of transformation solution containing 10% DL-ornithine obtained by racemization reaction, add 6mL of 0.5% Tween-80 and 600mL of pH9.0 borax-hydrochloric acid buffer solution, 40°C Reaction 48h.

[0053] 3. Concentrate the conversion solution to 200 mL, add 2 g of activated carbon for decolorization. Continue to concentrate the decolorized solution to 100mL, add 200mL of 95% ethanol and stir evenly, cool and crystallize, filter and vacuum dry to obtain a crystal dry weight of 35.5g, [α] D 20 =-11.2 (C=5.5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com